If you’re bringing a classic Chevy [1] into the 21st century, ride, handling, and chassis updates are probably at the top of your list. There are several options out there when it comes to modernizing the chassis geometry of your ride, but Chris Alston and Chassisworks [2] have a way of pinpointing the needs of builders and providing enthusiasts with solutions to handling woes whether it be street, strip, or track.

Catering to the classic Chevrolet addicts out there, Chassisworks Torque Arm g-Link Suspension systems “directly replaces the the OEM leaf springs and shocks for significant performance increases in cornering ability, throttle response, and braking stability,” according to Chassisworks.

The kits are comprised of a fabricated, longitudinal torque arm, tubular steel or billet aluminum lower arms, a Watt’s link location bracket, a splined billet-end anti-roll bar, weld-on shock mounts, and VariShock [3] coilovers. So, if you have a ’67 to ’81 Firebird or ’62 to’71 Chevy II or Nova, we’re talking to you.

[4]

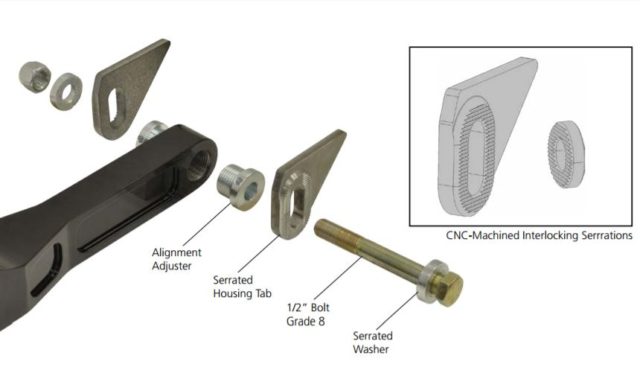

[4]Here we see an exploded view of the side-to-side torque arm adjustment mechanism. Threaded bosses allow the setup to be shifted, then locked down with a splined bracket and washer.

In these two videos, we are presented real-world stop motion animations of the dynamic adjustments available to builders when dialing in your Chassisworks gStreet torque arm [5] setup. To paraphrase Chassiworks, the torque arm is a traction device like old-school ladder bars or traction bars. The forces an automobile exert on the road and itself can’t be removed, but they can be harnessed and sometimes repurposed. The torque arm takes the wheel-spinning torque at your tires and directs it to the road for enhanced launches, acceleration, and cornering traction. Conditions like axle wrap are a result of inferior chassis geometry and security, translating into chatter down the drag strip, or uncontrolled cornering. These uncontrolled axle movements can be tamed with a torque arm setup.

[6]In the first video, we see the side-to-side adjust ability of the torque arm. This adjustment allows the builder to locate the front Pivotball mount. Threaded bosses and locking serrations allow precise left/right movement before being tightened down.

[6]In the first video, we see the side-to-side adjust ability of the torque arm. This adjustment allows the builder to locate the front Pivotball mount. Threaded bosses and locking serrations allow precise left/right movement before being tightened down.

The side-to-side adjustment allows you to align the front end of the Pivotball with the fixed chassis mounting bracket. Ultimately, the squareness of the wheelbase is driven by this adjustment, influencing handling characteristics.

The second video details the pinion angle adjustment feature of the gStreet torque arm. At the rear of the torque arm, the fabricated structure rides a pivot bolt at the pinion output of the differential. Under the centerline of the differential is a locking bolt and similarly broached locking splines, which, when clamped together, secures the pinion angle in space. By tuning these simple adjustment parameters, car setup can be finely tuned to offer better launches and control under various driving conditions.

For more information on the design, theory, and tuning of modern suspension and chassis solutions, or how you can modernize your classic musclecar or Chevy hot rod, check out Chassisworks [8].