Regardless of the care given to our classic Mopars, parts wear out from usage. Inevitably, we are forced to rebuild or replace. Recently, we got our hands on a 1967 Dart GT that appeared to be in good shape. The Dart was advertised as rust-free, and it was equipped with most of the original parts. It was purchased sight unseen, and once it arrived, our impression of it was positive. The multiple photos posted by the seller represented the Dart well. During the test drive, we noticed the suspension was soft and offered no road feel.

The suspension left us feeling less than enthusiastic – the ride quality was subpar at best. A set of gas shocks were removed from another A-body and were slipped onto the Dart. They helped, but the front-to-rear rake of the Dart was unbecoming – the rear being lower than the front. To adjust the front end ride height, we could simply twist the torsion bar adjusters to regain the height, but the sagging rear leaf springs were not adjustable, so we contacted the representatives at EATON Detroit Spring, Inc. for guidance on which leaf springs would return our Dart back to its correct ride height.

Our newly acquired 1967 Dodge Dart GT had soft suspension. After replacing the shocks, the quality of the ride was better, but the rear ride height of the Dart had to be addressed. The rear springs sagged greatly.

EATON Detroit Spring Leaf Springs

A pair leaf springs from EATON Detroit Spring would provide the latest advancements in spring technology and improve the Dart’s ride quality and suspension performance to a level better than the day it rolled off the showroom floor. Provided with several options, the heavy-duty, 6-leaf springs (P/N ML665) were chosen. While there were options to alter the rear ride height in 1-inch increments from the standard height to a 3-inch drop or rise, the standard height springs were selected. For more leaf spring information, select the Spring Tech tab at EATON Detroit Spring.

Our original 52-year old leaf springs had given up, and it was time for a new pair. Before shock removal, a jackstand was slipped under the rear differential. The Dart was originally from Southern California, and it was not exposed to the salt of Pennsylvania winters, so the rust was minimal.

An EATON Detroit Spring installation kit was required. Prior to ordering, the diameter of the U-bolts (where the nuts attach) and the distance between the U-bolt legs was measured. For our 7 ¼-inch rear-end, the mounting hardware kit part no. IKCC1011 provided the proper fit. While not required for our Dart, EATON Detroit Spring offers shock absorbers for the front and rear, as well as urethane leaf spring bushings.

Factory Leaf Spring Ride Height Check

Before the Dart was raised off the ground, the rear quarter panel height was measured at the centerline of the rear wheel. With the Dart’s suspension settled, the left rear measured 20 3/16 inches, and the right rear measured 20 1/4 inches. After noting the measurements, the Dart was raised off the ground to gain access to the springs.

We removed the shackles and springs that were secured with only a few bolts – taking special care to swing them away from any body panels on the way out.

Factory Leaf Spring Removal

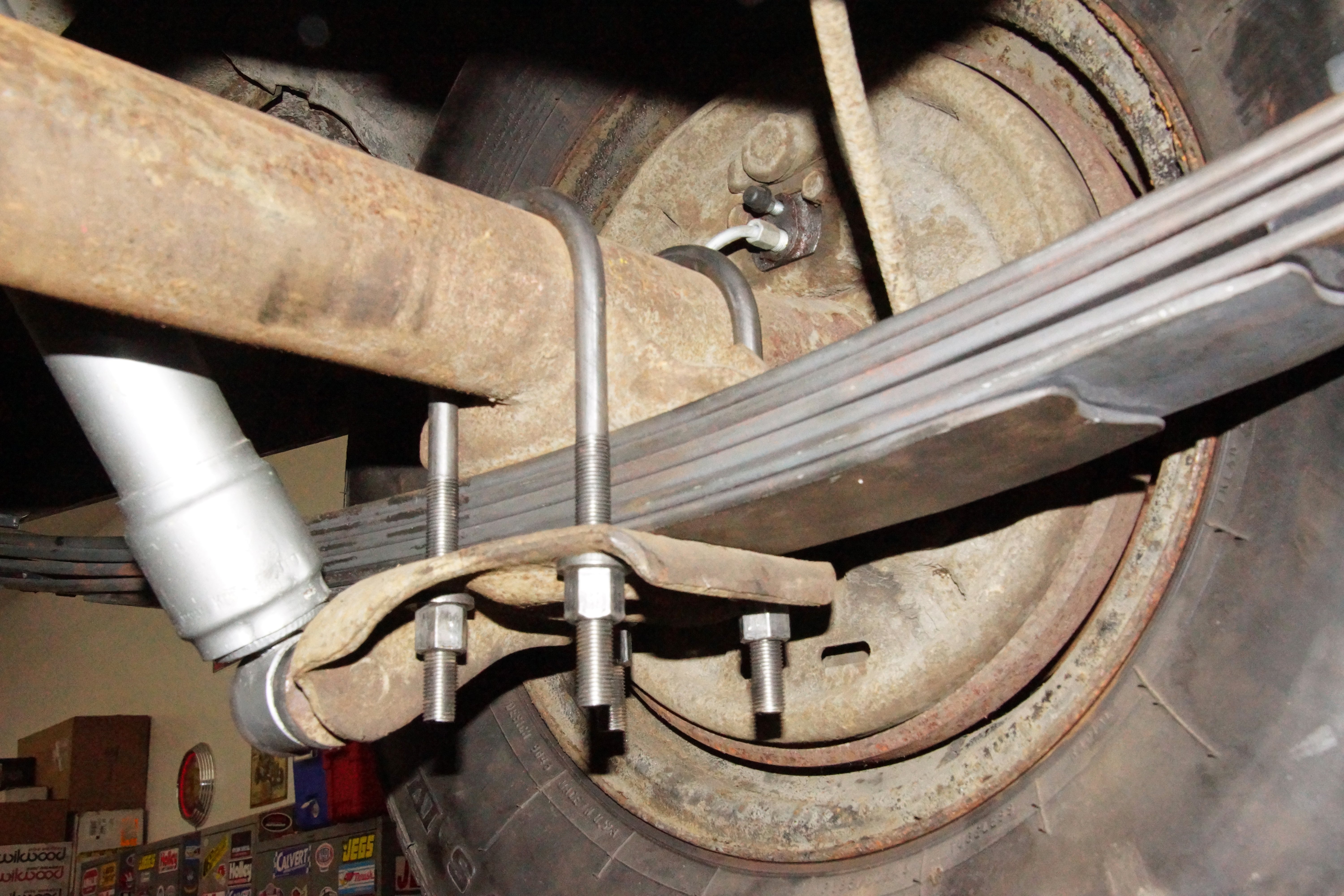

Once the Dart was on the lift, a screw jack was slipped under the rear end (on the side of the leaf spring to be removed) to support it during spring removal. The four U-bolt nuts were removed to free the shock plate and the jack separated the reared from the leaf spring.

The two shackle bolts were removed from the unibody, and the leaf spring was lowered, but still attached by the spring hanger. The four nuts that held the hanger were removed, and the spring was pulled from the unibody. With the spring out of the car, the hanger bolt was removed from the hanger bracket, and the shackle was disassembled. We placed the old leaf spring beside the new leaf spring, and much to our surprise, the old spring had a greater arc than the new spring.

However, when weight was placed on each spring, the old spring flattened significantly, whereas the EATON Detroit spring had nearly zero deflection. After cleaning, the hanger bracket was lined up with the new spring, and the bolt was pushed through the hanger and leaf spring mounting holes. The shackle bracket was cleaned and transferred to the new shackle assembly, which was installed onto the leaf spring. The hanger bolt and the shackle nuts were snugged and readied for installation.

The EATON leaf spring and the factory leaf spring were similar in appearance. Although the spring arcs looked nearly the same, when the springs had weight applied to them, the factory spring compressed with great ease, while the EATON Detroit spring barely deflected. The hanger from the factory spring was cleaned and swapped to the EATON unit. A new shackle was installed to work with the chassis mount.

Leaf Spring Installation

The entire spring assembly was lifted into place, and the hanger studs were guided into the unibody. The leaf spring was moved under the rear axle to line up the shackle bracket. As the rear-end was lowered, the locating tab of the leaf spring was guided into the hole on the spring perch of the axle housing and new U-bolts installed. We put the shock absorber back on along with the new spring.

EATON Detroit Spring Leaf Spring Ride Height Check

After the leaf spring installation, the Dart was lowered to the floor so the suspension could settle, and the hanger bolts and shackle nuts could be torqued. The ride height was measured at the same points on the rear quarter panel as before the spring installation, and the rear ride height had risen considerably. The new leaf springs provided an acceptable rear-to-front rake appearance.

Top Left: The EATON Detroit spring hanger was slipped into the chassis. Top Right: The leaf spring was swung into place. Bottom Left: New U-bolts were guided over the axle housing and into the shock mount plate. Bottom Right: The shock was remounted to the shock plate.

Checking the Angles

The Dart’s driveshaft and alignment angles needed to be checked, so the Dart was driven to Pennsylvania College of Technology to use their Hunter Alignment equipment. An inclinometer was used to measure the working angles of the U-joints on the driveshaft. After the smooth drive, our belief was the driveshaft angles had not changed, but we wanted to guarantee the new springs did not upset any driveshaft angles. Incorrect angles could lead to vibrations at specific vehicle speeds.

With the rear-end of the Dart supported by a bridge jack and the Torqueflite in neutral, we measured the the U-joint cap of the driveshaft and transmission yoke. The rear U-joint of the driveshaft and the U-joint of the differential yoke was also measured. The difference between the front working angle and the rear working angle was 0.5-degrees. All three of the measurements were within specifications.

Top Left: The rear ride height was rechecked after the installation of the EATON leaf springs. The ride height was measured at the same points on the quarter panel as it had been before the spring installation, and the rearend had risen considerably. Top Right: The shackles had the desired rearward lean. A straight up-and-down shackle would be acceptable, but a forward leaning shackle would not; which would mean the spring was too short or installed incorrectly. Bottom Right: An inclinometer was used to measure the driveshaft angle. All of the angles were within the factory specifications with the new EATON Detroit springs. Bottom Right: The Dart's suspension was professionally aligned with a Hunter alignment machine.

Pleased with the driveshaft angles, our concern moved to the thrust angle of the rear end. The thrust angle is an imaginary line drawn perpendicular to the rear axle centerline as viewed from above the vehicle. With the vehicle weight on each tire and the Hunter alignment heads mounted to each wheel, the thrust angle of the Dart measured -0.32-degrees. Our preference was a measurement closer to 0-degrees, but for the street, it was fine.

After the alignment, the Dart was taken for an energetic drive that had a firm ride quality, but not unpleasant. With the rear-end ride height increased by more than an inch, we experienced a more comfortable driving position, and the Dart tracked straight at speed.

The Dart’s rear end was raised more than 1.5 inches, making its appearance more presentable with a slight rear-to-front rake. Ride quality and road feel are drastically improved, and the seated position in the Dart is much more comfortable.

Wrapping It Up

The EATON Detroit Spring leaf springs reestablished the desired rear-up, front-down rake found on most muscle cars. The installation of the leaf springs was well worth the effort. The ride quality of the new leaf springs greatly surpassed the factory springs. If you have a pair of worn out springs on your ride, check out Eaton.