The 2.3-liter EcoBoost engine represents an all new technology for the Mustang. This engine is making factory horsepower and torque numbers only previously seen in V8 powered GTs and even Cobras just a decade or so ago. With EcoBoost being the darling of the Ford engine family, tuners have rushed to tweak cars like the Fiesta and Focus ST, Taurus SHO, and even the F-150. It’s little surprise that many of the lessons learned from those platforms are now being applied to the Mustang EcoBoost in the quest for more power, and a better driving experience.

The 2.3-liter EcoBoost engine represents an all new technology for the Mustang. This engine is making factory horsepower and torque numbers only previously seen in V8 powered GTs and even Cobras just a decade or so ago. With EcoBoost being the darling of the Ford engine family, tuners have rushed to tweak cars like the Fiesta and Focus ST, Taurus SHO, and even the F-150. It’s little surprise that many of the lessons learned from those platforms are now being applied to the Mustang EcoBoost in the quest for more power, and a better driving experience.

We recently had the opportunity to install and dyno test two of the easiest modifications for the Mustang EcoBoost on our Project 5-Liter Eater. JMS Chip and Performance has been producing EcoBoost products for four years No strangers to the EcoBoost world, JMS sent us its BoostMAX, part number BX-6000-23, and PedalMAX part number PX-5000-1114F, products for Project 5-Liter Eater, so we could conduct dyno and drive testing.

For our install, we headed to London Chassis Dyno to baseline, install, and test out the JMS BoostMAX and PedalMAX parts.

Plug and Play Power

We knew EcoBoost was going to be the wave of the future for Ford products. We use partnerships like the SEMA initiative gain access to early information and to work with preproduction vehicles to develop our products. -Brad Grissom, JMS

We talked with JMS’s Brad Grissom, regarding the company’s experience with the EcoBoost platform, and to get some background on JMS. JMS Chip and Performance has been in business since 1993. This company was one of the first to develop chip tuning in the early 1990s, and manufactured some of the first high performance and custom chips for Mustang processors.

Since that time, JMS has grown, and evolved. Today they still work extensively on factory electronic tuning. They also do some light vehicle assembly in house. Through it all, the company is still focused on electronic tuning, and has a considerable investment in electronics manufacturing.

JMS has been working with the Ford EcoBoost platform since 2011. “We knew EcoBoost was going to be the wave of the future for Ford products. We use partnerships like the SEMA initiative gain access to early information and to work with pre-production vehicles to develop our products” says Grissom.

The BoostMAX (left) and PedalMAX (right), both come with a plug and play harness that fits the OE connectors. There's no splicing, no tapping in, and no cutting wires involved. Connect and go.

BoostMAX

The BoostMAX product is a standalone “on-the-fly” boost control device that connects inline on the EcoBoost engine harness. The unit is plug-and-play with no splices, and no wires to cut. In fact, the unit is powered solely by its connections to the vehicle harness, so you don’t even need to tap into a power supply. BoostMAX works by altering the fuel, timing, and boost strategies via its inline engine harness connections. You can also use the adjustable control knob to dial-in your power increase “on-the-fly”.

We talked with Grissom about how the BoostMAX works. “BoostMAX relies heavily on the OEM electronics, specifically the factory wideband O2 and the knock sensors. The factory electronics can compensate for additional airflow and boost, by as much as 40 percent. BoostMAX capitalizes on the flexibility of the factory control system to increase performance in a safe and effective manner.”

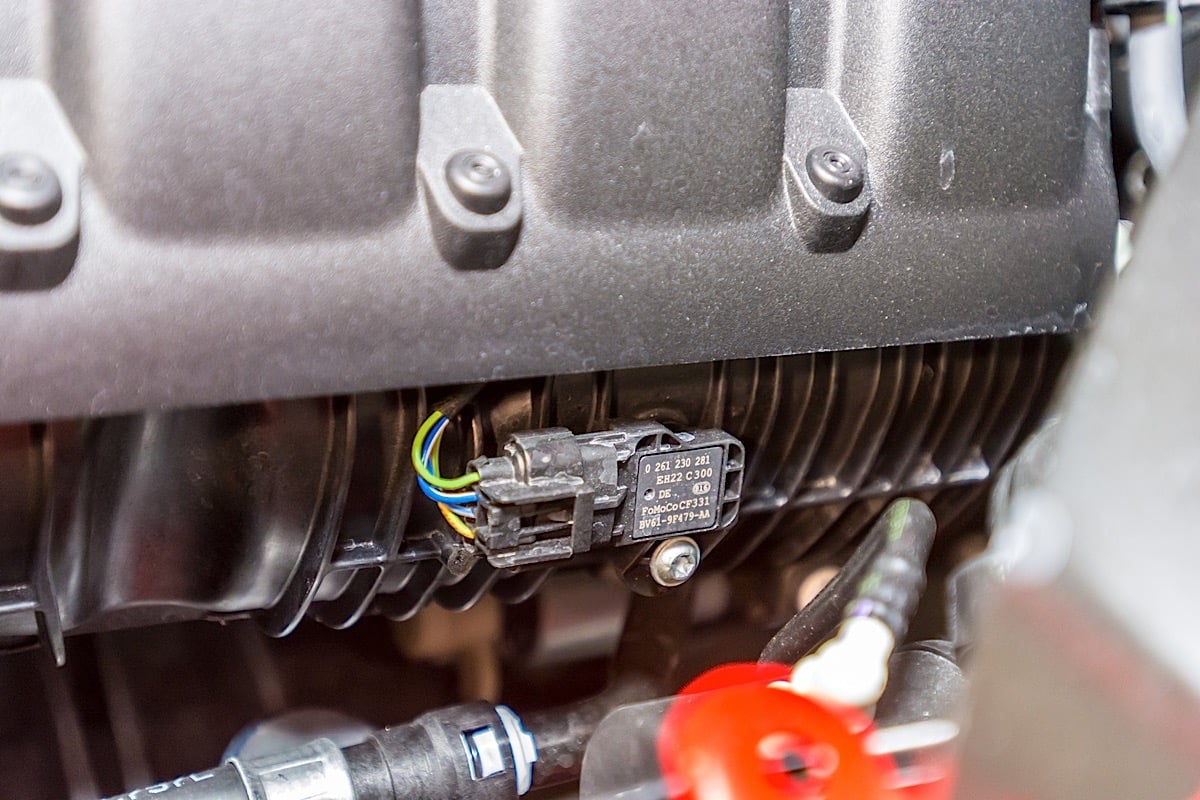

Grissom explained that the factory ECU looks at the MAP (Manifold Pressure), and TIP (Throttle Inlet Pressure) sensors and uses that data to control boost pressure from the turbo. “As we’re adding additional airflow with BoostMAX the factory wideband O2 sensor instantly sees the increase in airflow and the compensates with additional fuel. At the same time the knock sensors are looking for signs of pre-ignition and they instantly adjust ignition timing to match.”

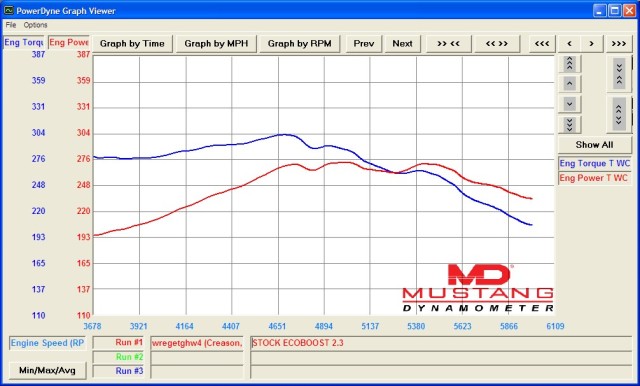

Stock our EcoBoost Mustang dyno’d 273.2 hp and 303.8 lb-ft of torque on the London Chassis Dyno rollers.

“We monitor the accelerator pedal and increase power output in proportion to the throttle input. This technique eliminates part throttle surging that can occur when trying to tune EcoBoost engines.” Grissom also explained that tying the throttle input into the picture allows them to fine tune the power introduction and boost level with the BoostMAX.

PedalMAX

Dial It In

Whether you’re limited to octane selection for your fuel, or you just want more control on either power output, or how aggressive the accelerator pedal is, JMS offers a control knob. They recommend setting it to 50 for lower octane fuels, and 100 for 93 octane (or higher) fuels. The control knob works with either PedalMAX or BoostMAX. The best part is this control knob is infinitely adjustable, so you can literally customize the control.

PedalMAX is designed to provide an all-new throttle pedal strategy for the EcoBoost Mustang. JMS also offers the same product for the S197 and the ’15 Mustang GT. Like BoostMAX, PedalMAX connects inline to the factory harness, and uses a microprocessor to remap the throttle inputs to a more aggressive strategy. “The sole purpose of PedalMAX is to remap the throttle signal. It makes the throttle more aggressive by modifying the factory accelerator pedal signals. With PedalMAX installed, the throttle more accurately follows your foot position and, you have more of a connection between what you’re doing with your foot and how the throttle is responding” says Grissom.

PedalMax requires only a few connections to get it up and running. Tapping into the pedal sensor, and connecting the PedalMAX control unit.

Joining Forces

Under the hood there are only two connections to make for the BoostMAX. The first step in all of this is to disconnect the negative battery cable. The first connection, is the TIP sensor, located on the driver side of the intercooler. This requires removing the engine cover that attaches to the front bumper/fascia. The harness can be routed up and behind the air box to keep it out of the way and away from heat. The second connection under the hood is the MAP sensor, located on the intake manifold. From here the harness must be routed through the firewall.

When the two parts are combined you virtually eliminate boost lag, and get a much more powerful, and more responsive engine.

Testing The Parts

The final install step is the pedal sensor. The PedalMAX is connected first, then the BoostMAX plugs into it, and the factory harness connects to the BoostMAX connector.

We’ve outlined our installation in the photos and captions, but we had both the PedalMAX and BoostMax on the car in about 45 minutes. The most difficult part of the installation is getting the BoostMax harness routed through the firewall grommet. Everything else was plug and play. We did the entire installation with he car strapped to the dyno, while it cooled down for before/after pulls.

Prior to our installation, we baselined Project 5-Liter Eater at London Chassis Dyno in London, Kentucky. There, we, were able to spin the rollers to respectable 273.2 hp and 303.8 lb-ft of torque at the rear wheels with the car stock. These are respectable numbers and put us at around 12-percent parasitic loss between the crank and the wheels on horsepower. With torque the loss appears to be less than 12-percent, leading us to think that perhaps the EcoBoost engine torque is a little under rated from Ford.

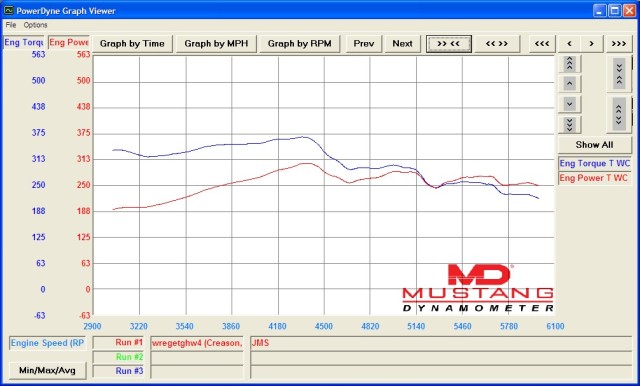

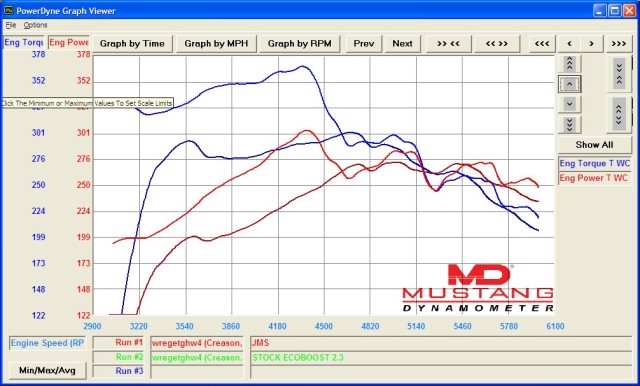

On the dyno we were pleasantly surprised with 306.7 hp, and 370.3 ft-lb torque. A gain of 33.5 hp and 66.5 ft-lb of torque to the rear tires over stock.

Power gains are even more prevalent when we overlay the JMS dyno graph and the stock graph. Look how much torque the engine is making as soon as we hit the pedal, and once boost peaks, it really climbs.

With our engine sufficiently cooled down, we fired the car up, checked that everything was operating properly, and then made another run on the dyno. The JMS parts rewarded our labor with an impressive performance. On the dyno, we could actually hear the 2.3’s tiny Garrett turbo working hard, spooling like a big rig on a hill, and our boost gauge peaked out right at 25 psi, a 5 psi increase over factory.

Final power numbers ended up at 306.7 hp and an impressive 370.3 lb-ft of torque at the rear wheels. That’s a gain of 33.5 hp and 66.5 lb-ft of torque to the rear tires. Assuming a 12-percent power loss through the drivetrain our EcoBoost was making 343.5 hp at the crank and 414.7 lb-ft of torque. That’s better than current Mustang GT levels of torque at the crank, and equal to or better than a 4.6 3-valve 05-10 V8 with a few bolt-ons in terms of power at the wheels..

Suffice it to say, we can think of very little else we could do to our EcoBoost project car to gain this kind of power so quickly. On the street the new-found power, especially all that torque is immediately noticeable. At the top end of second and third gears, we noticed the ESC stopping wheel spin on the rear tires. The gobs of torque, and the responsiveness of the engine are incredible, and while the car was enjoyable before, its ability to induce a smile during a quick spin around the block is even better than ever.