One of the hottest drag racing classes of the last decade has been the NHRA‘s Factory Stock Showdown (referred to as Factory Super Cars by the NMCA). This class has gained an impressive following from the fans and racers alike as Detroit’s “big three” battle it out one 1/4-mile at a time.

Currently, there are only three cars that are allowed to race in this class: Ford’s Cobra Jet Mustang, Dodge’s Drag Pak Challenger, and Chevrolet’s COPO Camaro. On a given weekend, any one of these cars is capable of winning, and it usually comes down to a hundredth of a second or less between these competitors.

This class has stringent rules that the competitors have to abide by, keeping the competitors closely-packed. But what makes this class so attractive? We spoke with long-time racer Dave Barton, General Manager at Ray Barton Racing Engines.

Dave started racing when he was 18-years old and is now in his 23rd season. Dave said, “I started racing in the Factory Showdown in 2013 when they combined the naturally-aspirated cars with the supercharged cars. At this point, the class was just an exhibition/experimental category. No one knew how to run the show yet. The naturally-aspirated cars got a handicap start, which was a good attempt to bring everyone together, but it would never work. Nobody wants to watch a heads-up race with a staggered start.”

I was on top of the world driving a Chevrolet Camaro. The Dodge boys weren’t too happy with me. -Dave Barton

When he first started class, Dave was racing a Challenger, and MOPAR didn’t have a supercharged engine combination. Unfortunately, he was stuck with a naturally-aspirated 426 HEMI engine. Daves’s first Factory Showdown win was in 2013 at Charlotte. Dave said, “I was the first Dodge Drag Pak in the 8-second zone when I won.”

In 2016, the NHRA decided to make the Factory Stock Showdown an official class, with SAMTech as the headlining sponsor. Dave and his team decided to ditch Dodge’s program and jump into Chevrolet’s, which turned into the best season of his racing career, achieving three wins in the first three events. Dave says, “I was on top of the world driving a Chevrolet Camaro. The Dodge boys weren’t too happy with me.”

When asked why he thought the Shootout cars were so popular, Dave said, “People can relate to them because they’re real factory cars with race engines using factory parts. Pro Stock and NASCAR started with the same concept, but over time they ruined everything about it. Nobody looks at those cars in that same way anymore. The Factory Stock Showdown brings excitement back into drag racing again, and the factory wars are more alive than ever.”

The Factory Stock Showdown brings excitement back into drag racing again, and the factory wars are more alive than ever. -Dave Barton

In our opinion, Dave couldn’t have said it any better. How many times have you watched a Pro Mod or a Funny Car and thought, “Man, the new Camaro looks good?” Most of the time, we’re trying to figure if it’s a Chevrolet, an import, or one of the many makes and models of cars out there that are barely recognizable. Don’t get us wrong; we love Pro Mods, Funny Cars, and Pro Stocks, it’s just not a class that will affect people when they decide to buy a new car.

Another thing that makes this class and the cars in it so cool is that they’re attainable. You could run down to the dealership today and buy a new Challenger, Camaro, or Mustang and make it look just like a shootout car. You can even buy the same parts if you decided to step up the performance using off-the-shelf components. It also doesn’t hurt that these cars make a ton of power, do wheelstands, and run in the 7-second zone. And with big names behind the wheel, like Leah Pritchett, Mark Pawuk, and Dave Barton, everyone takes notice.

While these cars look like their mass-produced counterparts, they’re very different. Since these vehicles are designed to go fast in a straight line, several changes have been made. Overdrive transmissions have been shelved for the lighter and stronger three-speed units. The independent rear suspension has also been replaced with a tried-and-true solid rear axle. Safety equipment, like roll cages and other necessities, needed to be installed to keep the drivers safe. All of the creature comforts, like air-conditioning, power steering, and luxury seats have also been removed to free up some room as well as weight.

There’s no doubt that launching the car is a big task every time you pull up to the line. – Dave Barton

Even with all of these modifications, the Shootout cars can be a handful to drive. Dave explains, “There’s no doubt that launching the car is a big task every time you pull up to the line. We are limited to a 9-inch wide tire, and the suspension has its limitations. We are constantly living on the edge in the traction department. The track conditions make it tough on the crew chief, and they have to decide how far they want to push the envelope each round. This is why the NHRA intends to keep it a small-tire class. It keeps it interesting, to say the least.”

One company that helps Barton Racing Engines do what they do is ATI Performance Products. ATI has a long legacy in the racing world and builds some of the top racing products in the industry. The company manufactures transmissions, torque convertors, and engine dampeners for these now 7-second cars. All of ATI’s products are designed to handle the rigors of racing as well as high-performance street driving abuse.

Barton Racing Engines has been a dealer of ATI since the 1980s. The race team currently uses ATI’s Super Damper, torque converters, and flexplates on their COPO Camaro. Dave said, “I can honestly say that every single win I have, ATI products was involved in one way or another.

Super Damper

Since we weren’t exactly sure how a Super Damper worked, we reached out to Harvey Baker, Marketing and Sales Assistant of ATI, to get the inside scoop on this product and others used for Factory Shootout Cars.

Harvey explained to us that ATI Super Damper is a harmonic damper that is designed to reduce the harmonics in the engine caused by crank vibration. This unit is an elastomer-style harmonic damper that works like the OEM-style assembly. The difference between a Super Damper and a factory part is the use of multiple O-rings and a captured inertia ring. This product is also SFI-approved, tuneable, rebuildable, and is great for engines that like to turn serious RPM.

We took the Super Damper that we offered for the street version of the Factory Stock cars and modified them to fit the rulebooks. – Harvey Baker

Unlike OEM-style dampers with a press-fit elastomer material, a Super Damper employs a combination of various 70 durometer O-rings and a unique, full-captured inertia ring to dampen harmful crankshaft vibrations. Testing by General Motors has shown that the ATI damper is very efficient when it comes to displacing crankshaft twist. ATI was able to take this technology and integrate it into the supercharger pulley, creating the Supercharger Super Dampers, adding powerful protection inside the crankshaft blower pulley. This design also eliminates the need for an additional blower pulley on a stock balancer. The assembly also features an external belt drive that will accept a wide array of blower belts.

Since ATI manufactures the Super Damper for a variety of makes and models, one might think that an off-the-shelf unit would work on a Factory Shootout car. However, this is not the case. Harvey explains, “We took the Super Damper that we offered for the street version of the Factory Stock cars and modified them to fit the rulebooks. They are allowed to run different combinations and don’t run power steering or air-conditioning.”

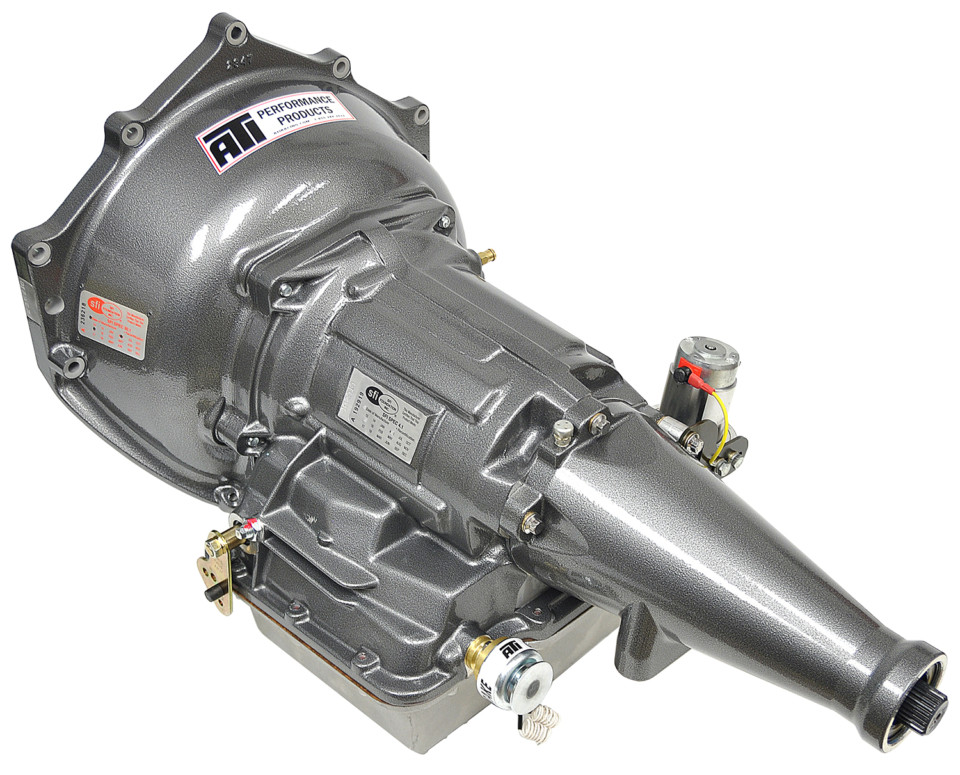

The SuperCase Transmission

One of the many challenges for ATI Performance Products when developing products for these shootout cars is the sheer size and weight of the vehicles. Harvey explains, “Your average bracket racing car, for example, is normally about 2,800 to 3,200-pounds. So now we have to take what we know about this type of setup and adapt it to a Factory Stock car that could weigh over 3,500-pounds. These cars are heavy and have a lot of power. We know that everything needs to be stronger to survive.”

Since the weight of the vehicle determines what components are used in a transmission, a heavy car needs the most robust parts available to live under the harsh conditions of drag racing.

So what kind of transmission does it take to survive under these massive cars with modern-day power?

The Turbo 400 was a versatile design of its time and one of the most capable drag race transmissions ever. Its only problem is that the original GM case has not been produced in years, leaving racers and enthusiasts digging through wrecking yards, Craigslist, and even swap meets. The difficulty with buying any used item is you don’t know the history of the part, including abuse, mileage, or maintenance record. A weak, worn-out case is less than ideal for your average drag car, but especially for a 7-second 1,300 horsepower shootout contender. Plus, can you imagine Chevrolet hunting around looking for good Turbo 400 cores for its prized COPO Camaro? Not a chance. They needed a new three-speed transmission that could take a beating and was readily available. ATI’s SuperCase was the perfect candidate.

These cars are heavy and have a lot of power. We know that everything needs to be stronger to survive. – Harvey Baker

While the SuperCase was not designed specifically for the Factory Stock cars, it’s definitely up to the challenge. So much in fact that Chevrolet uses ATI’s T400 SuperCase transmission exclusively in its factory-built COPO Camaros, and for a good reason. Based on the original Turbo 400 design, the T400 transmission starts with ATI’s purpose-built drag race transmission case. The case, bellhousing, and tail housing are all cast from 356-T6 aluminum and was specifically developed to eliminate all weak points found in the original GM transmissions.

“Our cases are SFI-approved for competition use and feature a steel safety inner liner that weighs a mere 29-ounces. The addition of the safety liner eliminates the need for any external shields. With our case, the racers don’t have to run any of the shields,” Harvey explains. The “shields” that he is referring to are commonly called scatter shields. These units are used to keep the driver safe in case of catastrophic failure that can occur with an OEM transmission and case. Typically, these shields mount over the bellhousing and transmission and require the body of the vehicle to be modified for fitment. Not only are these parts a pain to install, but they also do nothing to strengthen the transmission.

“Because our case is designed to be certified, it has to be a much stronger case. Our castings, which are produced in the USA, add rigidity to the part. This rigidity not only increases the amount of power the new transmission can handle, it also improves the structural integrity of the car when the transmission is installed,” Harvey explained.

Another interesting note about the ATI SuperCase Transmission is that there are no reused parts in the assembly. ATI manufactures everything, making it a brand new unit. In the past, transmission builders had to use the existing gear sets and other components from a used transmission due to a lack of parts availability. ATI decided to invest in manufacturing its parts when OEM’s became scarce and racers began making big horsepower. Harvey notes, “This process began with the Powerglide. The more desired gear set was a 1.76-ratio, which had a helical gear in it. We developed a 1.80 straight-cut gear that is stronger and can handle a lot more horsepower. Now the racers with a lot of power want to start with a lower gear, like a 1.64 ratio. We made it in a straight-cut gear, as well, and it’s able to handle 3,000 horsepower.”

It’s safe to say that GM would have never dreamed that a Powerglide would be bolted to a 3,000 horsepower engine when they were designing it back in the 1950s.

The SuperCase features a removable bellhousing that bolts directly to the transmission case instead of the pump bolt locations. You can bolt a variety of bellhousing combinations on the transmission, including small- and big-block Chevrolet and the LS and LT engines. ATI makes bellhousings to fit most Ford and Dodge engines, as well. The cases are engineered to accept all internal Powerglide, Turbo 400, or Turbo 350 components.

The SuperCase two- and three-speed transmissions are a good fit for race cars, but this transmission would be overkill for most street cars. Plus, some people like the added driveability that comes with the four, six, and eight-speed units. The wider gear ratios help in performance as well as fuel mileage, giving you the best of both worlds. Fortunately, ATI has something for its customers that want a high-performance overdrive, too. The company builds these units to take the abuse of a heavy car for street driving and hitting the dragstrip on the weekends. These units are rated up to 1,000 horsepower, which is serious power for anyone wanting a dual-purpose machine, unlike the Factory Stock cars. These vehicles need the most robust transmission built.

While the Factory Stock class is still relatively new when compared to traditional NHRA categories, we’re always curious to see what the future holds. David gave us his input on the future of this class.

“The future looks bright for this group. There’s a lot of complaining about the parity of the class, but that will never go away as long as the three brands keep battling. The cool part is how there are literally hundreds of new cars (COPO Camaros, Drag Pak Challengers, Cobra Jet Mustangs) that have been sold and never used out there waiting to be raced one day. We certainly won’t see a shortage of vehicles any time soon. With that being said, I can see this going on for decades. I can only hope that it won’t turn into what Pro Stock is today. We need to stick to our roots and keep it simple.”

If you think about it, this class is a win-win for everyone. Teams like the Bartons will continue to push the limits of the Factory Stock Showdown car while offering a unique test-bed for the companies involved. Companies like ATI will benefit from the teams’ feedback as they continue to raise the bar for products while using Factory Stock Showdown cars for new product development. The latest products and technology will make its way to the market, helping build better race cars and street cars. Plus, we get to watch some of the coolest cars and best drivers on the planet battling it out on a 9-inch tire. How cool is that?