Our latest shop endeavor has us turning our attention to Project MaxStreet. For those unfamiliar with MaxStreet, this 1966 Chevy II came to us in largely stock form, but it didn’t take long for us to dig into this tired Nova to make it into something special. It’s now sporting Detroit Speed mini-tubs, Mickey Thompson drag radials, Chassisworks front suspension with Wilwood brakes, and a burly 555ci Musi/Edelbrock V8 making well over 1000 horsepower. We’re about a week away from firing this bad boy up, but we needed to make sure we had the stopping power before we get this blown big-block moving the car around.

Our latest shop endeavor has us turning our attention to Project MaxStreet. For those unfamiliar with MaxStreet, this 1966 Chevy II came to us in largely stock form, but it didn’t take long for us to dig into this tired Nova to make it into something special. It’s now sporting Detroit Speed mini-tubs, Mickey Thompson drag radials, Chassisworks front suspension with Wilwood brakes, and a burly 555ci Musi/Edelbrock V8 making well over 1000 horsepower. We’re about a week away from firing this bad boy up, but we needed to make sure we had the stopping power before we get this blown big-block moving the car around.

Project MaxStreet has been part of our roster of builds for a while now, but in recent months we’ve turned our attention to this brutal Chevy II to take it to the next level on every front possible. Not only will the custom stainless lines last nearly forever, they’ll look sharp while doing so.

As you can probably assess from this very truncated parts list, we’re pulling out all the stops with MaxStreet – this is going to be one serious machine, and we’re not cutting corners anywhere with this build. Accordingly, we’re upgrading the Chevy’s brake system plumbing with the help of Classic Performance Products (CPP) stainless steel brake lines, braided hoses and clamps. Along with improved durability, these new pieces should enhance the under-car bling so that MaxStreet looks the business from just about any angle.

Building The Lines

Because of the Wilwood brake system and all of our custom modifications to MaxStreet, we needed to make our own brake lines rather than just simply installing a pre-fabricated kit. “Any time you have to make custom brake lines, it’s a bit of challenge,” jokes tech Kyle Kitchen.

Due to the high expense of stainless steel tubing, we used a mild steel filler rod for TIG/gas welding to make the line templates before we started making bends. It’s a very workable material and we needed the templates to be as accurate as possible so we won’t waste stainless steel tubing by making incorrect bends.

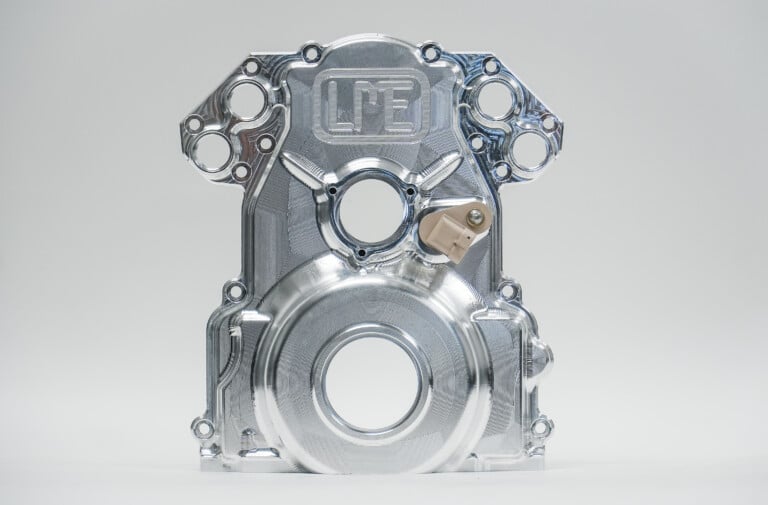

A look at the parts we sourced from Classic Performance Parts for this project. Here we’ve got AN stainless flex line (BHK-SAN), brake hose tabs (BHT), a stainless straight-line fit for GM vehicles (SLS-03), single and double-line clamps (CP316, CP316316), and 3/16 rear flex line kit (RSFLK-316).

“Once a template was completed and we were ready to begin making a line, we would purposely make the tubing a little bit longer than the template so that we wouldn’t come up short and waste tubing,” Kitchen added. “From there we would just cut off the small amount of extra length, if needed, and deburr after test fitting the line before making our double flares.”

When it came time to make a bend using the tube bender, we marked the tubing where the center of the bend should be by using our template. We had to be careful to make sure the radius on the template wasn’t too tight for the stainless steel tubing to match, or we would run the risk of the center point being inaccurate in the bender.

The Eastwood flaring tool (PN. 25304) has a flat die on its rotator that guarantees your brake line will always be perfectly flush in the half dies that hold the line in place. When building the lines we would purposely expose too much tubing on the flare side and use the flat die as a stop gauge before clamping the half dies down tightly.

Once the tubing was flush in the half dies, we started with the proper size “OP 1” die and created a bubble flare. Once the bubble flare was formed, we would then rotate to the “OP.2” die to create the double flare. After that we’d verify the double flare was smooth and clean before installing.

Tricks Of The Trade

Even back east, where the roads are salted during the winter, these lines should last literally hundreds of years. Galvanized steel will last a fraction of that amount of time. If you’re building a nice show car, stainless is what you’re going to want to have. -Javier Nunez, CPP

“Using stainless steel for the hard lines on the ’66 Chevy II made the project a bit more tricky because stainless steel has very limited room for error when bending and flaring before it starts to crack (in comparison to steel or NICOPP lines),” Kitchen explained.

“Because of that, the most challenging part was properly routing the front passenger side brake line over to the proportioning valve on the driver side of the engine bay. There is very limited room between the fender panels and motor, with quite a few components you have to work around, which made creating an accurate template and actually installing the finished product pretty challenging, even with a union to split the line in two pieces.”

We ordered five flexible lines for our project, with one connecting the body to the rearend, and flexible lines at each corner.

Kitchen’s sentiments about working with stainless lines are echoed by Javier Nunez of Classic Performance Products, though both agree that the benefits in aesthetics and vastly enhanced durability are inarguable. “Even back east, where the roads are salted during the winter, these lines should last literally hundreds of years,” Nunez explained. “In comparison, galvanized steel will last a fraction of that amount of time. And of course, if you’re building a nice show car, stainless is what you’re going to want to have.”

In the case of Project MaxStreet we’re building a car that shows just as well as it goes, so adding these sharp looking stainless lines was well worth the extra effort. You can find the parts we used at the CPP website, as well as a host of other components for classic musclecars.

Be sure to follow along with Project MaxStreet’s build process right here.