Despite the tumult and unrest that put a stamp on 1968, there were some amazing cultural achievements that attempted to balance everything out. Apollo 8 became the first crewed spacecraft to leave Earth orbit to circle the moon and return safely. Mattel’s Hot Wheels cars were introduced to the market, and one of the most famous 1968 Fastback Mustangs appeared on screen in the Steve McQueen movie Bullitt.

Henry McCray admired the clean lines of his friend’s ’68 Fastback Mustang. He admired the car so much that he ended up owning it.

The father of one of our video producers had been running around with a mostly stock 1968 Fastback Mustang. One of the few significant items that had been changed was an engine upgrade to a more potent carbureted 351 Windsor. From what the father/son team could figure out, the engine was a 1970 model, the peak of the muscle car factory power era. They also figured out they needed some modern help from FiTech Fuel Injection to enjoy this classic.

The 1968 Fastback Ford Mustang

Henry McCray would visit with one of his co-workers after work and sometimes on the weekends. Although he was a GM car guy by nature, he kept looking at his friend’s stagnant Mustang, just sitting in the yard collecting California sunlight.

Eventually, the tires lost all the air and the car seemed to be melting into the ground. It was about this time when Henry really noticed the car’s lines and stance. How everything flowed in the design so the car looked like it was going 100mph when it was sitting still. “If you ever want to get rid of this thing, let me know,” Henry told his friend.

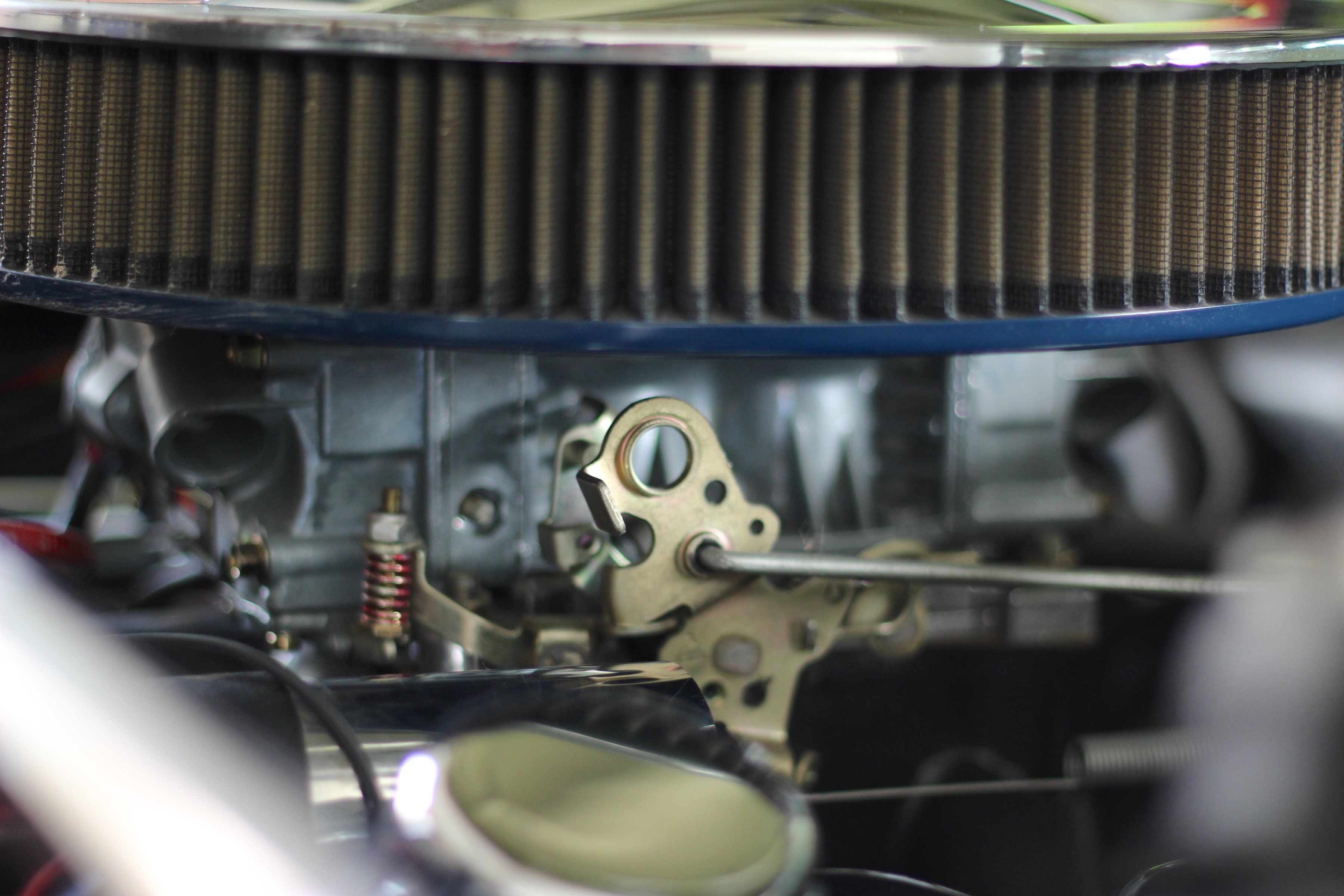

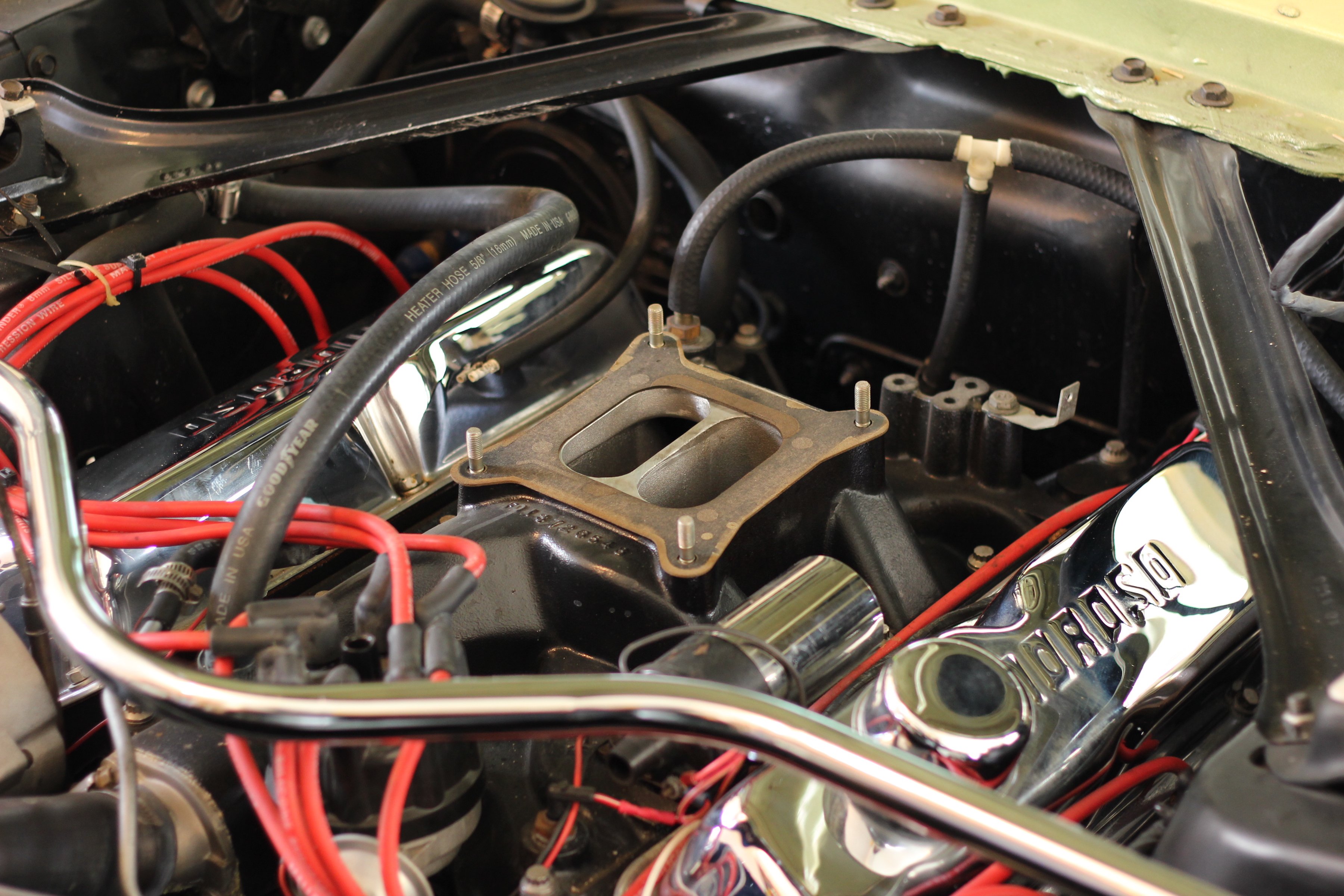

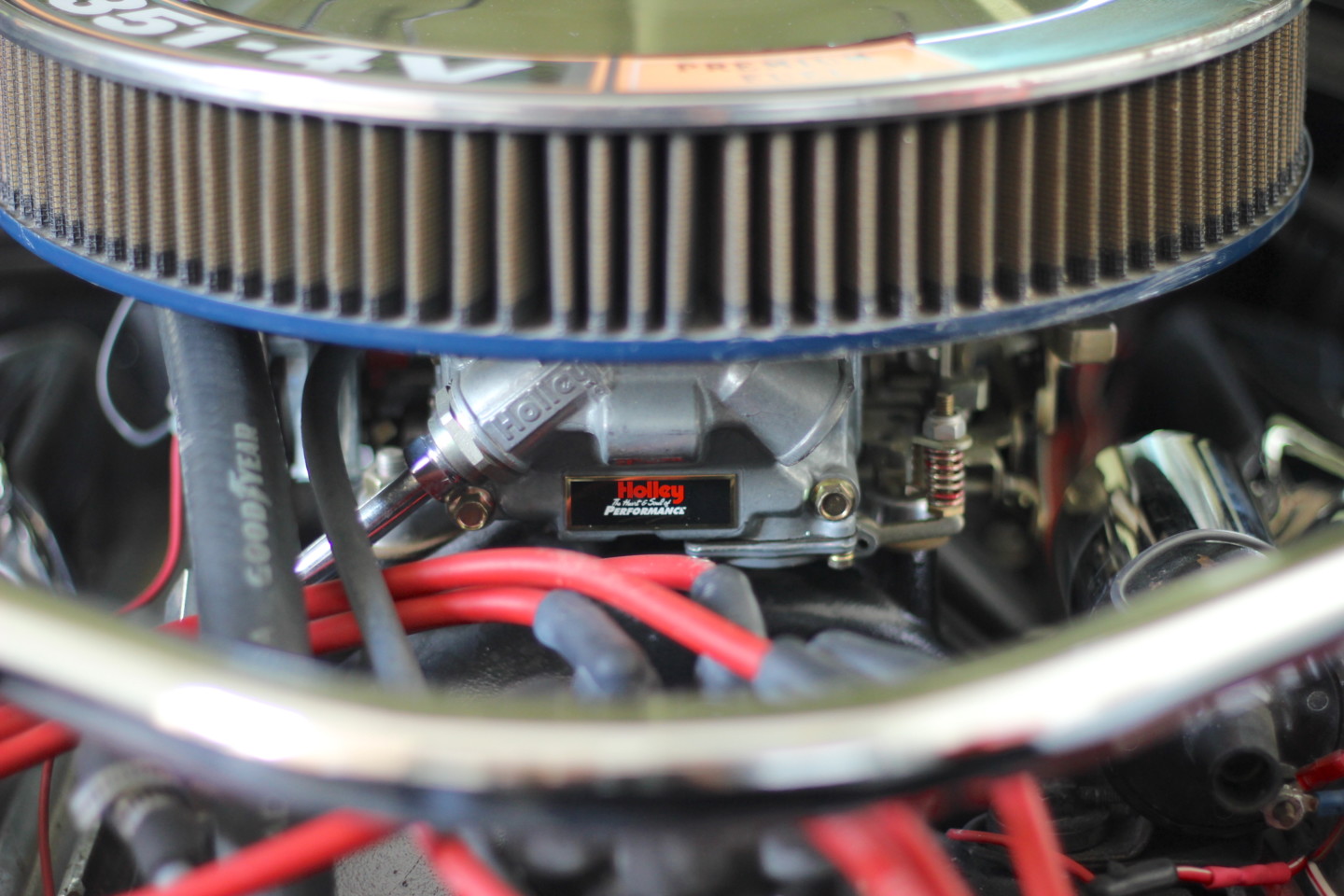

The car was fitted with a 351 small-block Ford Windsor with a four-venturi carburetor, hence the 4V designation on the air cleaner.

By the end of 1996, Henry McCray was the proud owner of a 28-year-old Sea Foam Green Mustang. It took no time at all before he had the car running around on the streets of his beach town in Southern California.

The Mustang was fed by one of the most iconic fuel delivery systems of the day, a four-barrel Holley carburetor. Henry wasn’t comfortable optimizing the carb and wanted something that felt more like his modern fuel-injected cars.

The small-block Ford was fitted with one of the most iconic carbs in muscle car history, and it was a lot of fun at wide-open throttle. “Around town in partial throttle driving, it didn’t feel like Pop’s modern cars,” explained his son Brandon. Due to a lack of experience, they couldn’t get the carb tuned efficiently to the engine, so the car was garaged until a solution could be found.

Other than the engine swap, a strut brace, and replacement consumables like spark plug wires the car was very stock-like.

Electronic Fuel Injection

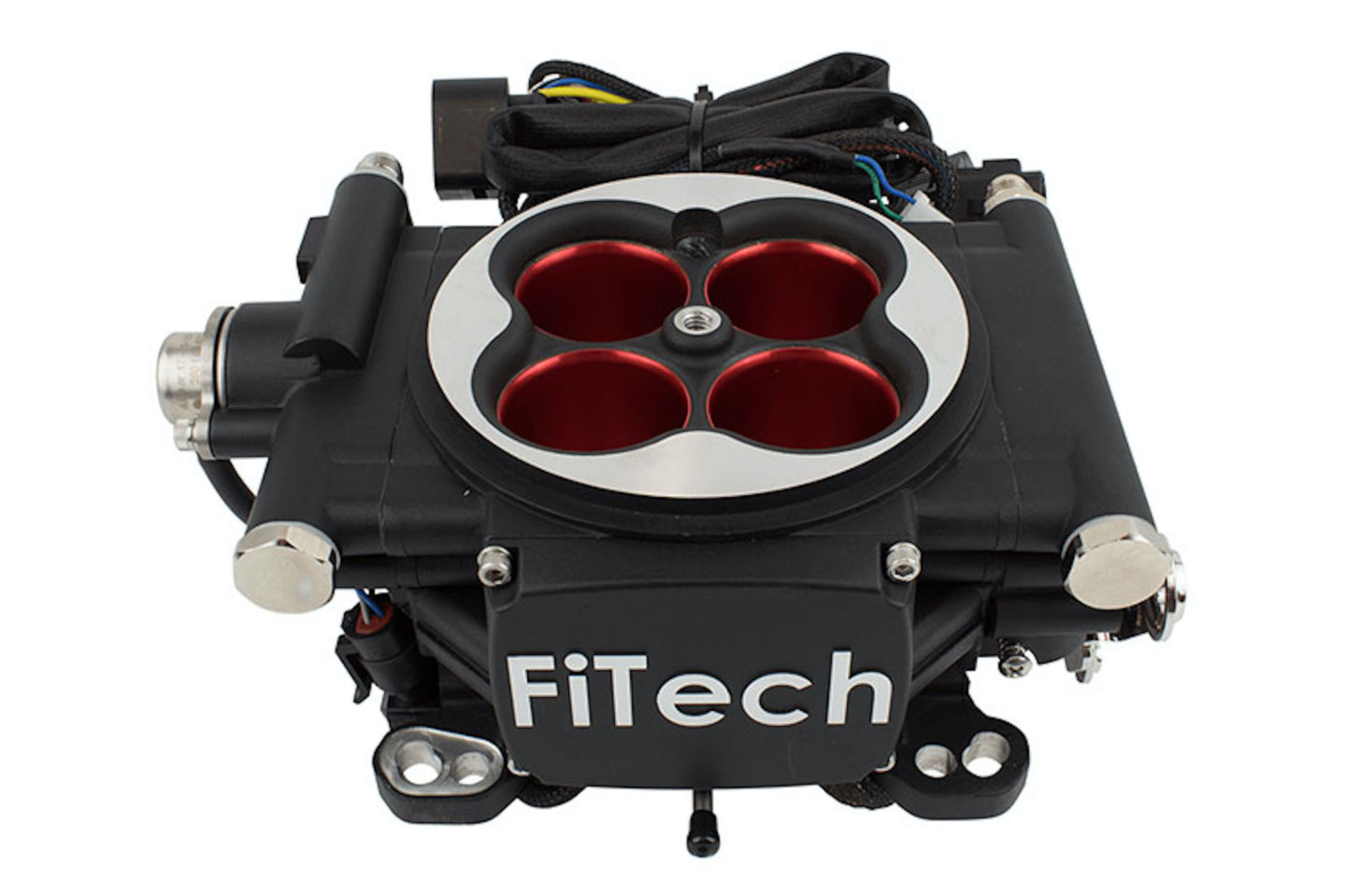

After searching around, the McCrays found what they believed to be the perfect answer to their dilemma. A throttle body EFI system that is easy to install made by FiTech. EFI systems have been around for a century, and the mechanical EFI systems made in the 1950s by hot rodders like Stu Hilborn keyed on wide-open power. Decade by decade, these systems became more and more streetable, attracting a lot of aftermarket attention.

All in all, the Holley carb is a great unit that requires very little. This one was equipped with an automatic choke and simple throttle linkage.

In the late 70s and early 80s, automotive manufacturers found they could use a single-point injection (throttle-body) instead of a multi-point or manifold injection system. The throttle body injection offered a low-cost way to deliver fuel and meet the ever-tightening exhaust emission regulations. Best of all, the system bolted to the engine like a carburetor. It looked and acted like a carburetor, which took away some of the fear over a new system to enthusiasts.

At the same time, the throttle body EFI units provided better drivability. The engines started easier, ran smoother, and got better fuel use. Best of all, you didn’t have to be an expert to tune them to prevent hesitation. Now, aftermarket companies like FiTech have refined the system to make more power, flow more air, and get better throttle response with performance EFI units.

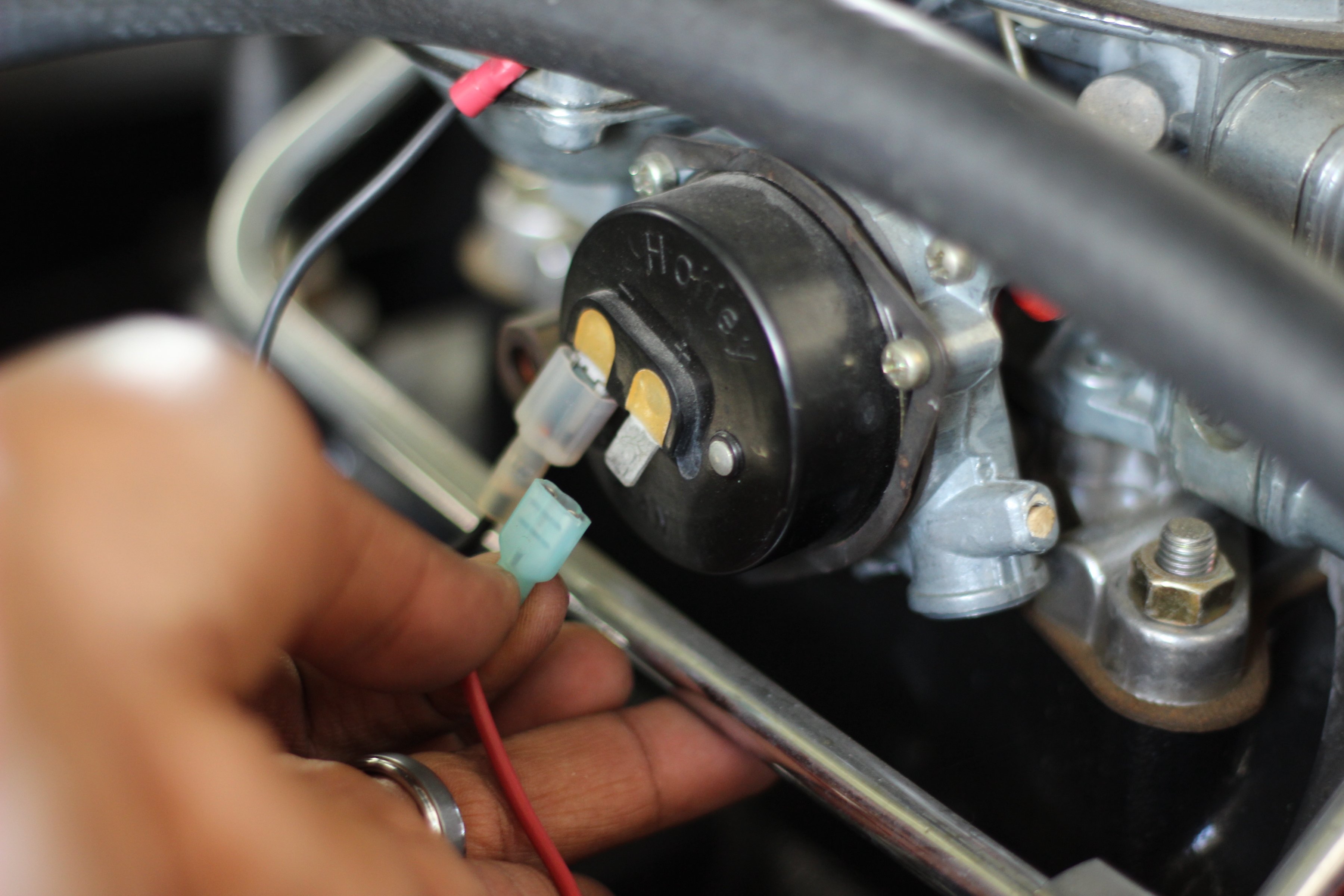

Henry couldn't wait to get started pulling wires and removing linkage to get the old system off.

Fitting A FiTech Go EFI System On A Vintage Car

One of the many benefits to a throttle body EFI unit is the ease in which they can be fitted to a vintage vehicle without major modifications. For many enthusiasts, this is a job that can be accomplished in their driveway over a weekend. This is especially true with modern fuel systems that support the higher PSI throttle body units made today. For this upgrade, we selected FiTech’s Go EFI (#3004) and their Force Fuel delivery kit (#50004).

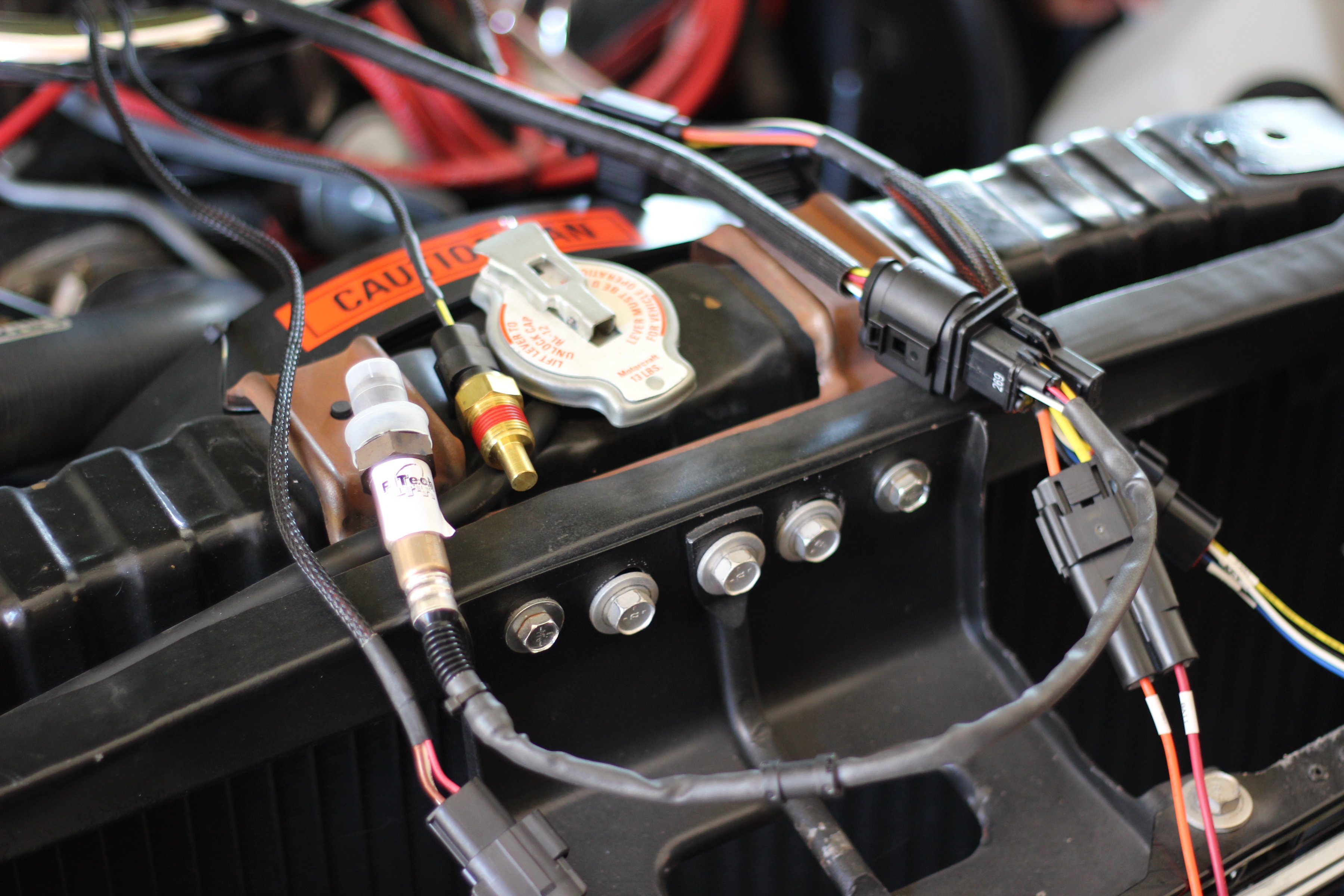

The Go EFI unit is a self-learning, self-tuning system that uses a handheld controller for initial setup. From there, the self-tuning program uses the wide-band O2 sensor, to continuously make adjustments to correct the air/fuel ratio to changing climate and altitude conditions.

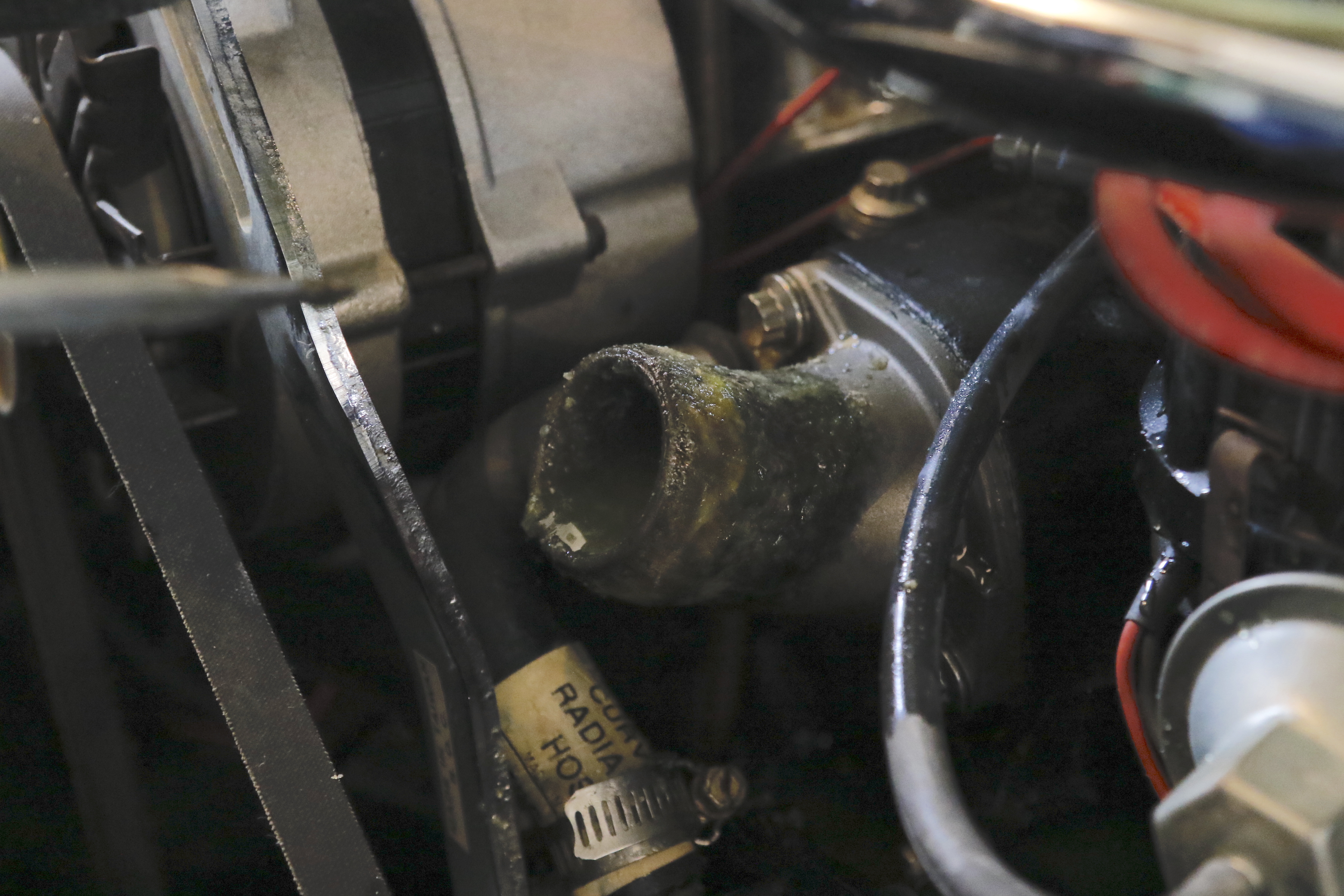

Removing the thermostat housing to replace it with one that supported a temp sensor, Henry ran into some more disturbing news. A good cleaning and flushing of the block and he moved forward with the installation of the new thermostat housing.

An engine control unit (ECU) mounted on the throttle body uses other sensors like the throttle position sensor (TPS), manifold absolute pressure (MAP), and intake air temperature (IAT), and fuel pressure sensors to control fuel delivery.

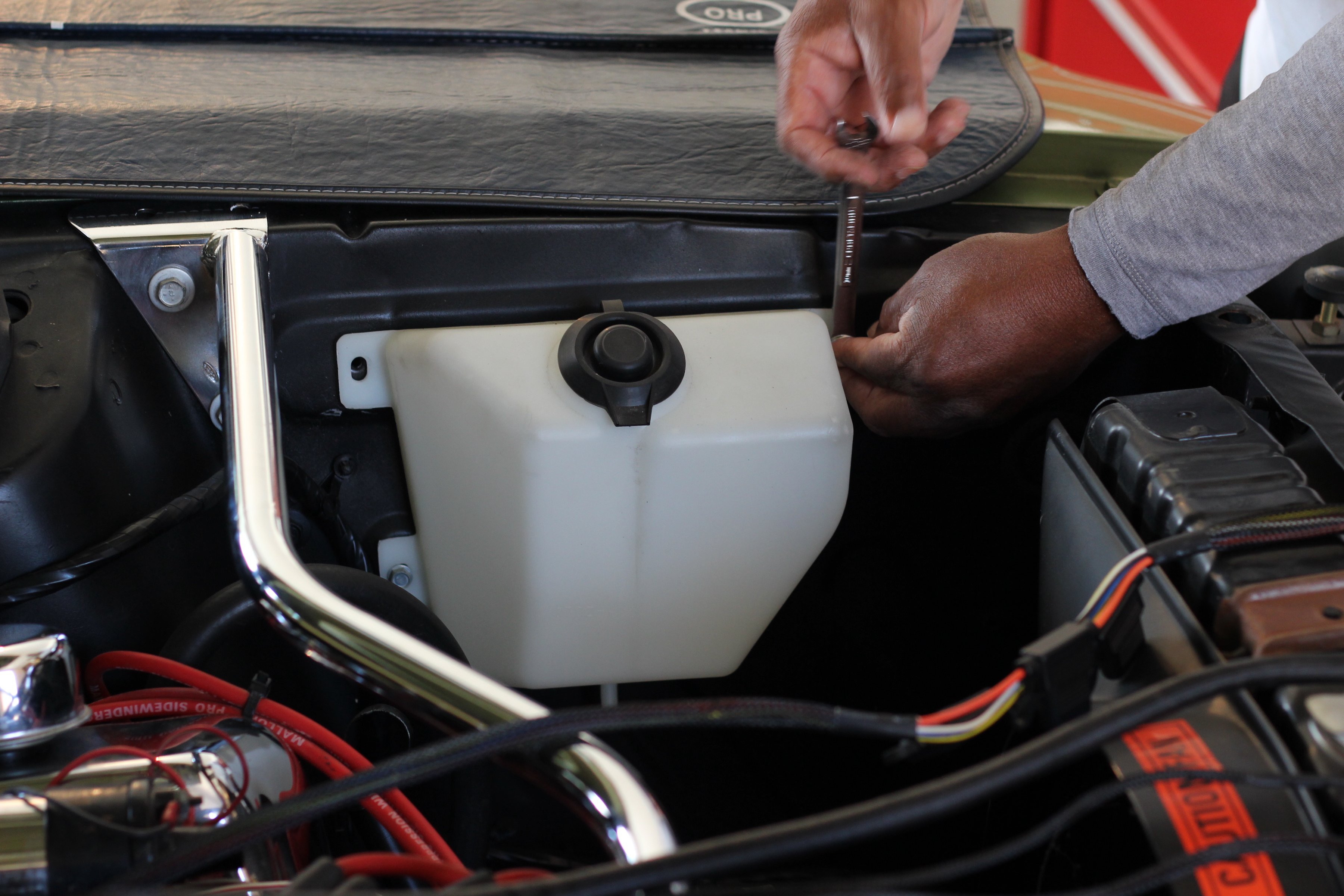

Looking for a place to put his new Force Fuel unit, Henry decided he could lose the windshield washer reservoir and put the fuel pump unit in its place.

As far as getting fuel to the system, there are two different methods. Fuel pressure supply to an EFI system is much higher than the traditional carburetor setup. This means you will have to modify or change your fuel supply system to a high-pressure system. One way to do that is with a frame-mounted inline external fuel pump. This method will require routing a return fuel line and changing the plumbing for the supply side of the system, as well as mounting the new electrical pump to the vehicle’s frame.

Henry pulled the old carburetor off, removed the baseplate gasket and replaced it with the new one supplied in the FiTech kit, and put the new throttle body system on.

The alternative method and the one Henry chose for the Mustang, is to use FiTech’s Force Fuel kit (Part #50004). This allows you to use your existing engine-driven fuel pump and lines while only requiring the Force Fuel pump to be mounted in the engine bay in a location of your choice. The Force Fuel system is suitable for engines up to 600 horsepower, which is far more than Henry needed at this point.

As we explained earlier, Henry replaced the old rusting fuel tank with a new one fit for the application.

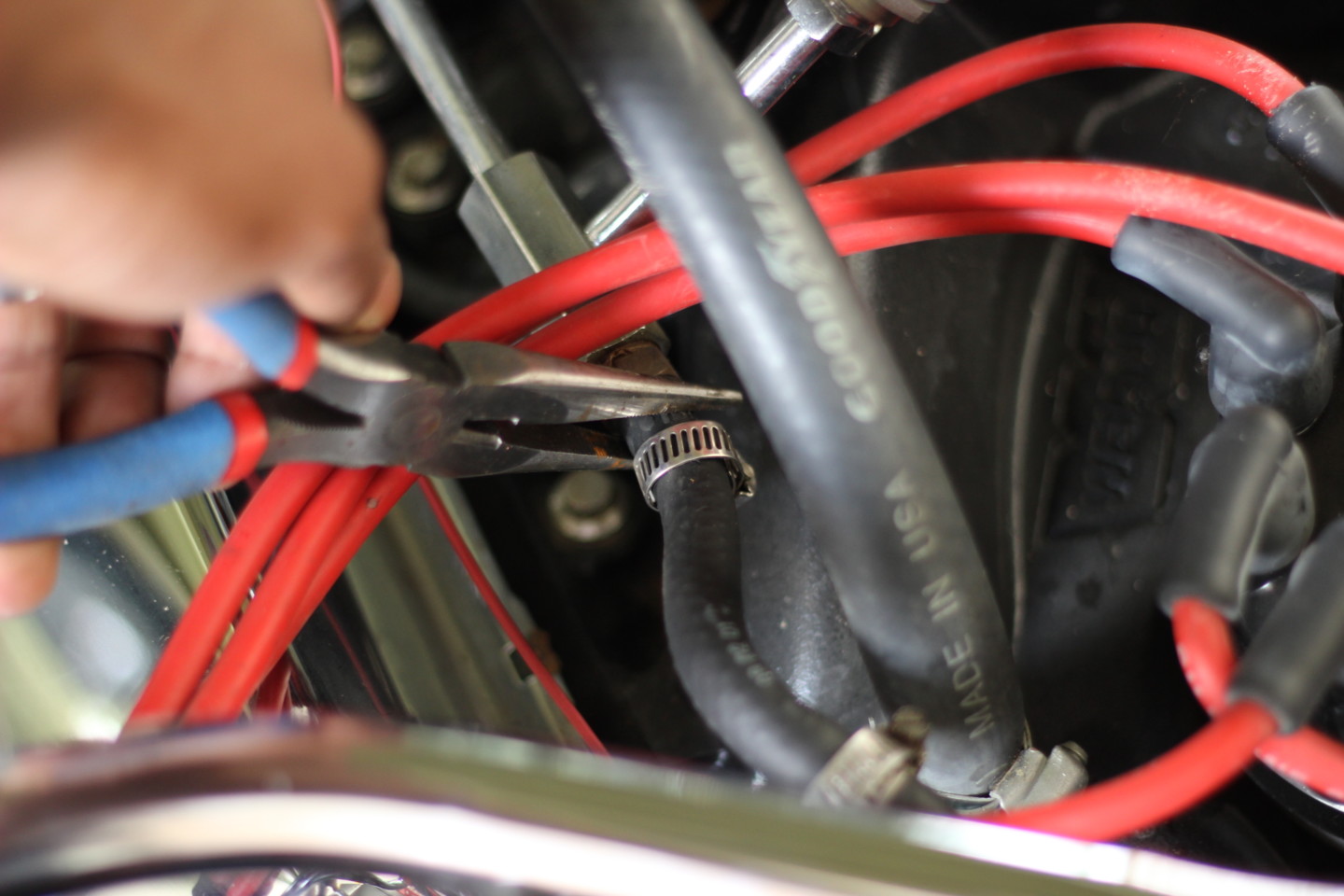

He ran a new high-pressure fuel line to the system, holding it in place with zip-ties until he could replace them with Adel clamps.

The Installation

First … and this is said often but we cannot stress it enough, read the instructions completely before you start. Make sure you understand the process and know what tools and components you are going to need BEFORE you take anything off or being the installation. Stopping and starting a system installation and long delays are the greatest causes of lost parts. Don’t be that guy.

The installation itself is pretty straightforward and doesn’t require special tools. Common hand tools are all that is required unless you need to weld in the O2 bung in your exhaust system. The O2 sensor is a must-have item for the system to work properly.

The FiTech system is manufactured to be simple to install with almost all wiring done with connectors. Simply plug the sensor connector into the EFI harness and you're done. Throttle linkage, air cleaner, and other components that mounted to the old carb will easily attach to your new EFI unit.

Any leaks in the exhaust upstream of the O2 sensor will give inaccurate readings and make the self-learning part of the EFI system very angry as it tries to keep up with the corrections. You’ll want to make sure the bung is welded into the exhaust tube properly. This may mean taking it to a local exhaust shop to have the O2 bung welding in by pros.

Special Instructions

- Only use high-pressure fuel lines and EFI-rated flared fittings. You will have leaks or worse if you don’t.

- Don’t mix 45-degree and 37-degree AN fittings. They look similar but will not work together. 37-degree fittings are commonly sold at auto parts stores and speed shops. 45-degree fittings are sold at hardware stores for use in household plumbing.

- Ensure your fuel tank is vented to prevent back pressure issues inside the tank.

- Make sure the O2 Sensor is installed in the exhaust ahead of the catalytic converter.

- Use the correct vacuum ports for positive crankcase ventilation, brake booster, transmission modulation signal, or other vacuum references.

- Use shrink wrap on all wiring connections.

Performance

Like we discussed in the intro, EFI units help optimize the fuel/air ratio on vintage cars. Often overlooked is how much performance is actually gained by these modern EFI kits. Many of these Throttle body units flow more air than the stock carburetors. Greater airflow increases the performance of your engine simply by allowing it to breathe better. Plus, more airflow will certainly help with other modifications that you have made or will be making in the future.

By improving the flow and fuel delivery you can expect to see additional gains through exhaust headers, performance air intakes, and other previous mods. Like we always say: Performance is a good thing.