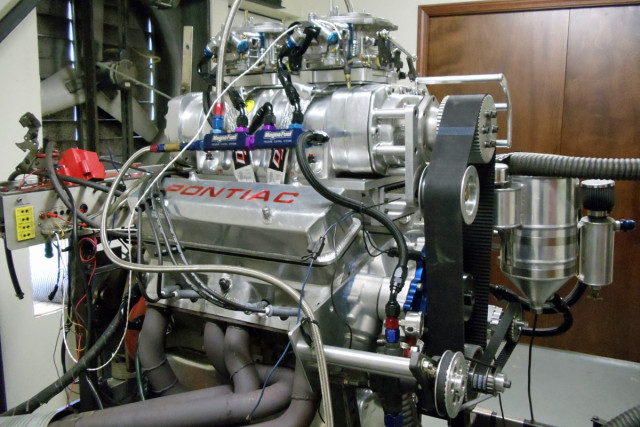

The Pontiac engine, despite its status as ‘no longer produced’ by General Motors, still enjoys a strong following in the drag racing world. Mark and Jeff Kauffman at Kauffman Racing Equipment [1] do one thing, and do it well–specialize in building big horsepower for Pontiac customers all over the world, and this example is no different.

This particular blown beast displaces 516 cubic inches and is based around one of Kauffman Performance’s MR-1A aftermarket Pontiac blocks designed to handle the big power. How much power, you ask? How does 1,410 horsepower at 7,000 rpm and 1,162 lb.-ft. of torque at 5,500 rpm sound? You’ll have to click the videos to find out.

Destined for installation into a customer’s 1964 GTO, the engine makes this big number with only 10 pounds of boost pressure in a 4 percent underdriven configuration.

Inside the engine, KRE selected a Crower [2] 4.550-inch stroke billet crankshaft, GRP [3] billet-aluminum connecting rods, and Ross [4] pistons to fill the 4.250-inch cylinder bores and round out the displacement.

Induction on a blown engine is critical–despite the supercharger artificially enhancing the engine’s atmosphere, the cylinder heads and camshaft must work together to ensure the performance goals are met. To that end, a set of KRE [1] 430 High Port cylinder heads are used in this application, with one of KRE’s custom-ground, secret-squirrel-spec 55mm solid roller camshafts on board.

The cylinder heads sport CNC-machined chambers for consistency. Despite the killer performance they offer, they still bolt to any and all traditional Pontiac blocks and do not require any special trickery like offset lifters or shaft rocker systems, although those items can be used if necessary for the particular application’s durability purposes. Shaft rockers are used in this engine due to its extreme nature.

The 14-degree valve angle promotes flow, while the exhaust port is a standard Pontiac round-port style to accept the vast majority of headers on the market. These KRE High Port heads are capable of flowing 430-plus cfm in CNC-ported configurations as used here.

Topping off the induction system is one of KRE’s billet blower intake manifolds designed for this application. The KRE manifold solves a large problem that Pontiac lovers have when desiring a large roots-style supercharger atop their engine.

Other blower manifolds on the market only provide enough clearance for 8-71 style superchargers, but by tuning up the manifold’s design in Mastercam modeling software, the KRE team was able to build in the necessary distributor clearance for the much-larger 14-71 blower case to be used.

Speaking of the 14-71, Littlefield [7] provided the huffer that’s on top of this engine.

“This intake will support 2,000-plus horsepower, and provides an RPM range from 4,000 to 8,000 RPM,” says KRE’s Jeff Kauffman.

The engine runs on methanol fuel for a number of reasons, one of which is its ability to help keep the intake charge cool, a major concern with roots-blown applications that generate massive amounts of heat as a byproduct of the supercharging process.

“The methanol helps us to produce big torque numbers, and will also help the engine to run more consistently, especially when it’s hot during the summer,” says Kauffman.

Feeding the big blower are a pair of Quick Fuel Technology [8] 1050 cfm carburetors optimized for the methanol, which requires much greater volume to work properly in a racing application. As methanol holds approximately half the energy content as gasoline, consumption rates are approximately double, and these carburetors have been modified by Quick Fuel to reflect that requirement.

Monster Poncho power–that’s going to be one heck of a GTO. Click the videos and enjoy the whine!