There are many voices decrying the need for schools to focus on preparing future tradespeople. One school, Hawkeye Community College, is putting its money where its mouth is and educating its students in the best way possible. Sure there is the necessary class time as part of the daily curriculum, but when you’re teaching someone how to work with their hands, there is nothing more valuable than hands-on experience. That’s exactly what Hawkeye Auto Collision Technology program instructor, Terry Van Dyke, is doing with his students and this 1972 Chevy C10 truck.

Instructor Van Dyke is giving his students a solid head-start on their careers in the automotive refinishing and repair industry and he’s using this 1972 Chevy C10 truck to do it.

Rather than simply bide time watching students swap out spark plugs and set the timing for the umpteenth time, Terry is building their education from the bottom up.

“Taking something apart this complex is an excellent teaching tool,” explained Terry. “Many students never get the chance to disassemble a vehicle completely. Fighting through corroded components and stubborn fasteners while maintaining the parts needed to get the truck back together takes good organization and problem-solving.”

I called and talked with the owner and told him what the truck was for and we worked out a price. Next was a 4 1/2-hour drive to pick up our find. I was very happy with the truck we got. – Terry Van Dyke, Instructor

Terry had been looking for a project like this for some time. He wanted something that was challenging, but not too complex, so the students wouldn’t lose heart in the project. The Chevy truck was purchased after Terry found it on Facebook Marketplace. The original owner had used the truck daily until he passed away in the late ‘80s. The next owner used it occasionally, but the truck sat more than it moved. The last two owners of the truck had hopes of restoring the truck, but that dream was never realized.

The truck is pretty solid with a few patch panels added here and there. The plan is for the students to totally strip the truck down to its frame and rebuild it.

Terry found the truck just south of Sioux City, Iowa in 2020 and made arrangements to go look at it, hoping it might be the perfect project vehicle. The truck turned out to be all that and more, and Terry traveled the 4 ½ hours home with the truck in tow on a trailer. Then, the truck sat on the Hawkeye Community College campus, covered by a tarp until 2022, when work commenced.

Cutting This Chevy Truck’s Bed, Not Class

Being your standard heavy hauler, this truck originally left the factory in a long-bed configuration. Wanting to make this the coolest Chevy C10 project truck in the nation, the decision was made to shorten the frame and install a short bed instead. This would give the students excellent experience in cutting the frame and modifying it for both looks and performance. Both are welcome qualities with the students since there were no plans to haul rocks or other debris once the truck is finished.

The truck has some good bones. The floor looks solid and the frame is in good shape, save for having a few inches too much frame rail between the front and rear wheels.

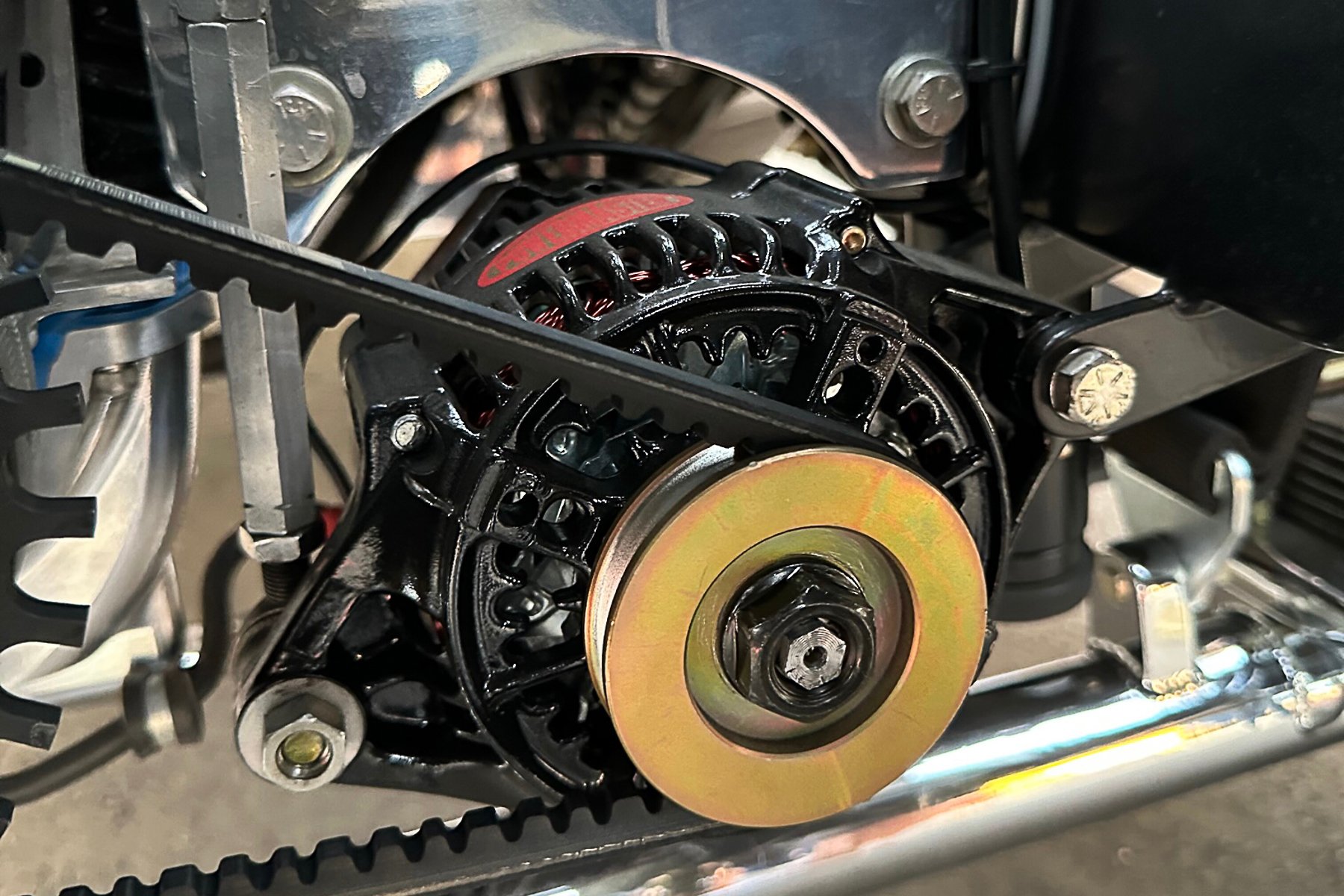

The complete list of modifications to the frame includes altering the wheelbase by 12 inches, notching the frame rails in the rear to allow for a lower stance, and installing a full array of QA1 suspension components once the frame is stripped and powder coated. An LS-swap is in store for the truck going forward and of course, the interior, wiring, driveline, bodywork, and brightwork will all be completed by the students as they hone their skills toward an education.

The students stripped the body of any remaining paint to assess the extent of the damage and what repairs will be necessary.

After the truck is completed, there will only be one thing left to do — drive the truck! Which is something that we’re sure each student is champing at the bit to do. There will be many challenges and teachable moments between now and then, but we’re sure the joy and pride in the student’s accomplishments will far outweigh any issues that may arise.

So, let us know. Would YOU like to see more stories on this truck as the project progresses? We think there are so many great things besides just having a way cool truck once the project is completed. It’s an excellent way for each of these kids to learn some valuable life skills, as well as trade-centered talents that will benefit them in the future. Send me an email below and let me know if you’d like to come along!