Building an engine to excel – and survive – on the road course is much different than building an engine for the street, or for a vehicle that will be drag-raced. The guys at Livernois Motorsports have gained the experience to make solid, long-lasting road-race engines by working with their vast network of customers on research and development This particular road-race 5.0-liter Ford Coyote engine is a culmination of what they’ve learned. The customer has chosen to remain unnamed, as the competitive advantage is not one that they want to relinquish.

Building an engine to excel – and survive – on the road course is much different than building an engine for the street, or for a vehicle that will be drag-raced. The guys at Livernois Motorsports have gained the experience to make solid, long-lasting road-race engines by working with their vast network of customers on research and development This particular road-race 5.0-liter Ford Coyote engine is a culmination of what they’ve learned. The customer has chosen to remain unnamed, as the competitive advantage is not one that they want to relinquish.

“This customer came to us after blowing up a series of engines. They run approximately 15 races a year. Originally the car had the stock Boss Mustang engine, which blew up after one season, then subsequently had engines built by two other companies that didn’t last either,” says Livernois’ Mike Schropp.

“In the classes where they compete, they were off on power and didn’t have enough to keep up with the other cars – the Corvettes and Porsche 911’s – in the straights. They really wanted to make this Mustang package work, and that’s when they came to us.”

Livernois Motorsports is in a unique position amongst the plethora of aftermarket engine builders. Due to their research and development-based working relationship with Ford Motor Company, they’ve developed a number of machining techniques and proprietary parts for these engines that should serve this customer well.

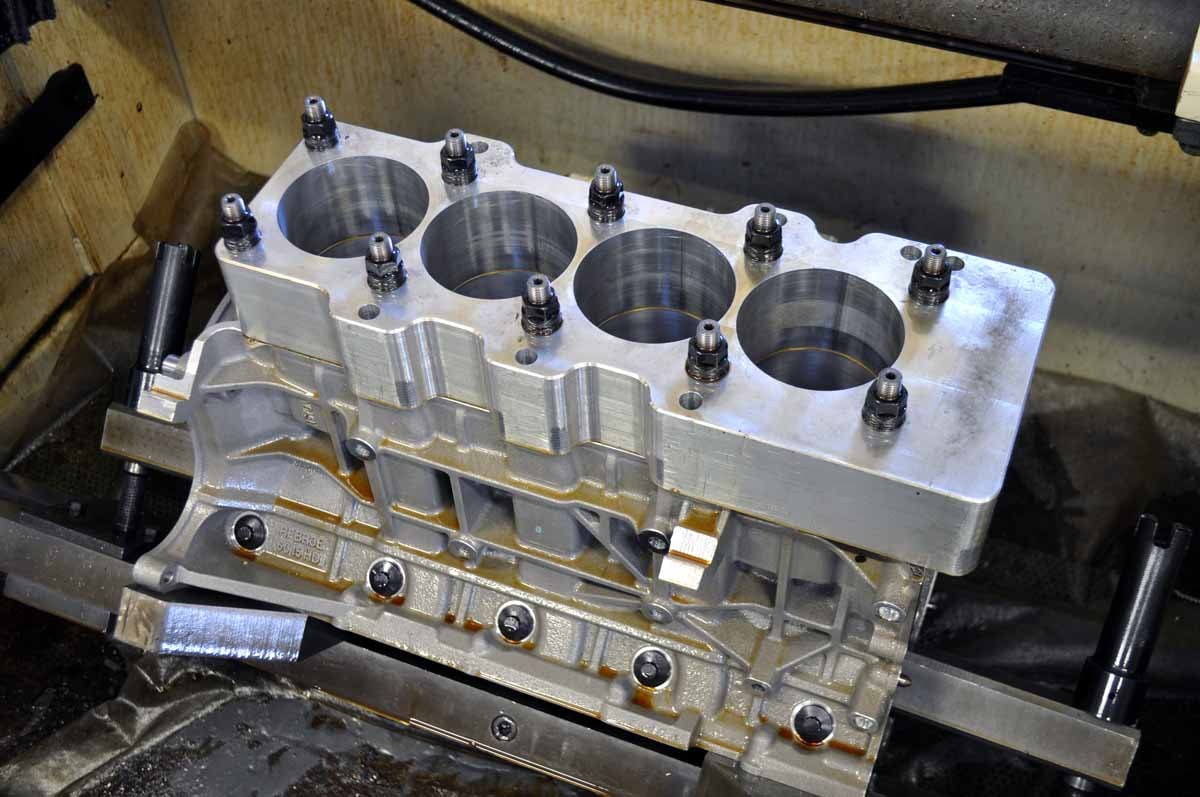

During the block sleeving process, the factory sleeves are machined out and the new, ductile-iron Livernois oversized sleeves are installed. Final bore dimensions are 3.700-inch.

The engine itself is based around a stock block that’s had the factory sleeves knocked out and replaced with Livernois’ proprietary sleeve design, which offers much-improved cylinder bore stability that then translates into improved stability throughout the block.

Unlike modifications performed by other builders to crutch the stock block along, where weld is added to the cylinder/water jacket areas to improve bore stability, Schropp says this is not necessary with their design.

“We’ve found that the factory sleeves that were used in these blocks in 2011 and early 2012 did not have the tensile strength to live under hard use conditions. The sleeves crack, and then the aluminum of the block gives way,” says Schropp. “The factory gray cast-iron material is somewhere around 30,000 psi tensile strength, and our centrifugally-spun ductile iron sleeves have a tensile strength of 120,000 psi – four times the strength.”

With a higher-horsepower combination, Livernois actually refrains from running the maximum bore dimension in order to keep sleeve and block stability in check – with these particular sleeves they’ve seen in excess of 1,500 horsepower. Schropp says that in those applications, the few cubic inches that would be gained by increasing the bore size is not worth the tradeoff in strength.

Livernois’ own rotating assembly consists of a set of coated pistons, forged I-beam connecting rods, coated bearings, and a proprietary ring pack.

The 3.700-inch bore combines with a CNC-modified factory Boss crankshaft that has had the oiling system improved for better flow from the main bearing to the connecting rod bearing. A set of Livernois’ proprietary I-beam forged connecting rods along with a set of Livernois’ own coated custom pistons complete the rotating assembly. Coated bearings are used, along with Livernois’ own main and head studs.

The pistons are built for proprietary 1.2mm/1.2mm/2.8mm low-drag rings and has been developed to be lighter than a Boss piston with greater thickness in all of the important areas. The use of the dome allows for the engine to run higher compression, in this case nearly 13.0:1. The skirt design is offset and has been computer-modeled to allow for the thrust side to be thicker and wider than the anti-thrust side to save even more weight. The underside is strutted in two different directions at the pin boss for improved strength as well, and the light weight allows for maximum acceleration speeds to get the engine up into the powerband more quickly.

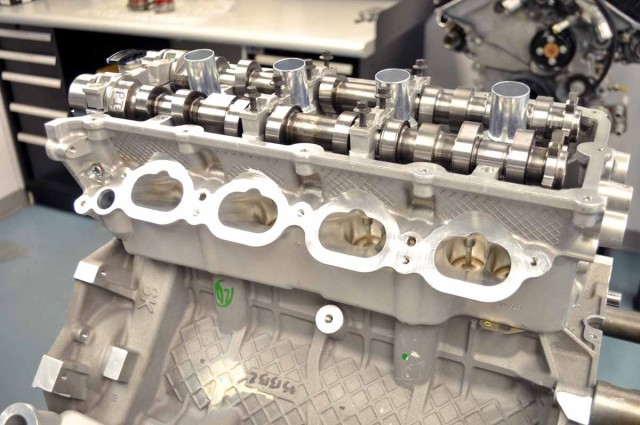

Livernois has a variety of CNC porting programs that have been developed in-house through hundreds of hours of research.

Custom camshafts are installed into a set of Livernois CNC-ported cylinder heads stuffed with their own engineered valves and a spring package from – yep, you guessed it – Livernois Motorsports. The company works hard to develop their product and works hand-in-hand with many trusted manufacturers to produce these items.

The engine is topped off with a Ford Racing Parts Cobra Jet intake manifold.

In this application, the Variable Cam Timing is disabled. We’ve seen that in other engines in the past and were curious as to the motivation behind it in this case.

“When we get into some of the higher-end race Coyote engines like this one, we lock out the cam timing and turn off the VCT because the camshaft profiles we run are quite large, and as you put a lot more duration and to some degree, lift, you have to match it with a valve spring that’s going to keep up over 8,000 rpm. The factory VCT system is stressed quite a bit when you add more spring pressure,” says Schropp.

The VCT system as designed from the factory uses cam torque actuation, so it’s not actually moving the camshaft with the phaser and hydraulic pressure; the computer is predicting the movement at any given timespan of where the camshaft is expected to be, and then it puts the phaser in the correct position to have the variable timing be most effective.

Top and bottom views of the engine. Livernois performs oiling modifications and a bit of crankshaft profiling to help cut through the oil at high RPM.

The caveat to this design is that the VCT is impressive in situations where maximum torque is required, as in a street engine, but it presents issues in endurance applications like this where there is high RPM for long periods of time with increased spring pressure, as the wildly-swinging RPM requirements can take a serious toll on the phasers. Based on this experience Livernois locks out the camshaft timing in these situations.

Degreeing in the locked-out camshafts. A quartet of custom camshafts are used, with undisclosed dimensions. We’ll just say ‘big’ and leave it at that.

“Since they run such a narrow powerband and the engine never sees engine speeds less than 5,500 rpm and runs up to 8,000-plus, we can get away with not having the functionality of the VCT and still make more power by using the larger camshaft profile in the narrow powerband where the engine operates,” Schropp explains.

The chain guides have been modified by Livernois, and use braces designed in-house to provide additional stiffness and prevent any timing chain issues. Boss chain guide tensioners are used, as those have shown to provide the required performance in this type of application.

Another notable item on the engine is the Dailey Engineering dry-sump oiling system that’s been engineered to provide the best possible oiling in the high-G circumstances this engine will be subjected to in corner entry and exit. The pump is driven by a pulley that’s been built into the rear of the ATI Super Damper; other accessories are driven through custom-made bracketry that Livernois supplied to the customer.

(Left) The Dailey Engineering dry sump oiling system and drive belt can be seen here. (Right ) The engine is bored using a torque plate to simulate the head clamped on the block.

Of course, you’re curious about the power the engine has made, right?

“With the initial tunes they used when they were calibrating the engine, the output was in the 585 horsepower range, and then they switched to MS109 and later 114 octane fuel. With that combination and a set of stepped headers, they made a little bit over 600 horsepower from this naturally-aspirated engine on the chassis dyno,” says Schropp.

High output and built to last. The 5.0-liter Coyote is a fine example of current engineering that with the right modifications can excel in nearly any situation or circumstance.