Every auto enthusiast has three things they are going to deal with at some point in their lives: death, taxes, and rust repair. While we don’t have a lot of suggestions on how to handle the first two, this video from Speedway Motors does an excellent job of highlighting how to get rid of oxidation in your truck’s body. Unless your vehicle spent its whole life in the desert, you could bet there is a certain amount of rust eating away at its body panels. By now, rust has made its presence known on many of these early Chevy trucks, and in some areas of the country, there’s more rust than truck!

In this case, Speedway’s Joe McCollough and Ben Vaneperen of No Coast Custom and Rod Shop start with a relatively solid specimen of Chevy’s 1967-72 C10 truck cab. Speedway Motors is documenting the build of its 1968 Chevrolet heavy hauler each step of the way so you can follow along. Today, we’re taking a look at how they repair rust on the cab of their C10.

The first part to fall subject to the hot wrench was the entire floor of the cab. Much of the surrounding mounting areas were rusted away and new replacements are available. No need to patch all the holes. When removing significant portions, be sure to brace the body to prevent twisting, which can wreak havoc when trying to fit everything back together.

There are numerous areas throughout a vehicle that can be affected by the ferrous worm, but in this video, you will see how taking the task one step at a time can really help ensure success. Having the right tools for the job doesn’t hurt either!

Creating A Rust-Free Repair

The old saying, “rust never sleeps” is true. And, if you don’t remove all the rust or deal with it appropriately, it’ll return, feasting on your fresh, new body panels. The guys begin by cutting out those rusty areas, but they also give some great advice to ponder before firing up the hot wrench or plasma cutter.

You can use a Rotabroach cutter to remove the spot welds or a belt sander like Ben. Once the welds are addressed, the remaining section of the panel can be removed.

In this video, you’ll see large chunks fall to the ground while other areas are trimmed judiciously. The trick is knowing which tactic works best for each application. Joe mentioned in this video that even though replacement panels come in some pretty large sizes, you may want to use only as much of them as necessary.

This works well when removing small, rusty areas such as cab corners, but when you are dealing with a skeletonized rocker panel or a floor that resembles a sieve, a complete makeover might be your best option for removing all the rust. That’s where careful planning and experience can be invaluable.

The new front doorpost panel was trimmed to fit and holes were drilled into the panel to allow for new spot welds. Once everything was fitted properly, the new panel was only tack welded onto the cab until everything could be fitted properly.

Since both inner and outer rocker panels were shot and much of the floor needed replacing, the guys opted to replace the entire floor, which included new inner rocker panels. From there, piecing all the compound curves of the rest of the door jamb was taken systematically, one step at a time.

Post-Rust Puzzle

Remember how exhaust installation instructions always say to install everything loosely until everything is aligned properly. While there is no such thing as “loose fitting” welds, you don’t need to go full-send when securing those new panels to the cab — at least not at first. The guys do a pretty good job of showing how custom-fit best describes those replacement panels. Even when these bodies were new and going together at the assembly plant, the panels required some tweaking.

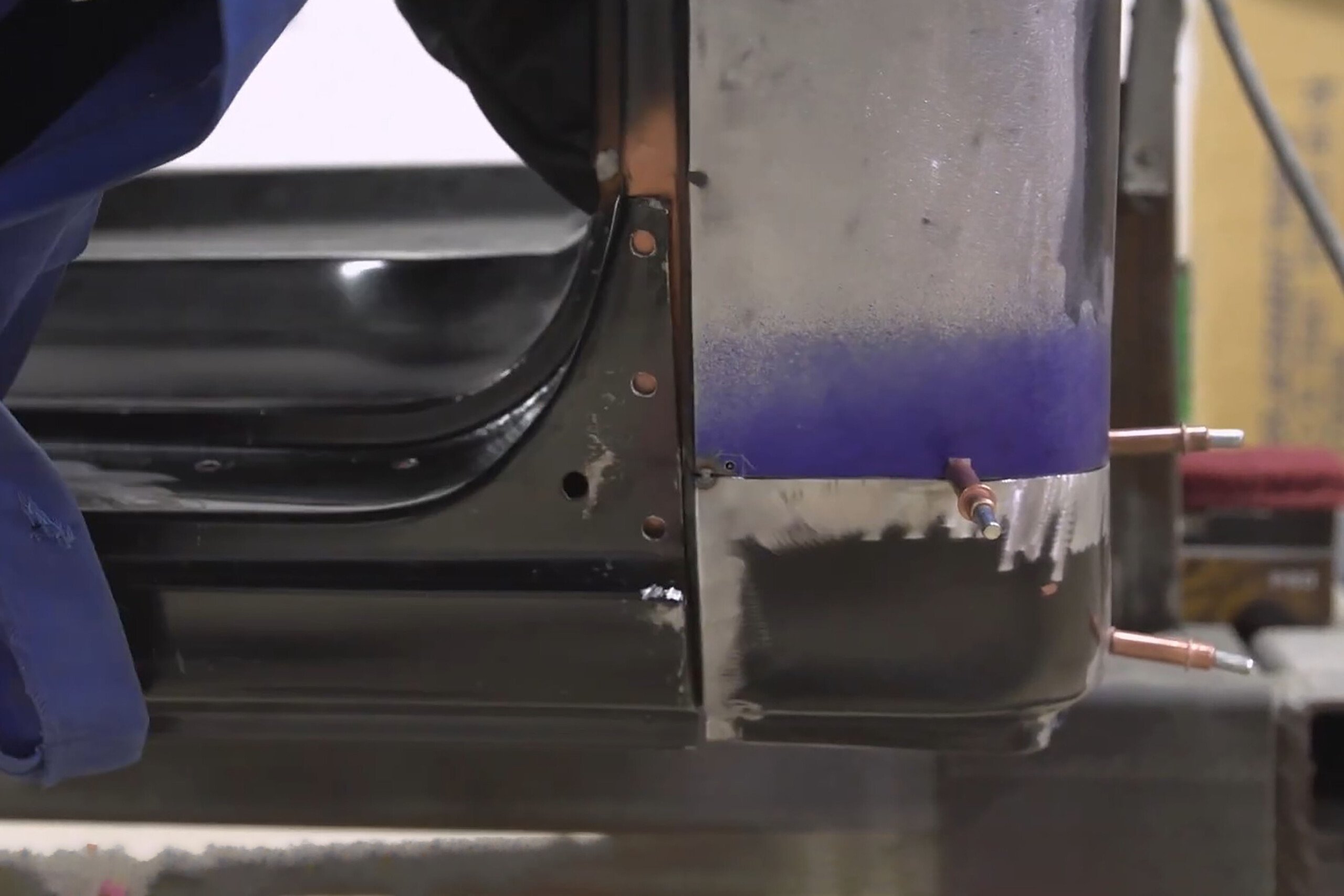

You can see how the new floor replaced all of the inner rocker panels. Once the front and rear door pillar sections were fitted and the floor installed, Ben and Joe worked the rocker panel into place to check for proper fitment. Once everything was trimmed and fitted properly, Ben sealed up the inside surfaces with a weld-through primer to help prevent future rusting.

Installing replacement pieces such as cab corners, door pillar sections, and rocker panels requires a lot of fitting throughout all the compound corners of the body. Just like an exhaust, secure the panel, but wait until everything is fitted properly before you seal the deal with a solid weld.

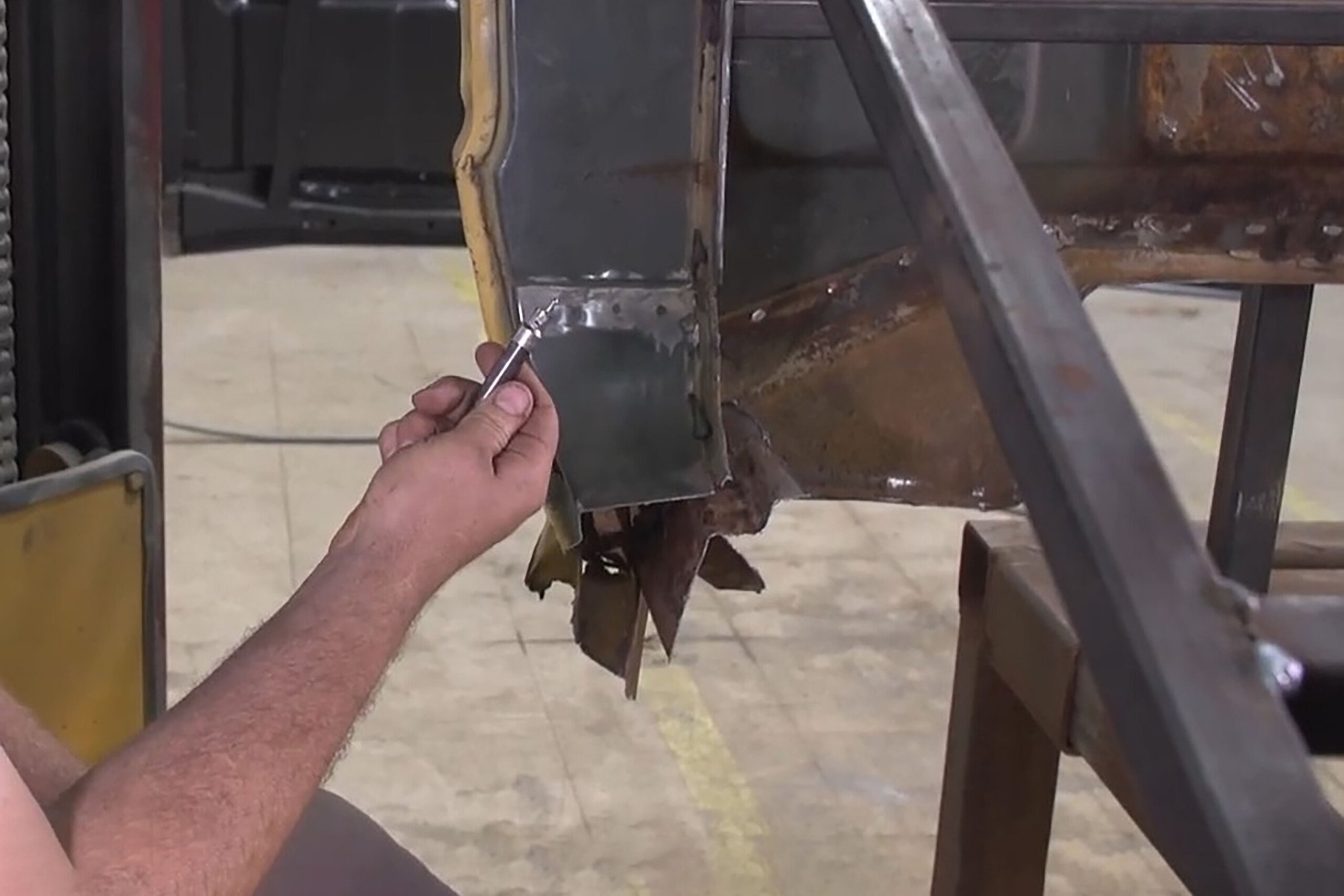

Joe marked off how much of the cab needed to be removed and then trimmed the new panel, leaving these tabs so the Cleco fasteners had a place to grasp. This allowed for a clean butt weld instead of overlapping the two panels.

Those little Cleco fasteners work pretty well at holding panels in place, but we noted Ben’s use of “tabs” to allow him to make a series of nice butt welds to hold the panels. By trimming the tabs as he welded, he was able to keep both panels even, filling the gap with the weld. This is quite an ingenious technique that keeps filler use to a minimum.

Once And Done Rust Repair

One of the reasons these trucks rusted so badly was that they were considered utilitarian vehicles. They were designed to be used as trucks and once they were consumed (by rust, work, or neglect) they were tossed aside. That meant there was little done about sealing the body to prevent moisture intrusion and rust. Even today’s repair panels are designed just like the originals and if you don’t want to deal with rust again somewhere down the road, you’ll need to take some precautions.

He removed the tabs as he stitch welded across the panel. This gave an even butt weld once finished. He then filled in by stitch-welding the rest of the opening, tapping down each weld to help keep grinding to a minimum.

It is not an insignificant step when Ben applies a weld-through primer to those areas that will be covered within the rocker panels or inside the body. While you may never see it again, that doesn’t ensure these areas will never see rain, mud, or any other oxidizer. Treating them before sealing them up is the only way to get ahead of rust, especially at the welds.

Rust Repairs That Are Better Than New

The ever-growing aftermarket surrounding these early Chevy trucks allows us to bring back many rides that might have been written off just a few years prior. And, with today’s techniques and affordable restoration products, it’s safe to say that our beloved trucks can actually turn out better than when they left the assembly line when they were new!

After grinding the welds and finishing the small repair on the back panel of the cab, you can see how everything fits together and how little filler will be necessary for preparation for painting.

The best part is that the enthusiast can perform many of these tasks with the right tools and the proper knowledge in their own garage. Check out this latest video from the folks at Speedway Motors and see how easy it can be to wipe away years of rust and neglect. Sure, it’ll take more than a damp rag and some soap, but you were looking for a good reason to crack out the Sawzall and welder anyway, right?