At this point in the Project F-Word saga, the F100’s transformation to Pro Touring thrasher is well underway. In case you need reminding, we’ve already installed a Silver Sport Transmissions TREMEC transmission, QA1 bolt-in suspension system, big Baer brakes, new Rocket Racing wheels and Toyo tires, a Strange rearend, and a full custom exhaust from Holley.

IDIDIT provided us with a 1967-72 Ford Half-ton Truck Retrofit, Tilt, Floor Shift, Steering column for Project F-Word.

In this installment, we’re looking to our friends at IDIDIT for a few steering components, and also utilized Earl’s Performance Plumbing, Power By The Hour (PBTH), and MOMO for the parts needed to complete the installation.

When Ford Muscle staffer Ivan Korda was in the planning stages of this build, he reached out to Eddie Mohr at IDIDIT to choose the perfect parts for the job. The final list includes a 1967-1972 Ford truck steering column, steering wheel adapter, a Borgeson Double-D stainless steel shaft, and two U-joints — one for the rack side and one for the mid-shaft.

The Right Parts

The chosen column features an eight-position tilt, four-way flashers, a 3-7/8-inch GM wire plug, knobs and levers, and a pre-welded underdash mount. The column is 31-inches long with an extendable lower output shaft.

IDIDIT's 6-Bolt OE Type Quick Release Hub was chosen to work with our new MOMO steering wheel. More on that later!

“This is a bolt-in column with a custom length shaft,” explained Korda. “It is collapsible, so you can decide where you need it to make the downward turn to the rack.”

“IDIDIT provided Ivan with our 1967-72 Ford half-ton truck retrofit, tilt, floor shift, steering column,” said IDIDIT Marketing Manager Kelly Tuttle. “This column features GM-style wiring and top shaft. However, we also offer Ford wiring and top shaft, so that the original truck steering wheel can be used in order to maintain the look and feel of the original column. IDIDIT columns have been designed and manufactured in the USA for the past 35-years so that we can ensure superior components and workmanship are being used to produce top-quality products.”

While we went with a GM-style column to fit a larger range of steering wheels, IDIDIT also offers a Ford-style column for Ford trucks. “The Ford-style column comes with a Ford-splined top shaft to fit the original or a Ford-style steering wheel,” Kelly explained. “The GM-style has a GM-splined top shaft for a GM or AMKT steering wheel (most of which are GM splined).” So basically, it’s a matter of which steering wheel you would rather run in your F100.

Installing our new IDIDIT steering column was a breeze. The original unit was removed and the new one was bolted in its place. The pre-welded under-dash mount matches the original bolt pattern, so no guesswork needed!

IDIDIT also provided a Borgeson Double-D stainless steel steering shaft. These specific shafts are designed to be flexible (no, not literally) to fit a variety of applications. They are available in 18-inch, 22-inch, and 36-inch lengths, and can be cut down to virtually any length. The universal joint phasing on the shaft is fixed and cannot be altered.

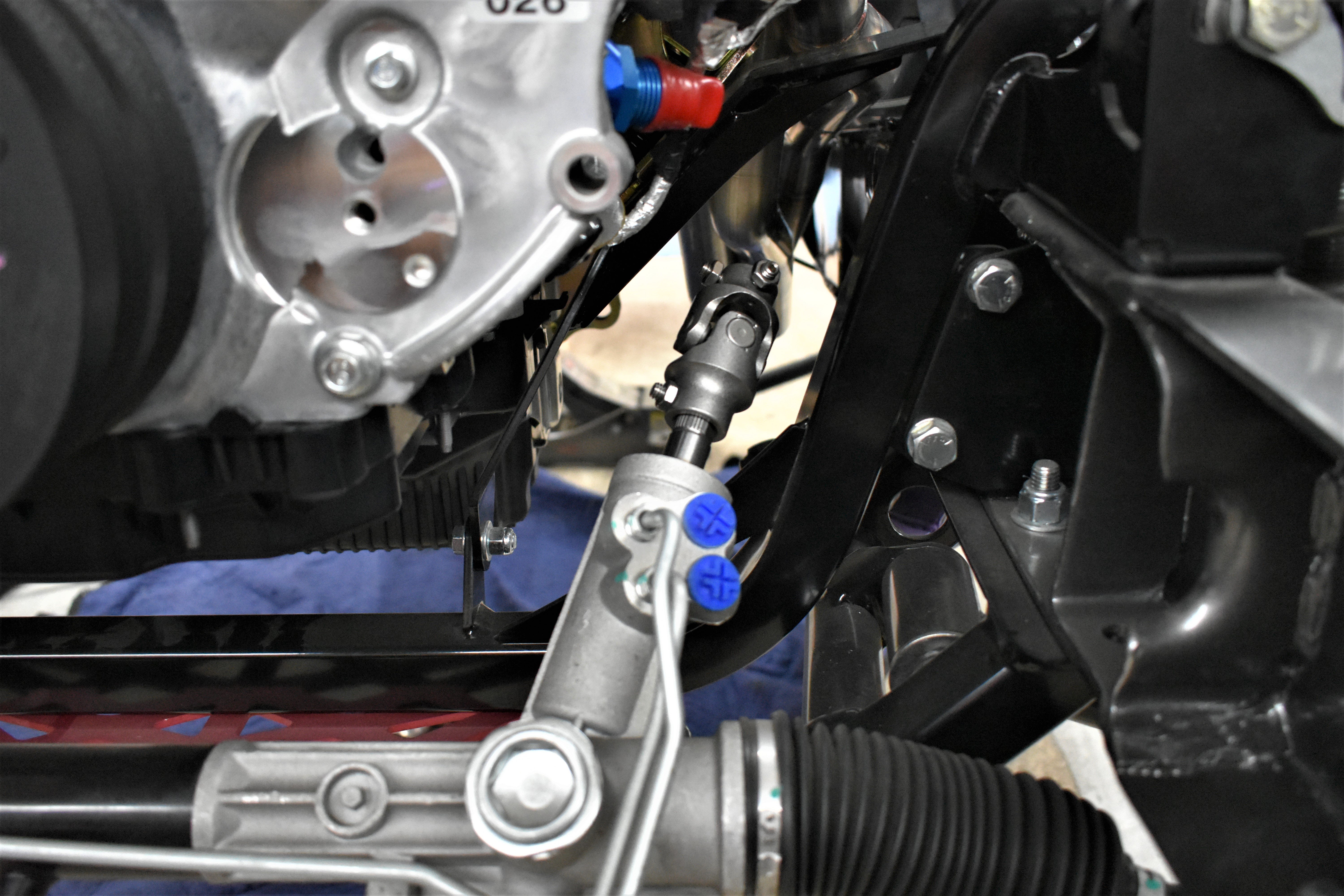

We used IDIDIT's stainless steel DD shaft and 2 U-joints to make the connection. The shaft was dimpled for the set screws to make sure they were locked in place.

A pair of matching U-joints were provided to make the connections. The stainless steel U-joint for the rack side is designed to fit ¾-in.-36 Spline X ¾-in. Double-D, while the mid-shaft U-joint fits ¾-in. Double-D X ¾-in. Double-D.

Once Korda chose his steering wheel, IDIDIT let us know we would need the 6-bolt OE-type quick release hub, so they sent that along as well to round out our list of IDIDIT components.

Seeing as there is not a set of bolt-on headers on the market for our particular application, our friend Justin Humphrey of Humphrey Design Solutions in Texas took the Hooker Headers’ 2011-2014 Mustang headers we chose for our Coyote and modified them to make it work. He did an awesome job reworking the headers to make sure they cleared our new steering shaft.

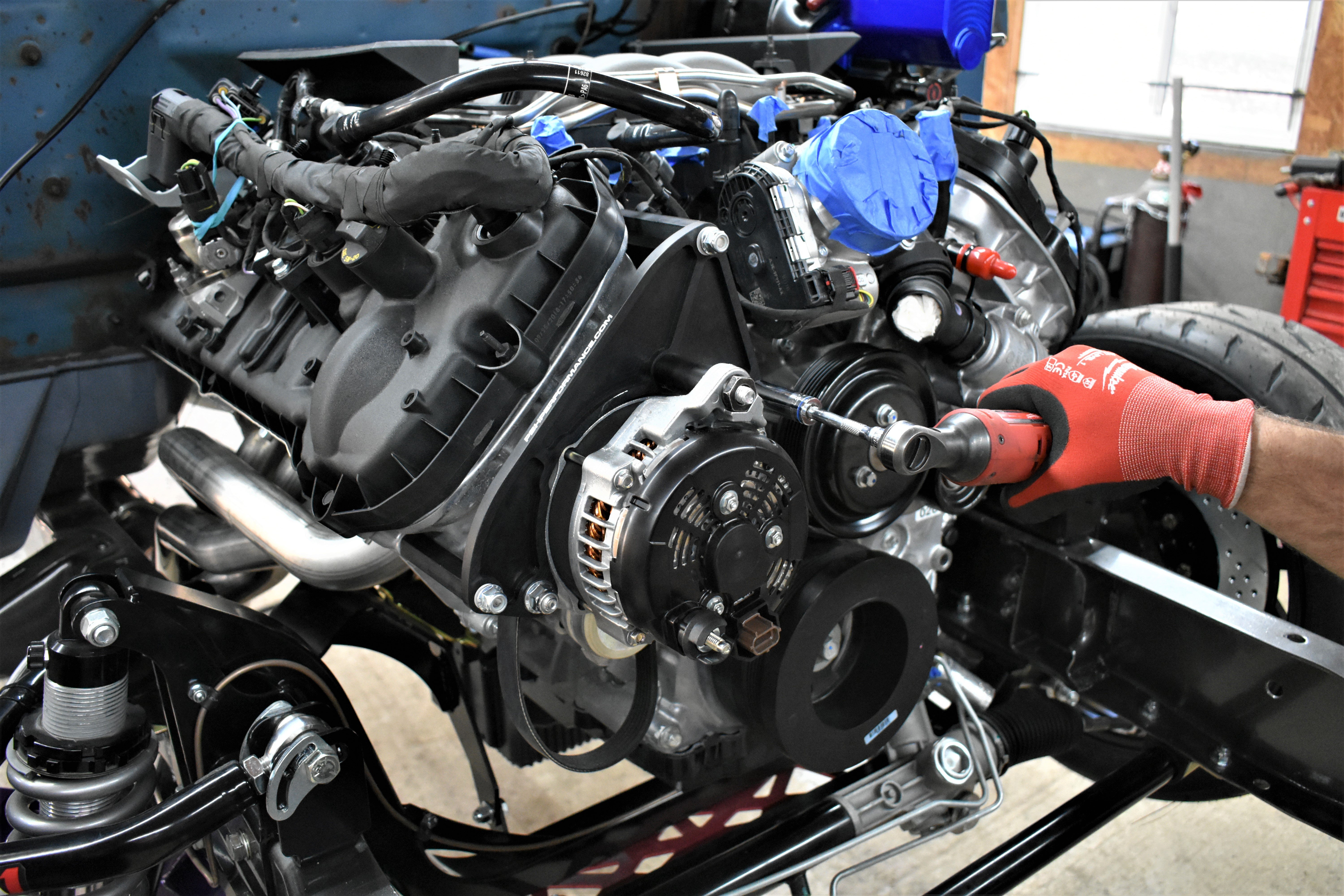

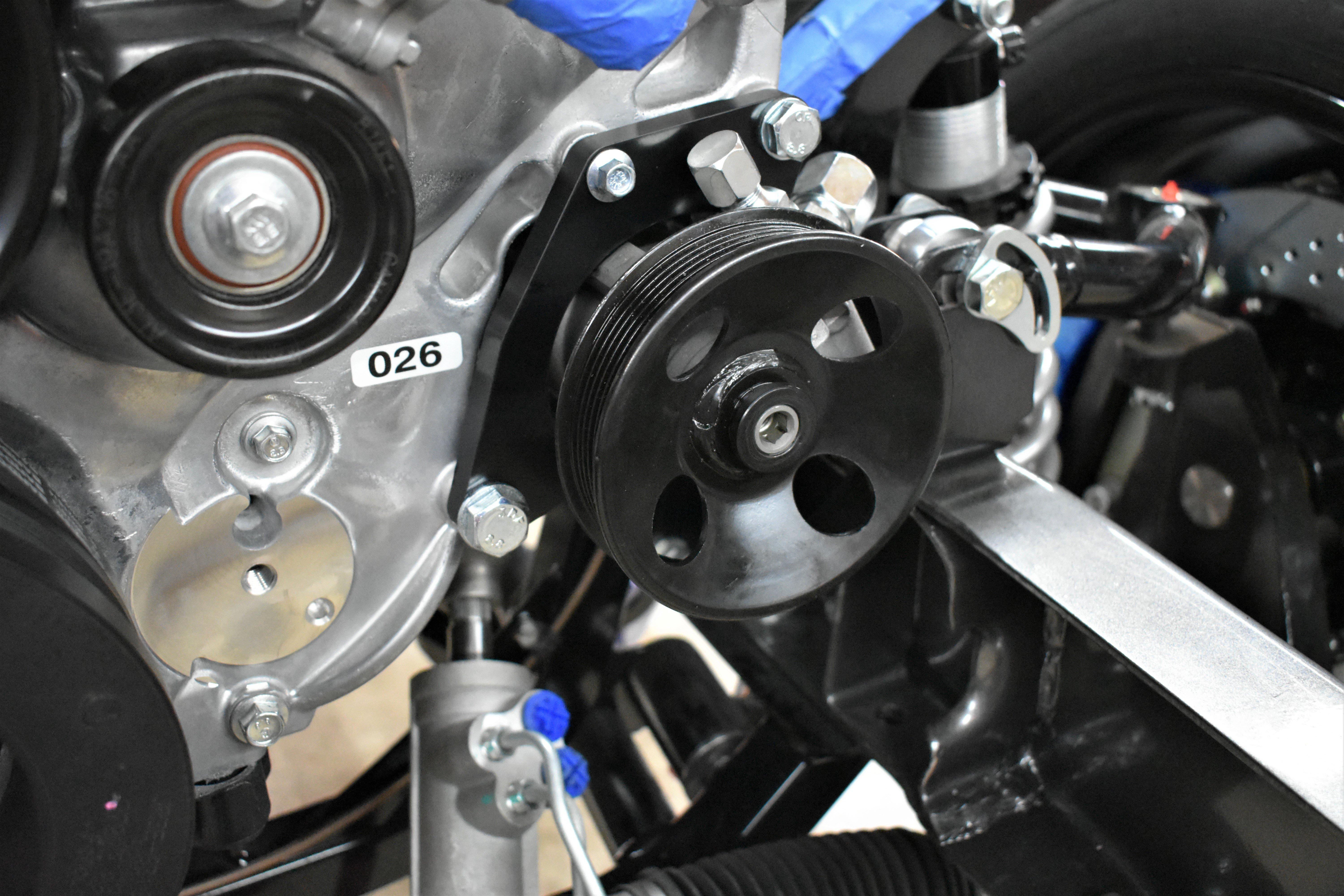

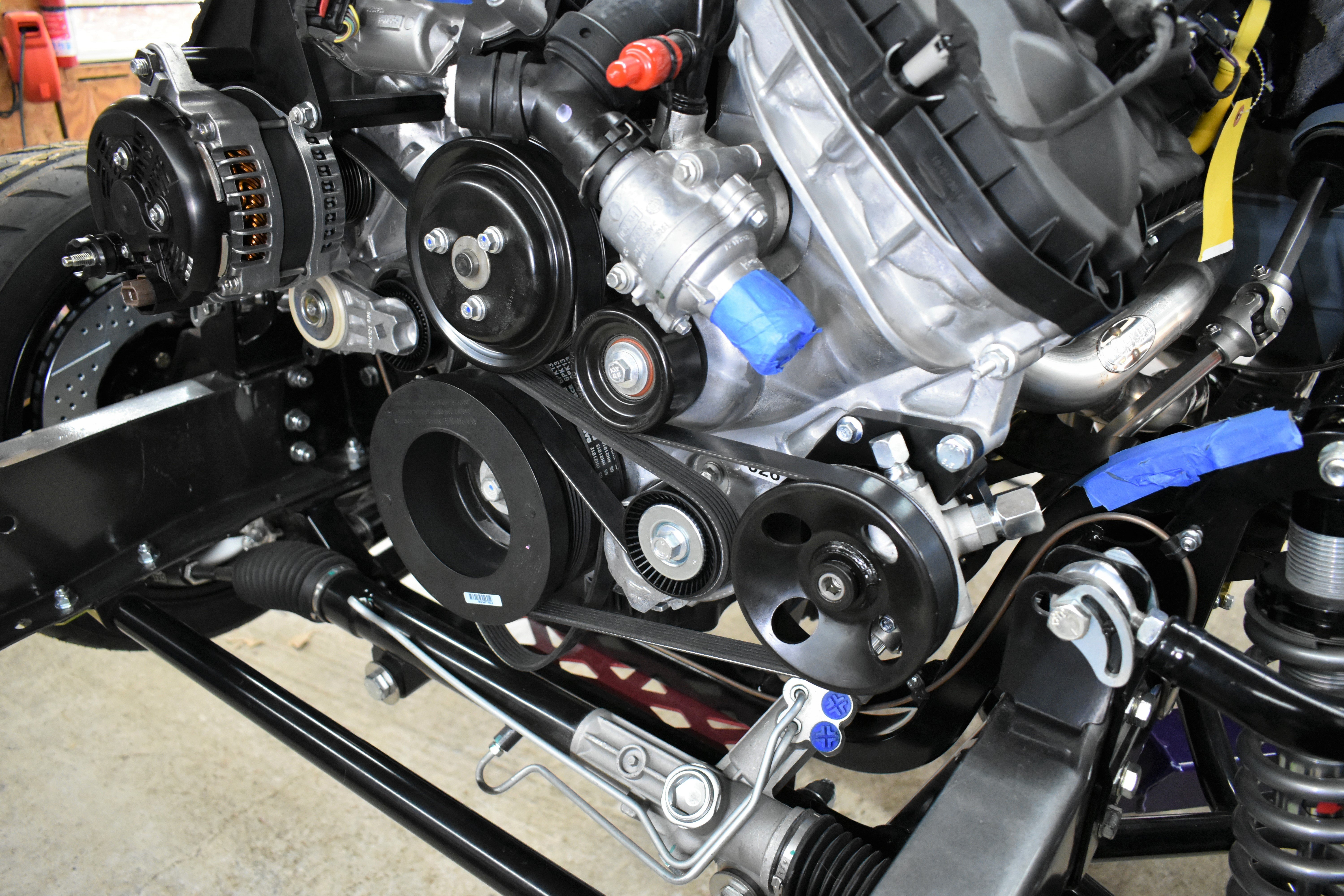

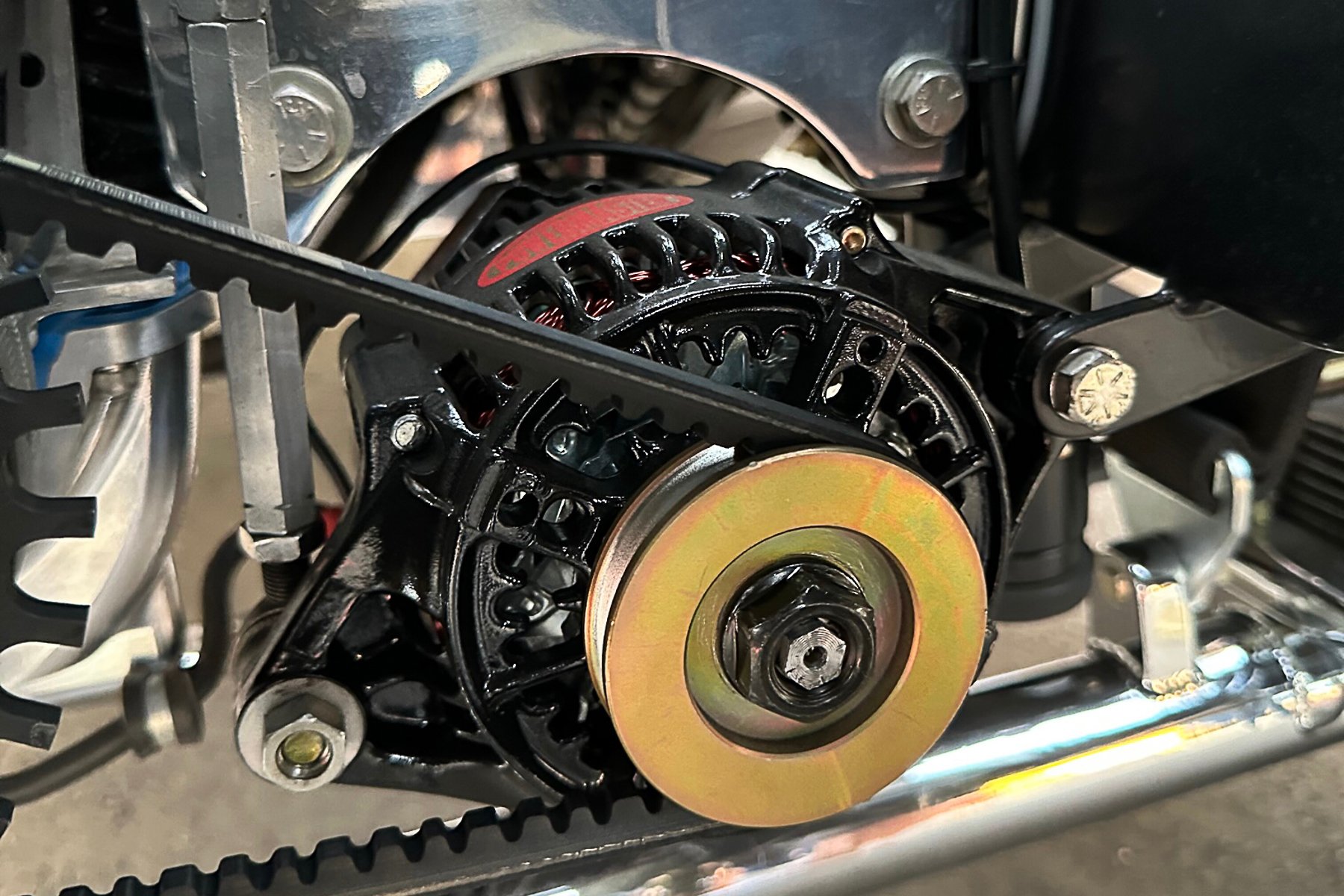

We then turned our attention to the parts needed to complement our new IDIDIT products. Power By The Hour makes a complete accessory drive kit that enables the Coyote alternator to work with a Sanden compressor — the common compressor used in classic air conditioning kits. The kit includes a bracket to run a GM power steering pump, as native Coyotes operate with electric power steering, as well as the parts needed to complete the installation. We also ordered a Coyote swap power steering pump reservoir bracket (PN: PBH-646), and the necessary GM Type II power steering pump and pulley (PN: PBH-651), which is manufactured by Detroit Speed.

Our Power By The Hour order included everything we needed to make power steering work in our F100. The parts list included the GM Type II Power Steering Pump and Pulley, Coyote Swap Power Steering Pump Reservoir Bracket, and Naturally Aspirated Speed Drive for 5.0L Coyote. The Speed Drive allows you to choose which power steering pump and A/C compressor brackets you'll need. We ordered ours with a Sanden compressor bracket and GM power steering pump bracket.

The power steering pump is compatible with any power steering gear or rack and pinion and is new (not remanufactured). For reference, the rack we’re working with came with our QA1 suspension kit and is an OE-type Fox-body Mustang rack. Detroit Speed says the pumps are made to deliver constant flow under various operating pressures, and being traverse-bearing compact pumps, they are less sensitive to radial belt loading than other kinds of pumps. The flow rate is between 3.0 and 3.4 gallons per minute at 1,500 rpm, with pressure relief of 1,250-1,450 psi. The pump and pulley also come with -6 and -10 AN fittings.

The power steering reservoir bracket was designed to work with the power steering pump bracket, utilizing the engine lift bracket mounting points on the driver’s side and fastening to the block. This takes the guesswork out of finding a location for the reservoir in the engine bay. After installation, the reservoir is mounted behind and above the power steering pump when utilizing the speed drive (like we did). This location allows gravity to feed the pump whether you use the AN feed port relocation or the stock feed port. The bracket is made in the USA, constructed from steel, and is powdercoated in a smooth black finish. All necessary hardware for installation and mounting the tank is included.

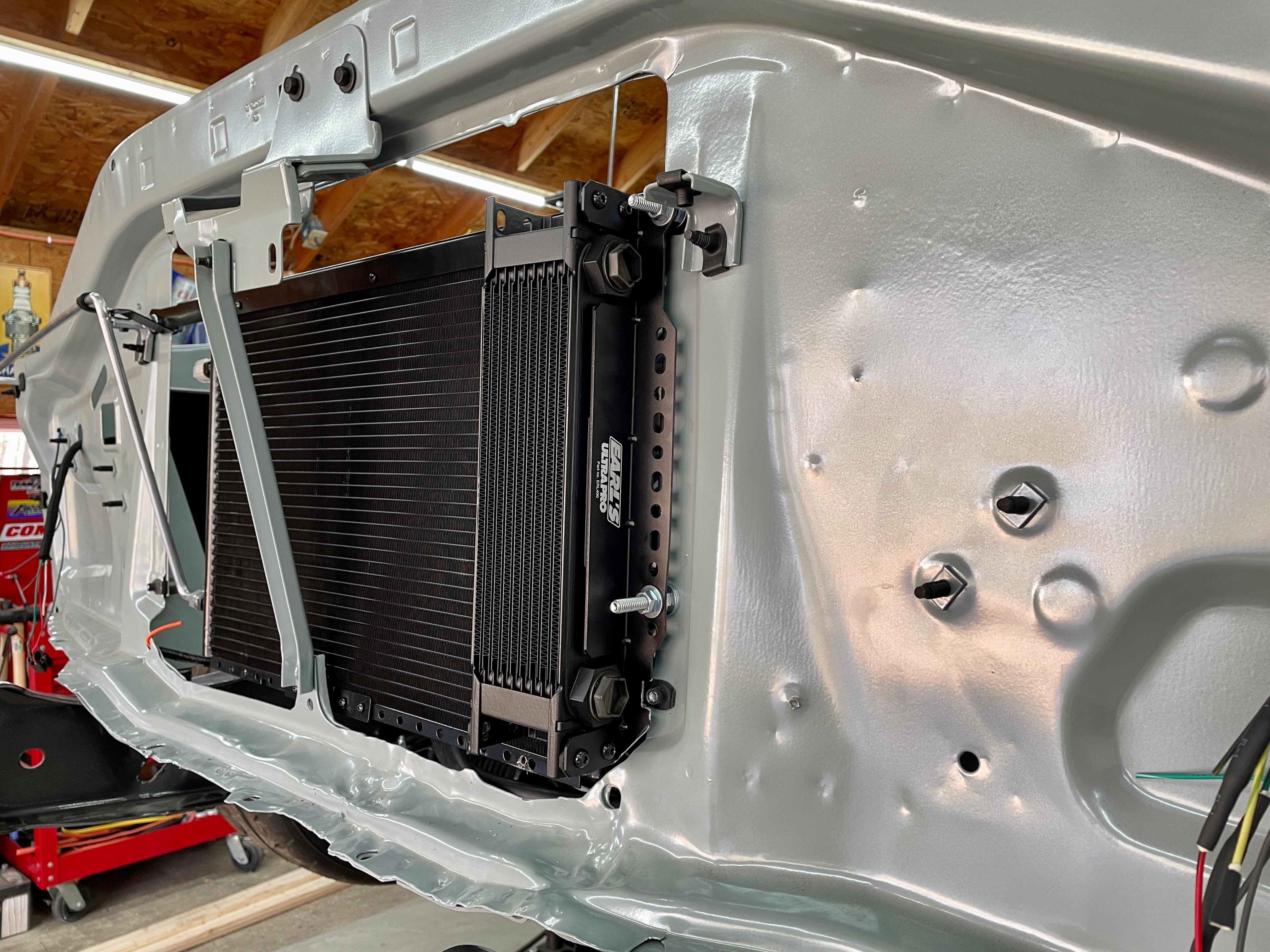

Our friends at Earl's Performance Plumbing hooked us up with all the goodies to keep our power steering running cool. Seeing as our truck is going to see Pro Touring-type duties, installing these products will definitely be beneficial.

The power drive from Power By The Hour (PBH) includes many of the parts needed to make any Coyote swap a snap, and PBH says it’s the most popular item in the extensive lineup. The kit is designed to be used with 1996-2010 Mustang GT factory modular Ford power steering pumps and the 2011+ Mustang Coyote alternator. There are options for the Modular Ford and Sanden SD7 7176 air compressor.

We went with Earl's UltraPro Oil Cooler with the matching brackets (PN: 410ERL, 400ERL). "The handy bracket made it super easy to mount," Ivan explained. "We wanted to be methodical with our power steering design and plumbing to make sure it worked for what we wanted to do. That included using a good cooler." We also sourced the oil cooler adapters, hose, and all of the hose ends from Earl's.

Basically, the speed drive is designed to allow the user to configure the accessory drive in a variety of ways, adding a power steering pump, maintaining the air compressor, relocating the alternator, and more.

To wrap up the pump installation, we plumbed everything using Earl’s hose and fittings just like on our fuel system. This also included a 10-row oil cooler (PN 410ERL) and mounting brackets (PN 400ERL) to keep the fluid in the rack cool. We are partial to black and stainless fittings, and thankfully Earl’s had all of these in stock. Once again, we used the wish list feature on Holley’s site (which you can see here). It was also crucial that we used a special fitting adapter for the rack, which we got from Summit Racing.

Finally, we reached out to our friends at MOMO for the perfect steering wheel for our F100 project. The California Wood Heritage steering wheel we ended up choosing does a great job of blending classic and modern styling to suit our project perfectly. The steering wheel is made from mahogany wood by MOMO’s Italian steering wheel artisans and is created to be durable enough to stand up to daily driving. Our particular wheel measures 360mm (the largest diameter in MOMO’s line) and features a polished spoke finish. MOMO explains that the wheel delivers a “period-correct look of legendary sports cars from the ‘60s and ‘70s.” Each wheel, including ours, features California lettering engraved on the right spoke.

Parts List

- IDIDIT 1967-72 GM Style Ford Half-Ton Truck Tilt Floor Shift w/Power Box Steering Column (Black) with custom extendable shaft

- IDIDIT Steering Shaft Polished Stainless 3/4DD Shaft 36″ Long – Part# 3000429436

- IDIDIT Steering Universal Joint Steel 3/4-36 X 3/4DD – Part# 3000013449

- IDIDIT Steering Universal Joint Steel 3/4DD X 3/4 DD – Part# 3000014949

- IDIDIT 6 Bolt OE Type Quick Release Hub – Part# 5000001070

- Power By the Hour Naturally Aspirated Speed Drive for 5.0L Coyote

- PBH Coyote Swap Power Steering Pump Reservoir Bracket – Part# PBH-646

- PBH GM Type II Power Steering Pump and Pulley – Part# PBH-651

- MOMO California Wood Heritage Steering Wheel – Part# CAL36WD0P

- Billet Specialties Power Steering Adapter Kit – Part#77901

- Earls Oil Cooler Adapters -6 AN Male to -10 O-Ring Port – 2 Pieces –Part# AT585106ERL

- Earls Oil Cooler Mounting Brackets for UltraPro Wide Coolers – Part# 400ERL

- Earls Power Steering Hose Hose Size -6 Min. Bend Radius 4 in. – 6 ft. Cut Length – Part# 150606ERL

- Earls Power Steering Hose End – 120 Degree -6 AN – Stainless Steel – Part# SS131206ERL

Making It Work

The installation of these parts was not a super-intricate process. Installing the new column was basically as easy as unbolting the original column and bolting the IDIDIT version into its place. Our steering column came with IDIDIT’s installation kit, which is used to connect the new column’s GM plug with our F100’s factory wiring. The pre-welded under-dash mount matches the original bolt pattern, so there was no guesswork included in this installation. The female end plug included in the kit connects to the IDIDIT wiring plug, and the wires are matched by function rather than color.

The new MOMO steering wheel completes the installation and also brings a heavy dose of style to Project F Word's interior.

When it came to the steering shaft, the stainless steel Double-D shaft that IDIDIT sent over was equipped with the U-joints (one on each end) to make the connection to the new steering column. We dimpled the shafts for the set screws to make sure they would lock into place.

As far as the headers were concerned, we used Hooker Headers’ 2011-2014 Mustang headers on our Coyote, as no one makes a set of bolt-on headers for our application. You can read more about the process it took to make these headers work by reading this story on our custom exhaust, but basically, our friend Justin Humphrey of Humphrey Design Solutions in Texas did a killer job of reworking the headers to make sure they cleared our new steering shaft.

Next Time

Next month we will take a closer look at the Ford Performance Gen III Aluminator installation as well as our HVAC system in Project F-Word. After that, the F100 will get a cooling system and wiring to wrap up and head to its first event. Look out for F-Word at some key events this Summer, including Holley’s Intergalactic Ford Festival.