[1]There are two traits about Mopar K-members that most Mopar owners are aware of. First, they were fine when they rolled off the assembly line, but the strength is just not there if you want to bolt some serious power to it – they need to be reinforced in certain areas, and there are even kits to perform this task.

[1]There are two traits about Mopar K-members that most Mopar owners are aware of. First, they were fine when they rolled off the assembly line, but the strength is just not there if you want to bolt some serious power to it – they need to be reinforced in certain areas, and there are even kits to perform this task.

The second trait is that they’re almost like snowflakes – no two of them are exactly alike. They came out of the factory in the 1960s through early 1980s, and the running joke is that if your car was built on a Friday, you never know what you might get. We bolted a steering box to four K-members and it fit all four a little differently.

[2]

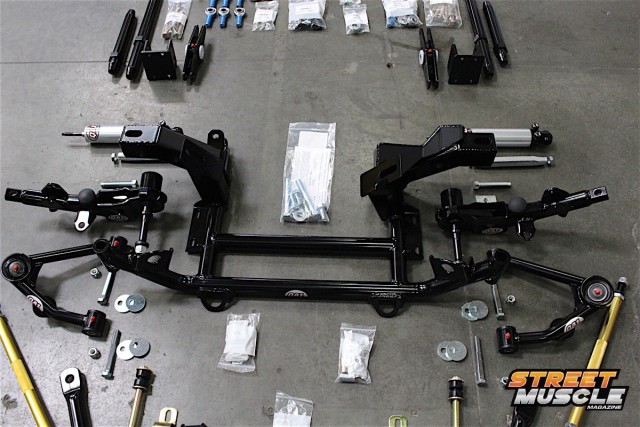

[2]The QA1 suspension kits are available in stages, and with each level the components can increase to include multi-adjustable shocks and QA1 ball joints to replace the OE style. For this Dodge Dart, the kit was 100 percent bolt in, meaning no cutting or welding was needed for any component.

A solution to these two dilemmas is to call up the folks over at QA1 [3] and check into a tubular Mopar K-member for your A-, B-, or E-body car. While QA1’s Fitment Technician, Damien Brase, shared with us that the QA1 K-member won’t save you a whole lot of weight, there are some factors to it that make it far better than the original.

The QA1 unit is tubular, and that makes it stronger than the original, stamped steel unit. There is far more torsional strength, and because it’s tubular it offers more clearance room for headers than the original unit. The QA1 K-member is not as bulky as the factory unit, so it opens up some area beneath and around the engine, and just looks better in the car than the original.

Both upper and lower control arms are tubular, providing additional strength over the stamped steel OE arms.

Other factors that make this a better choice for Mopar owners are that it’s a direct, bolt-in unit that requires zero modifications. It will work with either the factory suspension and steering components, as well as factory engine mounts, or for those stepping up their game and upgrading all around, like we did, QA1’s tubular control arms and dynamic strut rods are also a direct replacement and will work with the tubular or factory K-member.

Additionally, for those who step into other aftermarket parts, like Borgeson [7]‘s Mopar steering box, TTI [8] headers, and Schumacher [9] engine mounts, you’re not going to run into any problems with the QA1 K-member either, because it’s a direct replacement and accepts any component that fits the factory K-member.

[10]

[10]Starting with a fresh build, the suspension was the first to get installed so that the car can be moved around more easily. Future coverage will include a full feature article, as well as driving impressions at a local racetrack.

Viau Motorsports’ 1967 Dart Project Car

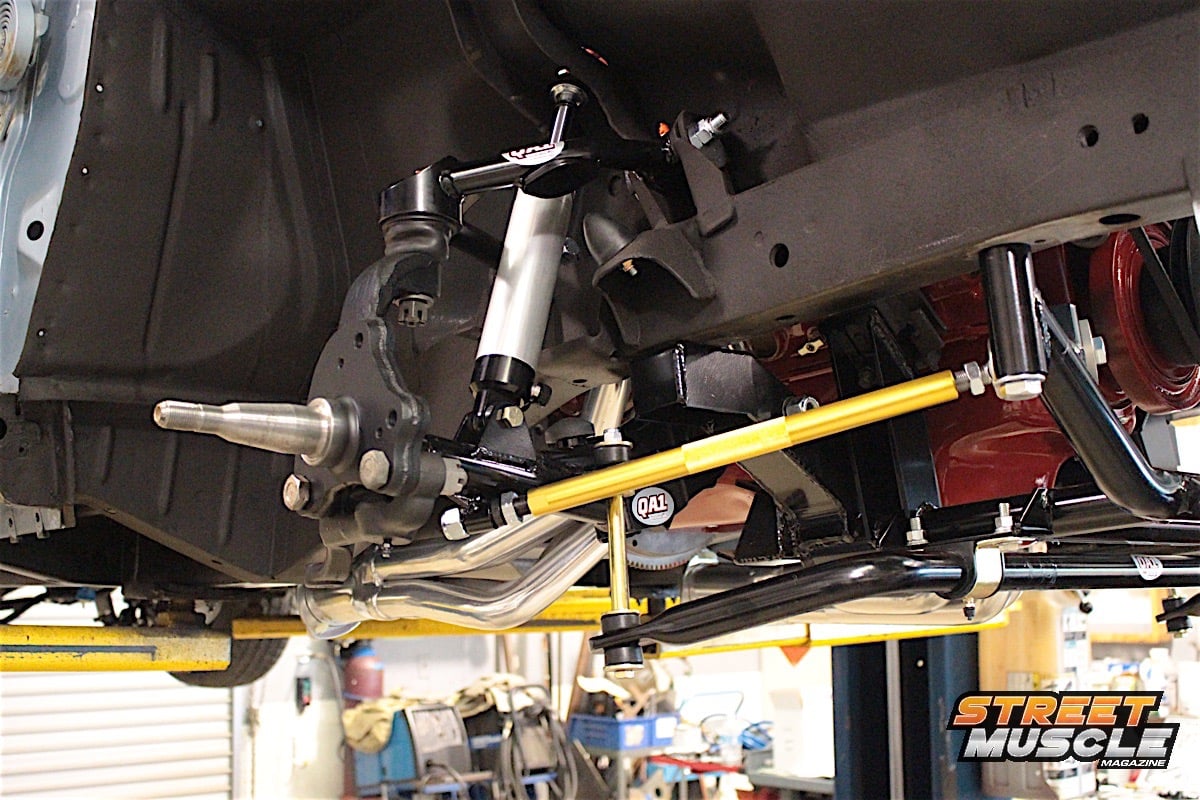

We recently installed the new six-link rear suspension [11] in this fresh build at Viau Motorsports [12]. The car went into the shop where technician Aaron Bourdage stripped everything out of the car for a full restoration. But somewhere along the lines, the goal changed to a restomod with some autocross and road racing capability thrown in for fun.

[13]

[13]Everything that could be unbolted was removed from the front suspension, but nothing was cut or removed from the factory welded supports because QA1 components are designed to replace the factory parts.

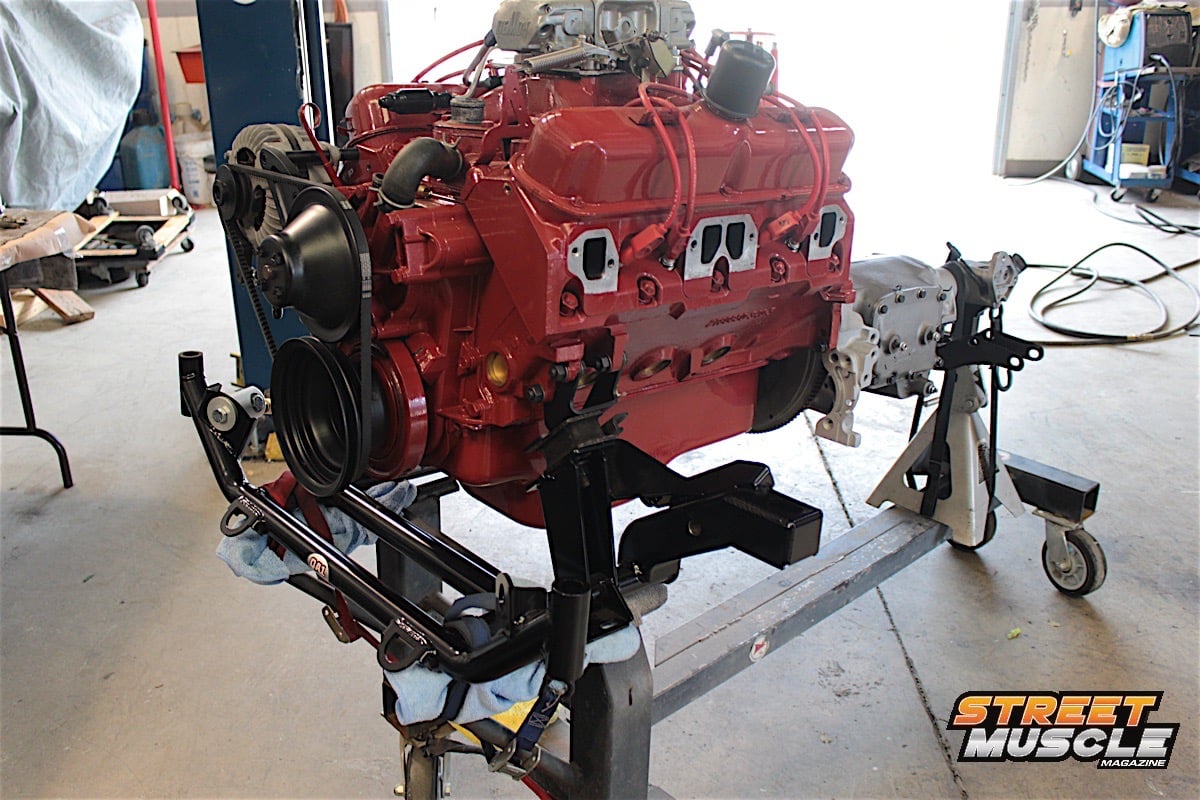

After the rear suspension was installed, Bourdage went to work on the front suspension. With a freshly built small-block and a four-speed transmission to change the gears, the car is going to be a fun driver with a little bit of potential to shake things up once in a while.

The QA1 front suspension, since it’s an OE-style upgrade, still utilizes the torsion bars from the original Dart, which are being upgraded. However, getting away from the torsion bars means a complete new suspension, and the goal of this car was to keep everything to a bolt-in upgrade without any cutting or welding.

Top: Because this is a complete, fresh build, some tasks were easier using a custom-built engine stand to hold the engine and K-member.

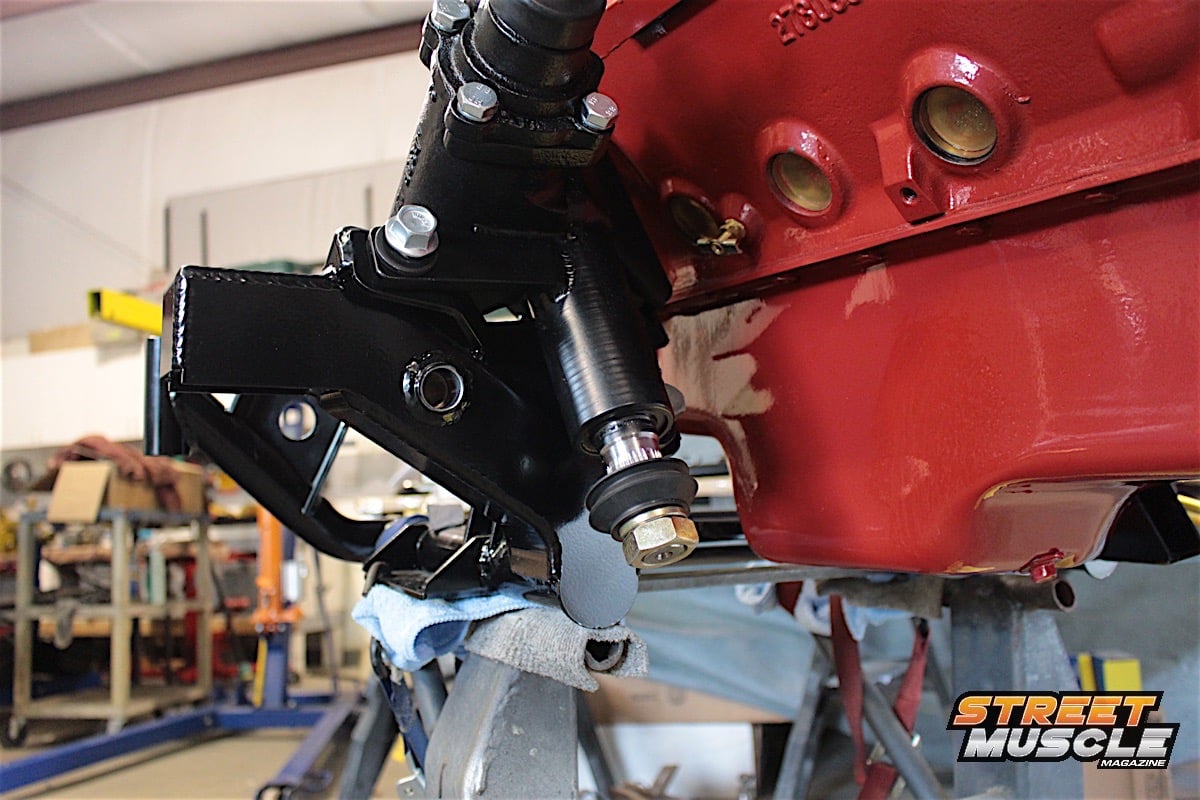

The lower control arm is tubular, and the strut link is aluminum, removing a few pounds from each side.

That’s where the QA1 K-member shines: it allows stock or upgraded components as a direct bolt in. That means you can install the stock arms, or upgrade to the QA1 lower control arms with the same K-member.

The lower control arm is also a direct replacement, with provisions for adding the sway bar drop links. It’s structurally stronger than the factory unit, made from 1020 DOM tubing; it’s a couple of pounds lighter and CNC laser cut for accuracy. The pivot pin nut should be torqued to 145 ft-lbs, same as the factory specs.

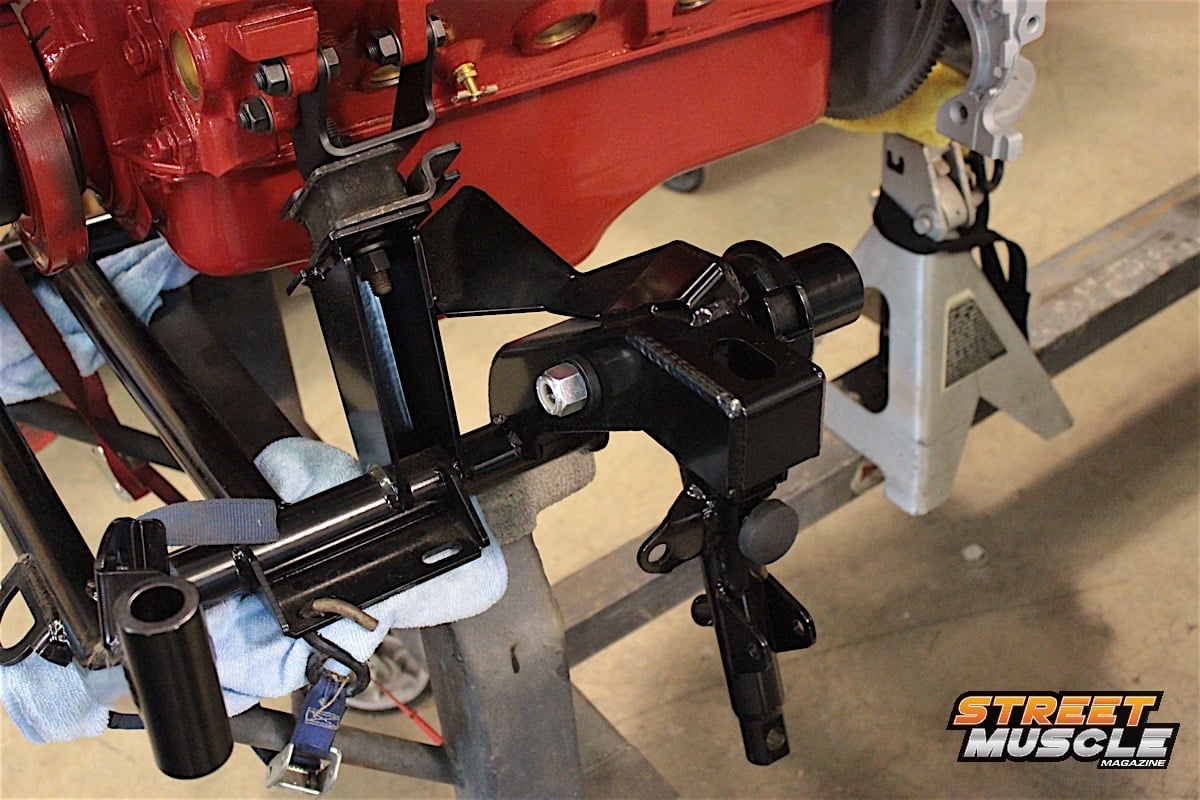

The addition of QA1’s Dynamic Strut Links provides better adjustment of the lower control arm to assure there is no binding on the control arm pivot shaft. The factory strut rod is mounted to the K-member with a pair of rubber bushings that flex and lose their shape over time. As they pivot, they change the dynamics of the sweep of the lower control arm and need to be adjusted as the bushings begin to lose their shape.

[19]

[19]It should be pointed out that the adjustment portion of the Dynamic Strut Link is to help align the lower control arm and keep it from binding on the pivot pin. The links are not designed to make any adjustments to the suspension.

The Dynamic Strut Links mount with a fixed aluminum bracket and maintenance-free rod ends. Regardless of how old they get or how many times the suspension is articulated, the QA1 links return the lower control arm to the same spot at rest every time – because there are no wearing parts in the Dynamic Strut Link.

[20]

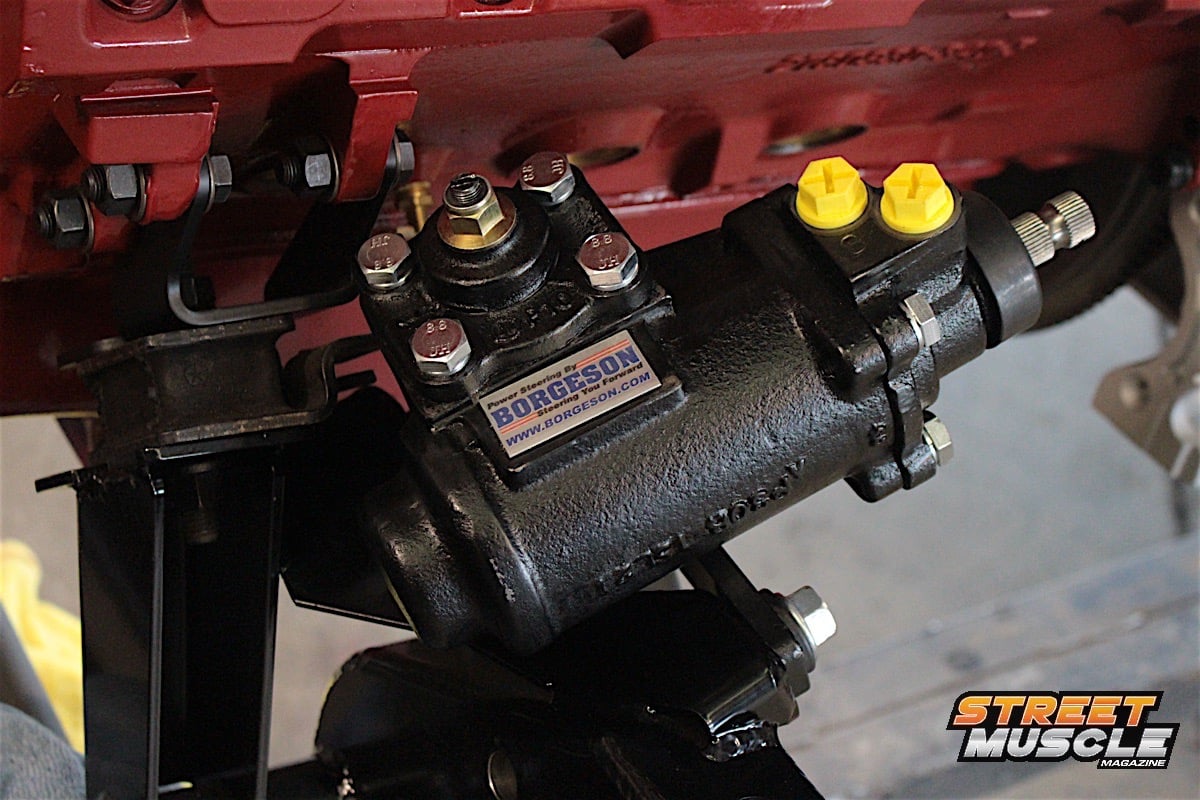

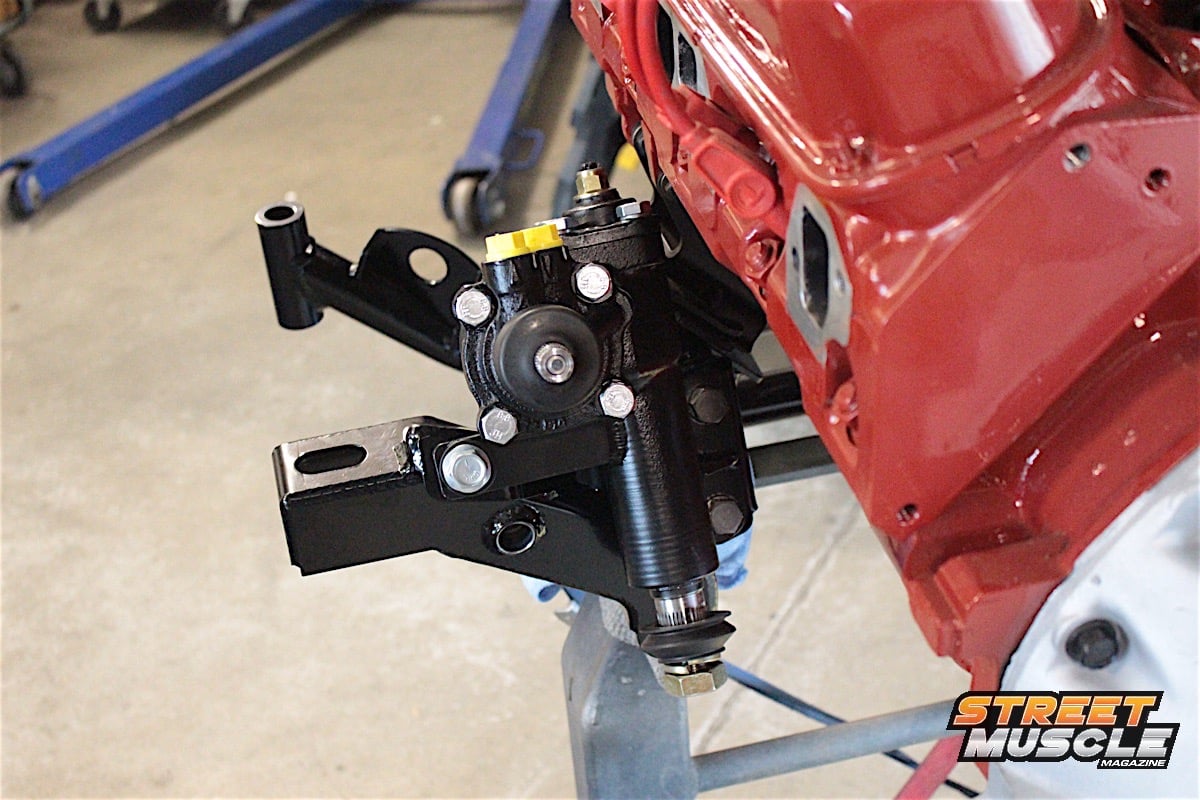

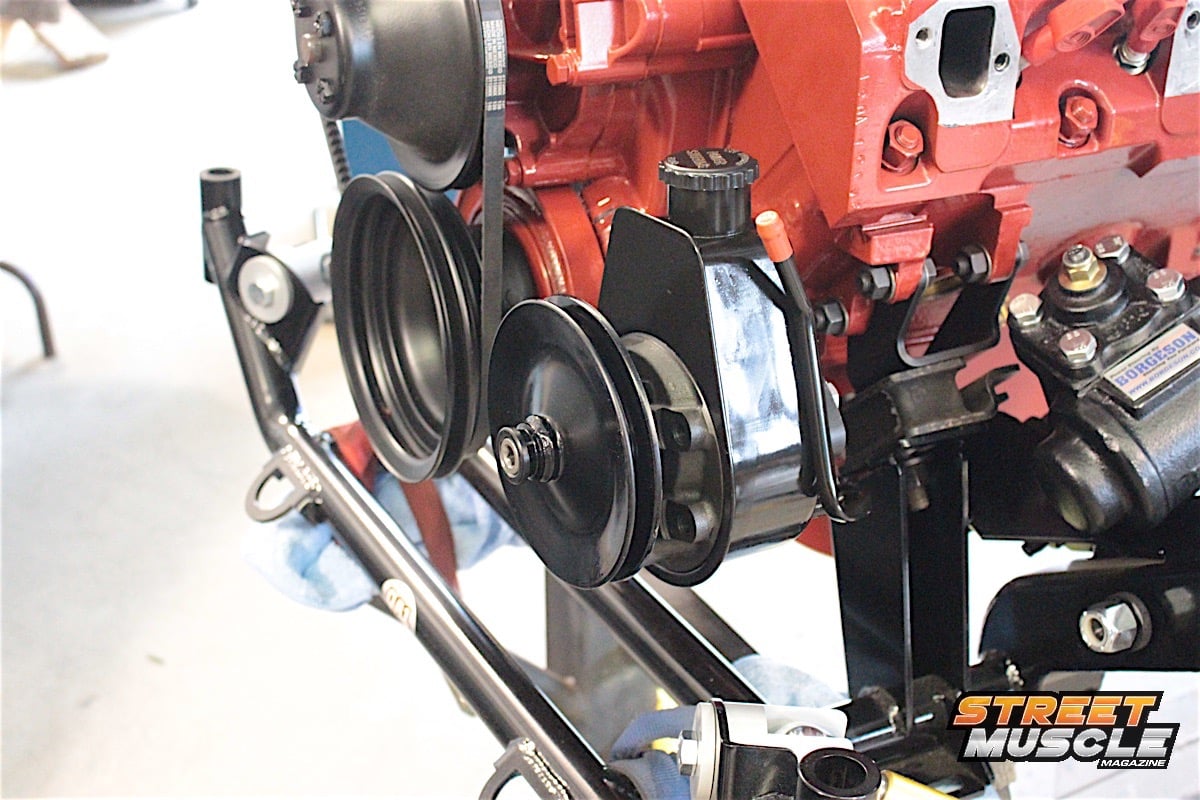

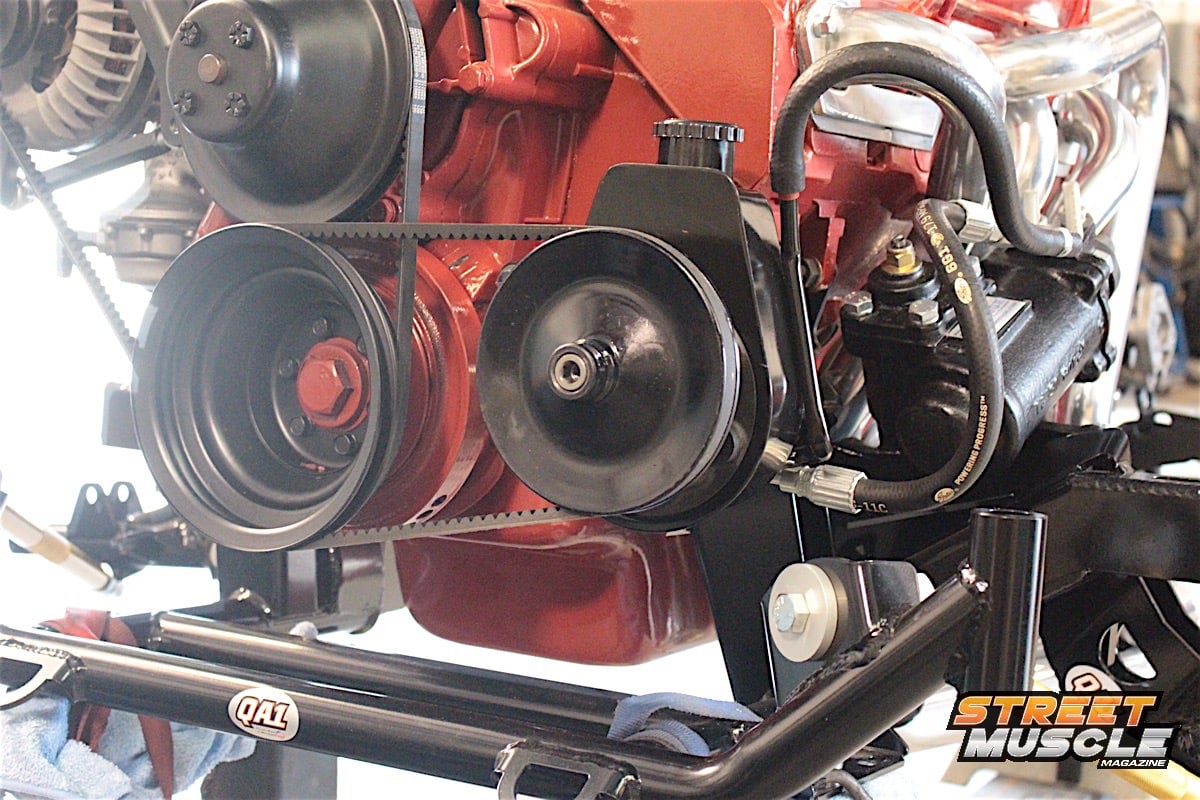

[20]If you’re familiar with the mass of a Mopar power steering box, you’re probably not sure where this anemic looking box came from. It’s small and light, but packs a mighty punch, and comes from Borgeson Universal.

Bolt-In Steering Upgrade

With this upgrade, we decided to make some improvements to the steering as well. With the original box being old and worn, it was not a simple replacement. It required a rebuild which doesn’t improve steering feel and is still prone to the same issues that plague older steering box technology. The solution from Borgeson Universal [7] not only saves about 13 pounds, but improves steering feedback and response.

Borgeson acquires brand new steering boxes and re-splines them for 1962-1982 Mopar vehicles with either the 1-1/8-inch or the 1-1/4-inch pitman shaft. By using a new box built to today’s standards, days of lane-wandering every time you look over your shoulder are gone. The new box provides a firmer feel and a quicker, 14:1 ratio, and does away with 50-year-old technology that ends up in rebuilt Mopar steering boxes.

The Borgeson steering box upgrade for classic Mopars is a popular choice when car owners want a better feel and quicker turning ratio.

Borgeson modifies the box to bolt into a factory K-member, which means the fitment into the QA1 K-member is not a problem. The box is considerably smaller than the factory box, making room for headers and exhaust.

The steering box includes the proper fittings for the factory-style high- and low-pressure lines, and includes a universal joint and instructions for mating to the factory steering column shaft. For those who prefer the older style coupler, an extended coupler can be acquired from Bergman Auto Craft [25] without any cutting of the factory steering shaft.

In addition to a better performing steering box, Borgeson also has brand new Saginaw steering pumps and its own mounting bracket.

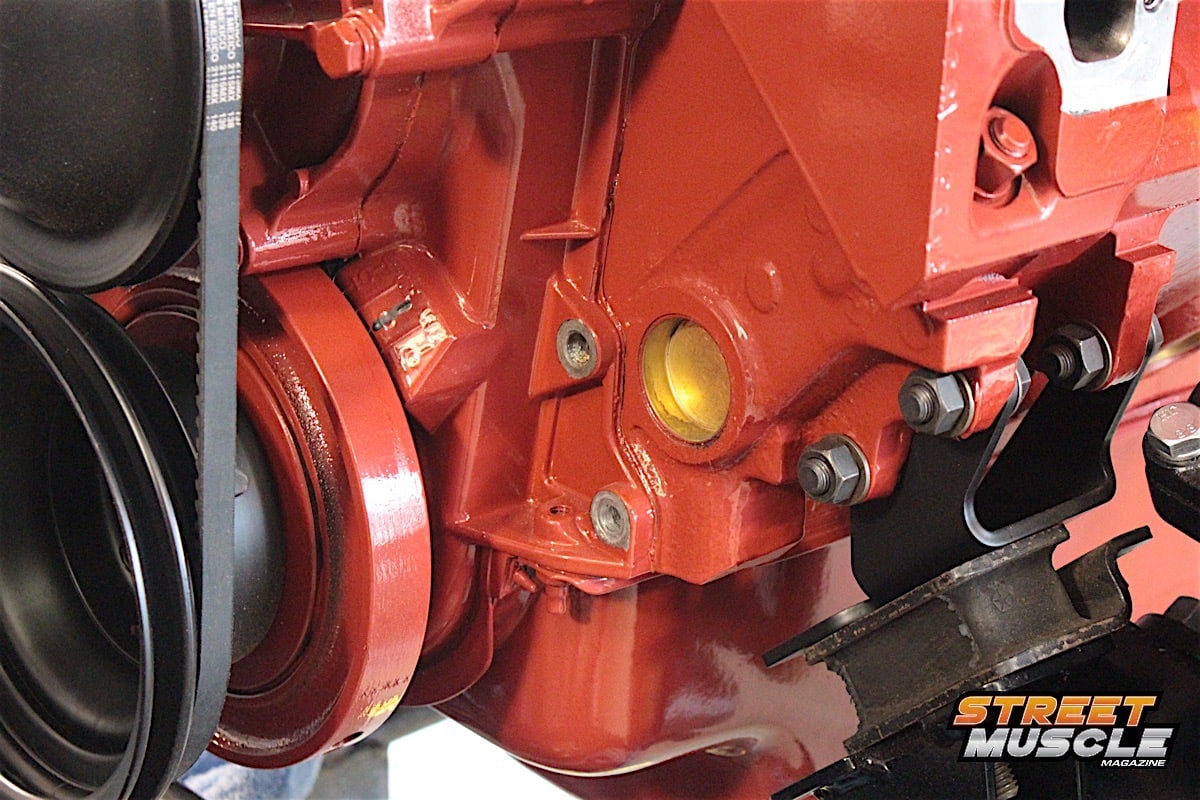

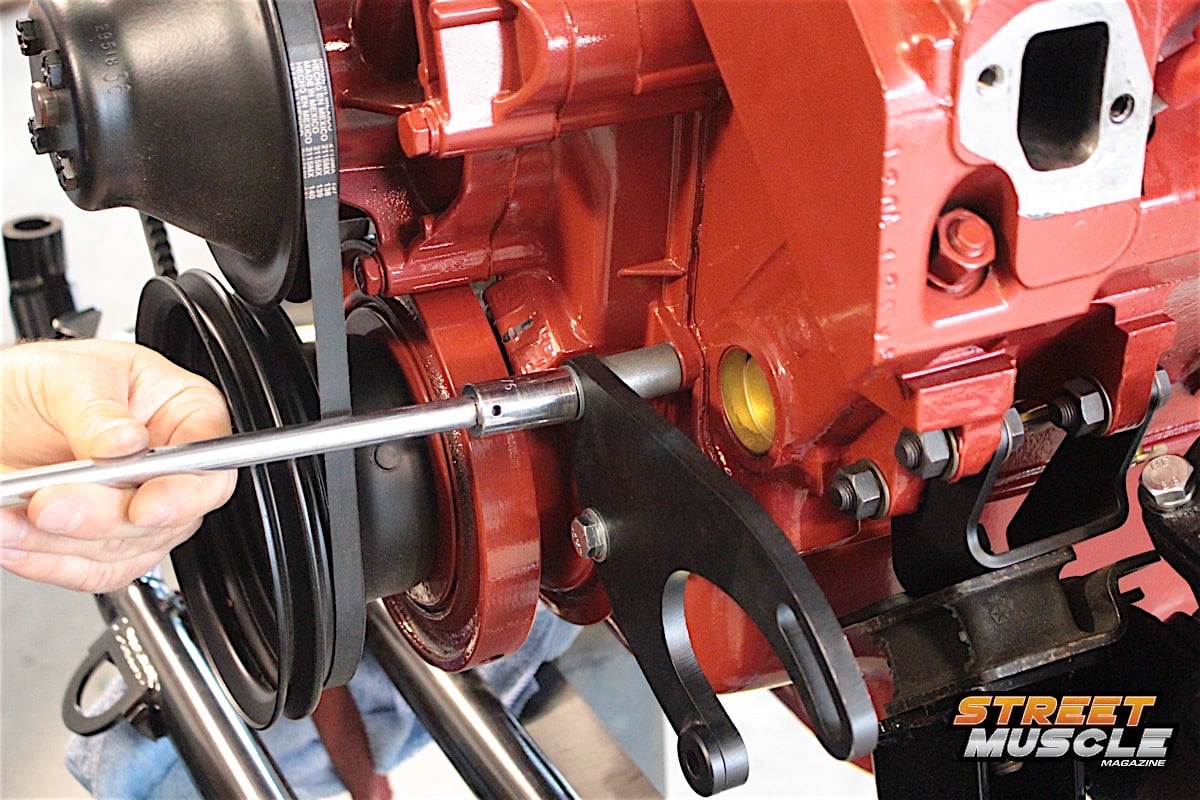

In addition to the steering box, we installed the Borgeson small-block Mopar steering pump kit. Gone are the days of searching wrecking yards to find the right brackets for your steering pump upgrade from the early Thompson to the Saginaw, because Borgeson’s pump kit includes a new Saginaw pump and Borgeson’s own mounting bracket for small-block (LA) Mopar engines.

Borgeson’s Jeff Grantmeyer said, “That’s the beauty of having our own in house manufacturing equipment. We can take an existing setup and with our waterjet we can cut new brackets to our specifications and put them into production.”

Whether you're upgrading your existing power steering or converting to power from manual, you'll find everything you need to complete the upgrade, with exception of the drive belt.

Instead of multiple brackets that mount to varying front cover/water pump designs, the Borgeson kit bolts directly to the block for mid-1970 and up LA engines with the water pump outlet on the passenger side. The kit also includes both the high-pressure and return lines for the steering gear, making this a complete power conversion kit, as well.

[35]Bolting In The Engine/Trans Assembly

[35]Bolting In The Engine/Trans Assembly

With the engine and transmission bolted together and mounted to the QA1 K-member, the entire assembly can be lined up under the car when raised on a lift. While a lift is not a requirement for this installation, it does allow for the car to be lowered onto the engine/K-member assembly for easier installation.

Being careful to line things up as the car is lowered over the engine and transmission, the K-member can then be bolted to the front subframe of the Dart. Since Viau Motorsports does restorations and custom builds of classic Mopars, having additional equipment – like this engine stand built specifically for this task – made the installation a little easier.

Upper control arm installation is a direct replacement for the factory control arm, and bolts in with the factory camber bolts or QA1's kit. Shocks are double adjustable, and the factory torsion bars are retained as this apron is not designed to support the weight of the car, so coilover shocks are not available from QA1 for this application.

The advantage of upgrading to QA1 control arms is that while they can utilize the factory camber bolts and mount in the factory locations, the added three degrees of caster built into the upper arms, and an adjustment range of -2.5 to +2.5 degrees of camber, allow for better handling. QA1 also supplied us with its own camber bolt kit; though the kit is a direct replacement, this was the right time to install new bolts over the 40-year-old parts.

With the new K-member bolted into place and the upper arms installed, the final assembly of the double-adjustable shock absorbers were next, and that tied up the complete front suspension/steering setup. Working with other companies to ensure compatibility between components helps make upgrades like these a simple task because nothing has to be modified during the installation.

All shock adjustments should be made starting at a softer setting and count the clicks up from there. -Damien Brase, QA1

“All shock adjustments should be made starting at a softer setting and count the clicks up from there,” Brase said. “Our guidelines will give a general range to start in, then the user can adjust up or down from there depending on the ride or handling characteristics they are looking for.”

The other important aspect of installing adjustable shocks is to make sure that the adjustment knobs are accessible from under the car while it’s on the ground. We’ve seen where people immediately want to start with a firmer setting, believing that it equates to better handling, but that’s not always the case.

Brase said, “Stiffening the rear shocks and or sway bar can help reduce understeer, as will softening the front shocks.” This is why it’s highly recommended to start softer and keep track of the clicks for each setting. Additionally, keeping the setting consistent from side to side is important as well.

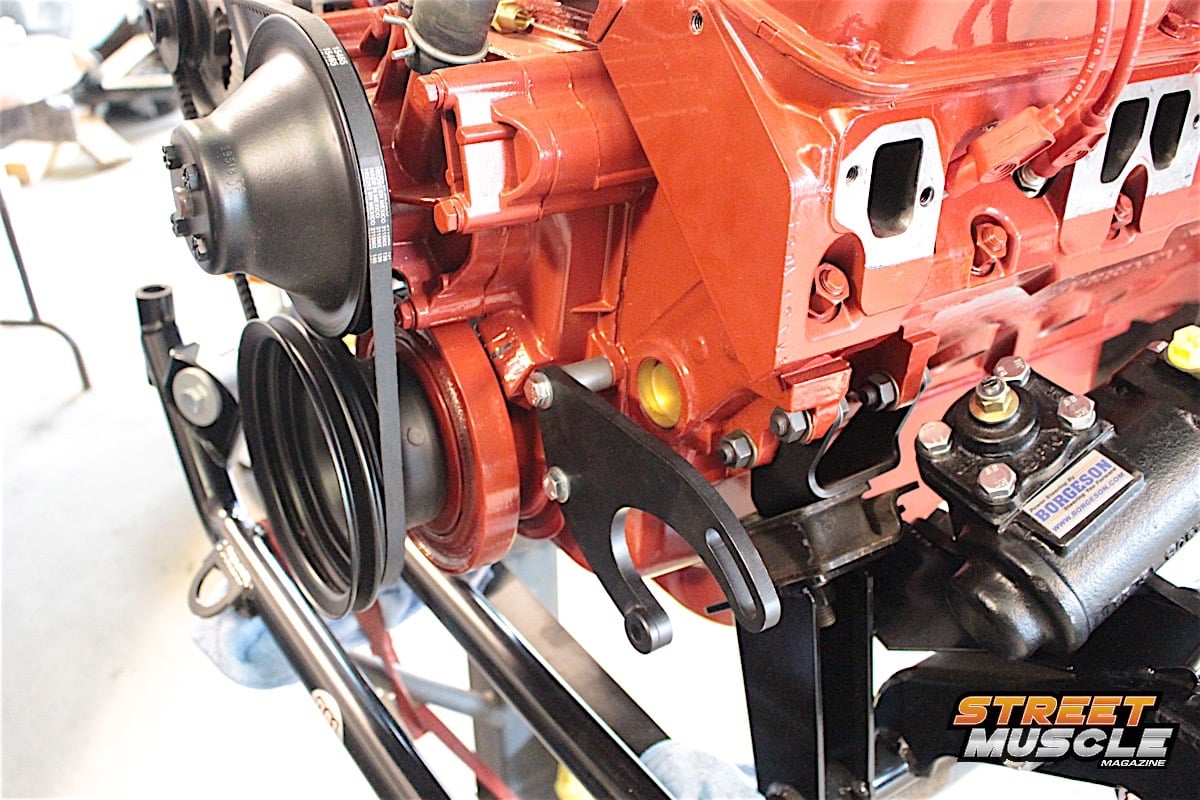

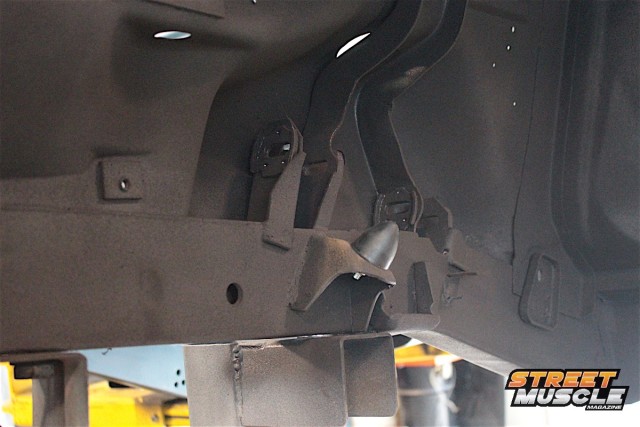

[40]

[40]Mopar owners aren’t used to seeing this much space around a steering box, but with the Borgeson upgrade there’s plenty of extra room.

Now with the additional room underneath thanks to the QA1 K-member and the smaller, lighter Borgeson power steering box, underhood work gets a little easier while the front suspension gets a performance makeover.

We will follow up with a driving test of this 1967 Dodge Dart once the rest of the car is completed and it’s properly broken in. Brase also suggested, “The car should be tested and have the bolts and jam nuts checked for tightness after about 50 miles.” This advice includes the rear suspension previously installed.

In the meantime, if you’re looking to upgrade your Mopar or GM vehicle with a performance suspension kit, give the folks at QA1 [3] a call and let them know what you’re working on. Performance handling kits are available in three stages [41], which allows you to make affordable upgrades over a period of time as opposed to making them all at once.