It’s quite a feat to be the builder of what could easily be said as “the world’s most popular wheel.” The wheel? The Torq Thrust. The maker? American Racing [2]. The iconic five-spoke wheel has been found on more hot rods and muscle cars than any other wheel. It is the wheel most emulated, pirated and blatantly ripped-off. It’s the hot rod wheel. If you’re a wheel maker catering to the hot rodding market, chances are you’ve got something just like it. If you’re American Racing, you’ve had it since 1958.

[3]

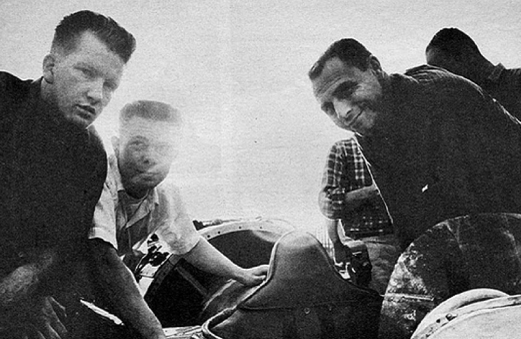

[3]Romeo Palamides (center) made a career out of designing and building custom machines like the ill-fated 'Infinity' land-speed record contender before co-founding American Racing. Image: samuelhawley.com

The brand, American Racing came about out of necessity back in 1954, when Romeo Palamides and J.O. “Jim” Ellison teamed up to build a fuel dragster. Palamides had developed a name for himself building customs and race cars when the notion came to him to start building dragster chassis.

Looking to shave weight every which way he could, Palamides contracted San Francisco machine-shop owner Jim Ellison – along with engineering innovator Tom Griffith – to help design a wheel that would be as lightweight as possible while maintaining exceptional strength.

The result was true performance dragster that featured a set of purpose-built magnesium wheels that boasted “an enviable strength-to-weight ratio.”

Ironically, it wasn’t the dragster that sparked a wildfire of popularity for the trio, but the rims. When the car was featured on the November 1956 cover of Hot Rod Magazine, a flood of orders for the wheel birthed American Racing Wheels.

Since those fledgling days back in 1956 until today, the company has stayed in operation in California making it the longest continuously operating aftermarket wheel maker in the United States.

By the time 'Bullitt' came out in 1968, the Torq Thrust wheel had permeated nearly every sphere of hot rodding. Featured on the quintessential 'hero car,' all Mustangs made to emulate the movie sported American Racing's infamous wheel. Steve McQueen would approve.

Enter The Torq Thrust

Although not American Racing’s first design, the five-spoke Torq Thrust wheel has been its most popular. In a time when wheel choices consisted of either factory wheels, slightly modified factory steelies with aftermarket or off-brand caps, or expensive semi-solid, modular European racing wheels, the introduction of an American-made lightweight aftermarket wheel shook the hobby.

[6]

[6]Described only as an "engineering innovator," Tom Griffith was responsible for the Torq Thrust rim that nearly single-handedly birthed the aftermarket wheel industry.

Griffith’s design was both simple and revolutionary, the Torq Thrust featured five tapered, parabolic contour spokes that not only reduced overall wheel weight but allowed great brake cooling.

Available either completely polished or from lightweight anthracite and a polished rim, the Torq Thrusts found themselves on dragsters, diggers, rails, lakesters, street rods, and lead sleds, basically everywhere.

This was nowhere more evident in 1968 film “Bullitt” staring the car and motorcycle aficionado, Steve McQueen. Sqauring up against a brand-new 440-powered R/T Dodge Charger, McQueen’s “Frank Bullitt” piloted a Highland Green ’68 GT 390 fastback fitted with American Racing’s Torq Thrusts. Since then, all “Bullitt” clones and even Ford’s “Bullitt” edition Mustangs have all required the legendary wheel to be “correct.”

Today, original Torq Thrusts are highly collectible items, particularly due to their brief discontinuance during the 1970s despite their presence and look made them wholly synonymous with nearly any five-spoke wheel.

It was because of this demand that the Torq Thrust was revived in the 1980s, although slightly modified. Now offered in a D-Spoke variation wherein the spokes were relieved to clear modern disc brakes, the returning Torq Thrust accompanied several styles including the 200S (better known as the “Daisy”) and the Ansen Sprint.

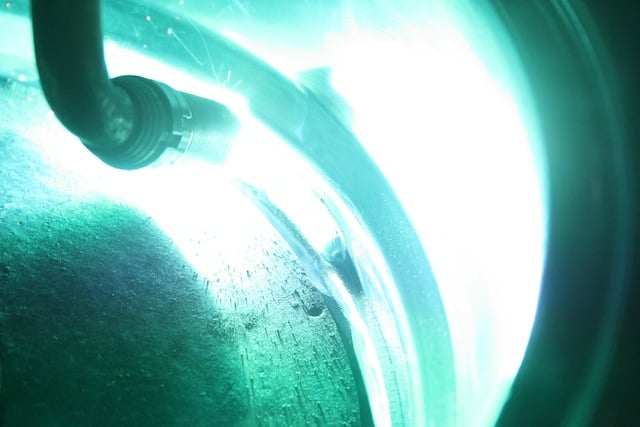

Comprised of a cast center and a machined hub, American Racing's two-piece rims are quickly hand-assembled whether for mass production or individual custom orders, such as these Salt Flat Specials.

Part of a Bigger Family

[9]Today’s American Racing is part of the Wheel Pros family, but is still producing the same quality race and enthusiast-level wheels that its starting making way back in that San Francisco speed shop over 55 years ago, just alongside Wheel Pros’ other brands in its Cerritos, CA facility.

[9]Today’s American Racing is part of the Wheel Pros family, but is still producing the same quality race and enthusiast-level wheels that its starting making way back in that San Francisco speed shop over 55 years ago, just alongside Wheel Pros’ other brands in its Cerritos, CA facility.

We talked with Wheel Pros’ Communications Director, Jen Horsey who explained, “American Racing is part of the Wheel Pros family of brands, which includes ATX, Motegi, KMC. It is the largest wheel company in the world, with manufacturing facilities, company owned warehouses, and an independent distributor system in the United States and more than 20 countries on four continents.”

Yet, that doesn’t mean American Racing has swayed from it’s roots. When we talked to Rhett Sander, Wheel Pros Marketing Director, he explained, “American Racing is in drag racing because it’s fundamental to who we are. Making wheels for drag racing is how the company got its start back in the 1950s, and a partnership with a legend like Tony Pedregon is something that is very true to our roots. Look at the team’s funny car: the rat-rod themed livery pays homage to the early days of American Racing.”

“Similarly, it’s important for us to support athletes and personalities that speak to the core values of each of our Wheel Pros brands,” Rhett continued. American Racing, as well as Wheel Pros other brands support other racers and athletes like Tony Hawk, Gerald Swindle, Travis Pastrana, and pretty much everybody who’s sponsored by Red Bull.

Before being married to its respective hub, each cast center is individually chamfered to allow for better weld penetration.

We'll admit it, we couldn't get enough of photographing this amazing process. A pair of gas torches heat up the machined hub, relaxing the steel up nearly .030ths of an inch, allowing the cast center to be inserted.

Putting The Pieces Together

There is something beautifully uncomplicated about how American Racing assembles there more classic lines like the Torq Thrust, 200S, Salt Flat Special, Hopster, and Vn500 designs. These two piece designs are assembled within a three-to-four minute process and with surprising ease.

[16]

[16]Every wheel is personally expected and dial-checked to ensure that the center is...well, centered.

All of American’s two-piece designs have their centers cast offsite while another division machines all of the outer rims.

Each of these components come in a variety of finishes, be it brushed, gray or polished, satin or gloss black, and can be custom mixed and matched only through American Racing’s new Custom Shop.

Each and every wheel is hand-assembled, polished and packaged, ensuring that several eyes review each rim before it ships out to its destination.

Upon receiving an order, a coded cast center is taken over to assembly, where the inside edges are chamfered using a DA sander. This rounding of the edges will ensure that the bead weld that bonds the center to the hub will penetrate deep enough.

Before that step though, the matching machined hub is set on a heating table, where a pair of butane torches heat up the spinning hub until it has expanded upwards to .030ths in diameter.

This will allow the center to be set inside of the super-heated rim on the cooling table. The machined surface is squared and level with a pedestal where the center is positioned inside of the hub. With a flip of a switch, cool compressed air blows through the rim, immediately cooling – and thereby shrinking – the rim around the center section.

Each rim is then methodically MIG welded together, cast center to machined hub. The bead is a deep, thick overlapping bond that ensures tougher-than-nails durability. Each weld is individually inspected before going off to finishing.

Sealing The Deal

Once assembled, the wheel is checked on two axis to verify that the center is aligned with the hub, and that the hub is not out of round. When checked, the wheel is cleaned and set on the welding table, where a MIG welder runs a consistent bead along the inward seam between the center and the rim. Marrying the two surfaces together, the now permanently-bonded wheel is handed over to finishing, where it is polished, packaged and boxed, ready for shipping.

[21]Of course, that’s not how all of American Racing’s wheels are built, particularly as so many of the brand’s wheel designs are forged and/or CNC-milled such as their stunning Daytonas, or the more modern-styled Burnouts and Circuits.

[21]Of course, that’s not how all of American Racing’s wheels are built, particularly as so many of the brand’s wheel designs are forged and/or CNC-milled such as their stunning Daytonas, or the more modern-styled Burnouts and Circuits.

Because of the varied processes, the Wheel Pros facility has a high-speed three-axis computer-programmed digital mill that can run through a program with lightning speed resulting in a finished and ready-to-ship wheel.

Despite all of the imitations, the knock-offs and the wannabes, there’s no mistaking the American Racing name. Made entirely in America, the brand that nearly created the aftermarket wheel industry in hot rodding is still cranking out the classics along with some seriously cool wheels that just at home on a vintage ’33 Ford as they would a ’68 Chevelle or a ’09 Challenger; it’s timelessness of American Racing’s designs and the company’s legacy of building the wheels car lovers want.

Each wheel is then hand-polished, wrapped and packaged. Oh yeah, and you can't forget the center cap. American Racing offers a selection of classic caps and knock offs that will work for your custom rod, restoration or street machine.

When it comes to building legends, it's hard to argue with American Racing's record. 'The Torq Thrust was designed in the 1950s... It looked rad and it worked, and everybody had to have it,' Rhett continued. 'Since then, it has become the most recognized wheel in the world and we're proud to say we've been producing that original iconic wheel for more than 50 years.'