If you’re fortunate enough to find a complete car for your hot rod project, riding on its original chassis then you’re one of the few (who will probably want a performance upgrade anyway). Whether you plan to build your project with a nostalgic theme, or go with a more modern motif – either way, updating the chassis to something with modern safety and performance is definitely on the top of that “to-do” list for most builds.

The original chassis for many of our favorite rod projects was never intended to withstand the demands that most modern hot rods will place on them. Everything from the horsepower of a modern small-block engine (or something more robust), to the lateral loads placed by handling at speed, and even the weight of modern components and equipment can put a classic chassis at risk for some serious issues.

You could spend hundreds of hours and perhaps thousands of dollars attempting to repurpose and save an out-of-date factory chassis, or you can turn to a company like TCI Engineering, who offer complete, ready-to-build, modern chassis for builders and enthusiasts looking for that perfect performance platform.

These upgraded chassis kits and components incorporate modern materials and design, allowing not only for an easier build, but also for the addition of modern upgrades, as well as the strength and safety required for utilizing modern high-performance components.

TCI builds all of their chassis in house at their Ontario, California facility. Frame jigs such as this one ensure that everything is square and properly lined up before it is welded into place.

Chassis Design

All of the 1928-1940 Ford Street Rod chassis are designed to enhance performance over the original. “No two cars from Henry Ford were the exact same,” says TCI VP and General Manager, Sal Solorzano. In the time the Model A was originally built, Ford had to use multiple sources for frame and body panels to keep up with demand. These were all built to rough dimensions, rather than the more stringent tolerances of today’s cars. As a result, each of these cars often has some uniqueness to it. To get around this TCI used some basic trouble shooting and went with averages. “We looked at five good original chassis and designed our dimensions around the averages from those dimensions,” says Solorzano.

Each TCI chassis is designed utilizing the original profiles, meaning that OEM bodies can be easily installed on their new chassis. They’re designed for use with either car or truck bodies, further expanding the build possibilities.

Chassis Construction

All TCI chassis are constructed here in the USA by trained fabricators at the company’s facility in Ontario, California. Each chassis is built by a team of fabricators and is fully heli-arc, (TIG) welded. All TCI chassis come with a limited lifetime warranty. TIG welding the chassis does take some additional skill and labor, however it also offers the car greater strength and the chassis greater beauty. “You don’t have to worry about grinding down our welds, they’re already beautiful,” says Solorzano.

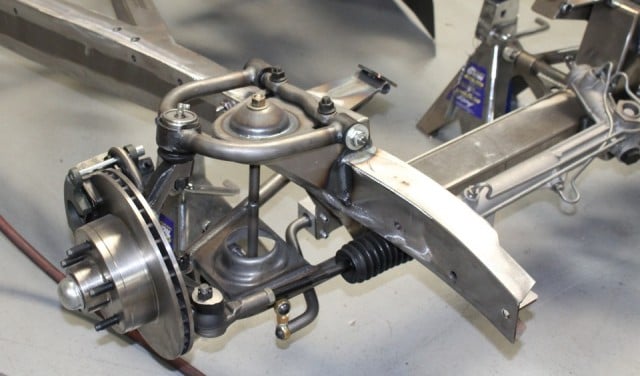

This chassis is mocked up, all of the Ford street rod chassis include the front and rear suspension, rear axle and differential, and brakes. Hundreds of options are available to suit customer preferences and build requirements.

All TCI chassis include fully boxed frame rails that are made of heavy-duty steel, with 0.125-inch thick steel being used for the Model A ’28-31 Chassis, and 10-gauge steel for all the others. According to Solorzano, these frames are about 20 times stronger than the factory originals, “The doors aren’t going to pop open when you pull into your driveway,” he says.

The X-member

Notice the X-member for reinforcing the chassis, while still allowing clearance for 2-1/2-inch exhaust.

On the 1932, ’33-34, and ’35-40 chassis there’s another unique feature from TCI, the X-member. The TCI designed X-member not only improves chassis rigidity and strength over the original, it also is designed for better exhaust clearance and routing.

The X-member is made from 0.75×2-inch rectangular steel tubing. It allows for exhaust diameters of up to 2-1/2 inches to pass through. “The design of the X-member means that the exhaust does not have to pass under the frame,” says Solorzano. This gives increased ground clearance allowing for more ride height options, as well as minimizing worries about scraping or dragging the exhaust.

Testing

In-house testing and R&D is a Total Cost Involved speciality. TCI drives everything they build. Their chassis are put through much more rigorous tests than what the average builder is going to use them for. This ensures quality of both the chassis construction and the engineering work that goes into each and every design.

Options

No two street rods are the same, and with each being an expression of the owner or builder’s style, most buyers will add some options to the cars that suit their preferences for driving, and their individual style. With hundreds of various parts and options the end result is thousands of possible combinations for just one of these chassis, much like ordering a brand new car built-to-suit.

Left: Custom suspension options include TCI Custom IFS, TCI Drop Axle, or TCI Mustang II. Center and Right: These brackets allow for rear ride height adjustment in one-inch increments.

Suspension

TCI builds all of their suspension systems from new parts in-house. One of the biggest choices any street rod builder will have to make is determining which suspension system to use. Customers can choose from airbags, coilovers, drop axles, and even fully independent front and rear systems. “One of the more popular options that customers choose is to go with is stainless steel components for the suspension, such as the A-arms and other components,” says Solorzano. And that is only one of the many options that are available.

TCI’s rear steer Custom IFS is standard on the ’28-31, ’32 and ’33-‘34 chassis. The ’35-’40 chassis comes standard with the Custom Coil Spring front suspension which uses a front mounted rack and pinion. Due to the open fender design, this option is not available for the ’28-31, ’32 or ’33-’34 chassis.

Rear suspensions come as four-link on all ’28-31, ’32, and ’33-34 chassis. The rear suspension on the ’35-40 chassis is standard as a leaf spring. There are various upgrades to all of these including moving the rear frame rails in for more tire clearance, as well as various spring rates, and adjustable shock packages.

There are numerous spring rate and shock package options available for every chassis. This includes coilovers, single and double adjustable shocks, and Ridetech Shockwaves for those looking for air suspension options.

Stopping Power

Another popular option and upgrade is the brake packages. There are varying brake combinations available, everything from standard 11-inch front discs with drums in the rear, to four-wheel discs with rotor sizes up to 13 inches. All brake components are brand new as well, so you won’t be relying on core or remanufactured parts to assemble the car.

Rear Axle

The standard rear axle on all TCI Street Rod chassis is the Currie Enterprises 9-inch. This is a brand new housing, with all new components installed. “The rear axle comes assembled for easy installation and quality control, and it carries a 60,000 mile warranty,” says Solorzano. Axles come standard as 31-spline, 1541 forged pieces. Upgrades to as much as a 35-spline, 1,000+ hp capable differential and axle combinations are available. Customers can also opt for Currie Fab 9 housings, as well as a variety of different posi differentials best suited for their horsepower plans.

Left: New Currie Sportsman 9-inch rear housings are standard with each chassis. Right: For an additional cost, the Currie F9, fabricated rearend housing is available.

Easily Assembled By Customers

Ease of use is definitely a motto we try to design and build by. -Sal Solorzano

“I’ve assembled the ’32 chassis so many times I could probably do it in about four hours on my home garage floor,” says Solorzano. The idea is that customers can easily get a rolling chassis ready in their garage, and mock up the body in as little as a weekend.

Buying A Chassis

We’ve assembled a buyers guide to explain some of the options available for the various offerings from TCI for their most popular 1928-1940 Ford chassis. The list of standard features is quite impressive, and as we’ve mentioned the possibilities are endless for what can be customized to suit specific build parameters.

Depending on the time of year you order, it can take anywhere from 6-12 weeks for a chassis to be built and shipped. Peak order times tend to be the winter months, since this is typically the build season. Summer and early fall orders typically take less time to process and build, since there is less of a backlog.

Completed chassis are shipped on a palette with the front and rearend components shipped separately.

1928-1931 Chassis

Part number 101-1215-00 is designed for the staple of hot rodding, the Model A. Constructed from 2x4x.125-inch tubing, the fully boxed frame of this chassis offers strength that can not be matched with a modified stock chassis. In addition to the standard features we’ve already mentioned, the ’28-’31 chassis also includes the body and hood latches and brackets.

The ’28-31 chassis has a 115-inch frame that is 43 inches wide with a 103.5-inch wheelbase and a 56-inch flange to flange axle width.

TCI custom IFS front suspension comes standard on this chassis and features a reinforced 3/16-inch thick cross member with one piece lower control arm pin design. It also has a 3/4-inch anti roll bar. It comes standard with 11-inch disc brakes with big bore calipers, as well as manual rack and pinion steering. Billet coil overs, DOM upper control arms, and greaseable ball joints round out this component. For a more traditional look TCI offers a Dropped Axle front suspension option at no extra cost.

Before any added options the standard 1928-31 chassis currently shows an MSRP of $7,816.

1932 Chassis

This icon of rodding gets even better with the use a TCI chassis. Just like the ’28-31 chassis, the ’32 chassis, part number: 102-1220-00 features a fully boxed frame. TCI also adds their custom X-member to this frame.

The ’32 chassis comes with front suspension that utilizes front four links. The ’32 chassis is also available with either the Custom IFS or Dropped Axle front suspension. Customers can opt to step up to the coilover Custom IFS that is standard on the ’28-’31 chassis for better handling, this is an additional cost option on the ’32 chassis.

Customers buying a ’32 chassis will also get the front and rear spreader bars. The frames on these can be pinched for a Model A body, and the rear can also be bobbed. Stretching the frame an additional three inches is also an option. You can also opt for a stock or a flat floor setup when ordering this chassis. The standard ’32 Ford chassis before any options is currently listed at $9,505.

1933-34 Chassis

The ’33-34 chassis utilizes a frame measuring 151 inches with a wheel base of 112 inches. Just like the ’32, this chassis features an X-member to both brace the frame, and allow for adequate exhaust clearance. The ’33-34 chassis is also available with either the Custom IFS or Dropped Axle front suspension. Flat or stock style floor setup is available with this chassis as well. This chassis, part number 103-1225-00 before any additional options carries a price tag of $9,505 just like the ’32 chassis.

1935-1940 Chassis

Part number 104-1235-00, is the ’35-40 chassis. With a leaf spring rear axle, and Custom Coil Spring front suspension standard, the ’35-40 chassis promises great ride and handling characteristics. Additional leaf springs are available for the rear suspension to accommodate woody weight characterstics. The front suspension can be upgraded to the Custom IFS, along with many rear suspension upgrades, further increasing the available options. The ’35-40 chassis has a 157-inch frame with a 112-inch wheel base, with a width of 49 inches and is currently listed at $8,982 before optional upgrades.

1935-1940 Chassis

Painted, Coated, or Bare

TCI offers the option of having a chassis painted or coated before it’s sent to the customer. Ordering this option though is something that needs to be pursued with caution. The mock up process may require any number of changes on the customer end to get the final fit they’re looking for. Scratches, and marks from adding additional parts and pieces during the mock up process will have to be repaired if a chassis is ordered already painted or coated. TCI generally recommends that customers order the chassis bare, proceed with their mock up, and then have everything painted or coated. This can save time, hassle, and frustration, as well as money spent on repairing damaged finish on the frame.

- Fully boxed frame with center section and all cross members installed

- Stainless braided brake hoses

- Small-block engine brackets mounted

- Automatic transmission crossmember mounted

- Frames are specifically built for the intended model year cars or trucks

- Stainless eccentrics used in upper control arm mounts making proper alignment easier

- Large vented rotors and calipers for improved braking performance

- Suspension system designed to increase the comfort and drivability of the car

- Large anti-sway bar

- Heavy duty upper and lower screw-in ball joints

- Suspension geometry designed to keep the tires flat on the ground, improving grip, tire wear and cornering

- Anti-dive design keeps the tires flat on the pavement under aggressive braking, improving stopping distances

- Energy Suspension polyurethane bushings used throughout suspension

- New 9-inch Currie Sportsman housing with customer choice of gear set (3.00 – 4.56)

- New differential case with 3.062 inch carrier bearings

- 3x.188-inch wall axle tubes made from D.O.M. tubing, capable of withstanding high horsepower applications

- Billet steel 9-Plus bearing ends for strength

- 31-spline forged induction heat-treated 1541 alloy axles rated for up to 600 hp

- Wheel studs available in half inch or 7/16-inch diameter

- Wheel bolt patterns 4.5-inch or 4.75-inch available

- 1330 driveshaft yoke is common to most driveshaft builders and should make sourcing a drive shaft easier

Standard Features Unique To Specific Years

- ’28-31 chassis includes body and hood mounts and latches.

- ’28-34 chassis includes 4-link rear suspension with adjustable equal length performance 4-link bars, to help eliminate wheel hop under aggressive acceleration

- ’28-34 Chassis include axle brackets that can adjust ride height in one inch increments, with three settings available

- ’28-32 chassis come in 56-inch axle flange to axle flange widths, with optional widths available

- ’32-34 chassis include front and rear spreader bars

- ’32-40 chassis have a rectangular X-member for additional strength, designed to allow exhaust systems to easily pass through

- ’33-40 chassis come in 56-inch axle flange to axle flange widths with drum brakes, 58-inch with disc brakes and custom widths are optional

The design of the X-member means that the exhaust does not have to pass under the frame. -Sal Solorzano

- Stainless steel brake lines

- Engine mounts other than standard small-block mounts

- Cross member and pedal assembly for manual transmission

- Narrowed frame rails for wider “Pro Street” wheels and tires

- Show package

- Zinc coated, drilled, and slotted brake rotors

- Drop spindles

- Power rack & pinion steering

- Polished front billet rebound adjustable coilovers

- Plain or polished front billet rebound & compression adjustable coilovers

- Powdercoated control arms (black)

- Chrome springs

- Wilwood 11-, 12- or 13-inch brakes

- Rear GM caliper disc brake kit

- T.S.D. (Torque Sensing Differential) – clutch type differential rated for up to 400 hp

- Tru-Trac gear type differential, rated up to 600 hp

- 0.25-inch stainless steel air lines and fittings

- 35-spline axles

- Currie F9, fabricated 9-inch axle housing

- Platinum-Trac differential, available only in 35-spline rated for 1000+ hp

- Billet pinion support

- Billet yoke

- Aluminum third member housing

- Aluminum housing available in plain or polished finish

- Kugel independent rear suspension

- Frame rails lengthened up to three inches

- Frame rails detailed before assembly

- Raise IFS crossmember and c-notch frame rails for rack clearance for an additional ride height drop

- Change bolt pattern from 4.5-inch to 4.75-inch

Currie 9-inch center sections just waiting to be added to a package as an available option along with other goodies. Right: An empty 9-inch axle housing before assembly. All rear axle assemblies are shipped ready to install, even the gear oil is included.

Options Unique To Specific Chassis

- ’28-34 chassis, Ridetech Shockwave front and rear airbags available

- ’32 chassis, pinch front frame heads to match ’28-29 Model-A body

- ’32-34 chassis, bob rear frame rails

- ’32-40 chassis, raise rear crossmember one-inch for an additional drop in ride height

’35-40 Chassis Options

- Heavy duty add-a-leaf for woody builds

- 4-link rear suspension

- Double convoluted front and tapered air bags rear

We’ll be headed over to TCI to follow the buildup of a complete ’36 Ford chassis in the coming weeks for our upcoming Rod Authority project build. We’ll be bringing you the inside scoop on how a chassis is built and assembled and follow along the stringent quality control process that TCI is known for – where industry “standard” just doesn’t cut it!

We’ve listed as many options and standard equipment as possible with this guide, however there are unlimited options and possibilities based off your specific build and needs. With the countless options, high quality materials, and a ton of improvements and upgrades over the original, a TCI chassis is a sound choice for any street rod project. Make sure to check out their new updated website or call one of their helpful tech experts to get started building your dream setup for your next build – as we all know, every great build starts with the right foundation.