Like virtually all late-model vehicles, Corvettes employ electronic control modules to operate engines and transmissions as well as a variety of other functions. C5s use a Powertrain Control Module (PCM) to handle engine and transmission operations. C6 and later generations employ an Engine Control Module (ECM) dedicated exclusively to engine operation and a Transmission Control Module (TCM) to operate automatic transmissions. If you plan to make (or have already made) extensive engine and powertrain modifications, you’ll have to reprogram the PCM, ECM, and possibly TCM. If your modified Corvette could use a tune, then the FlashScan from EFILive may be just what you need.

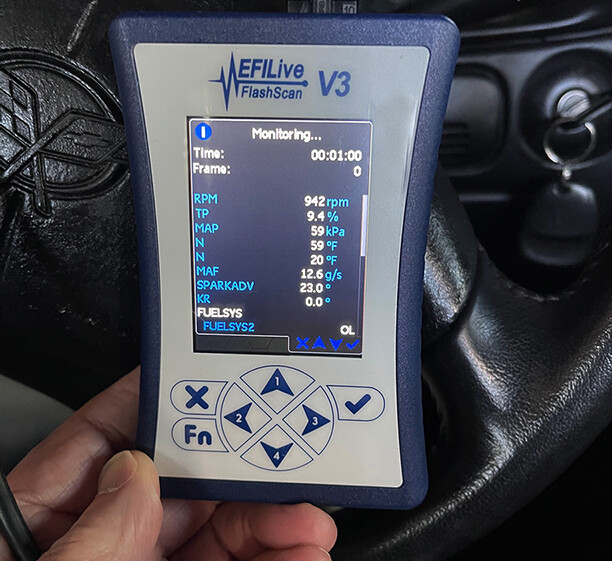

EFILive’s FlashScan V3 has a larger color screen displaying all the necessary data. The device can be set to monitor or record. The record mode is best to utilize while driving a vehicle so the driver can pay full attention to the road ahead. Also available is the V3 Autocal, designed for “long-distance” tuning. A tuning specialist located hundreds of miles away can create a tune file, download it to an Autocal and send it to a customer. The Autocal can also data log and read and reset trouble codes.

Getting Control Of Things

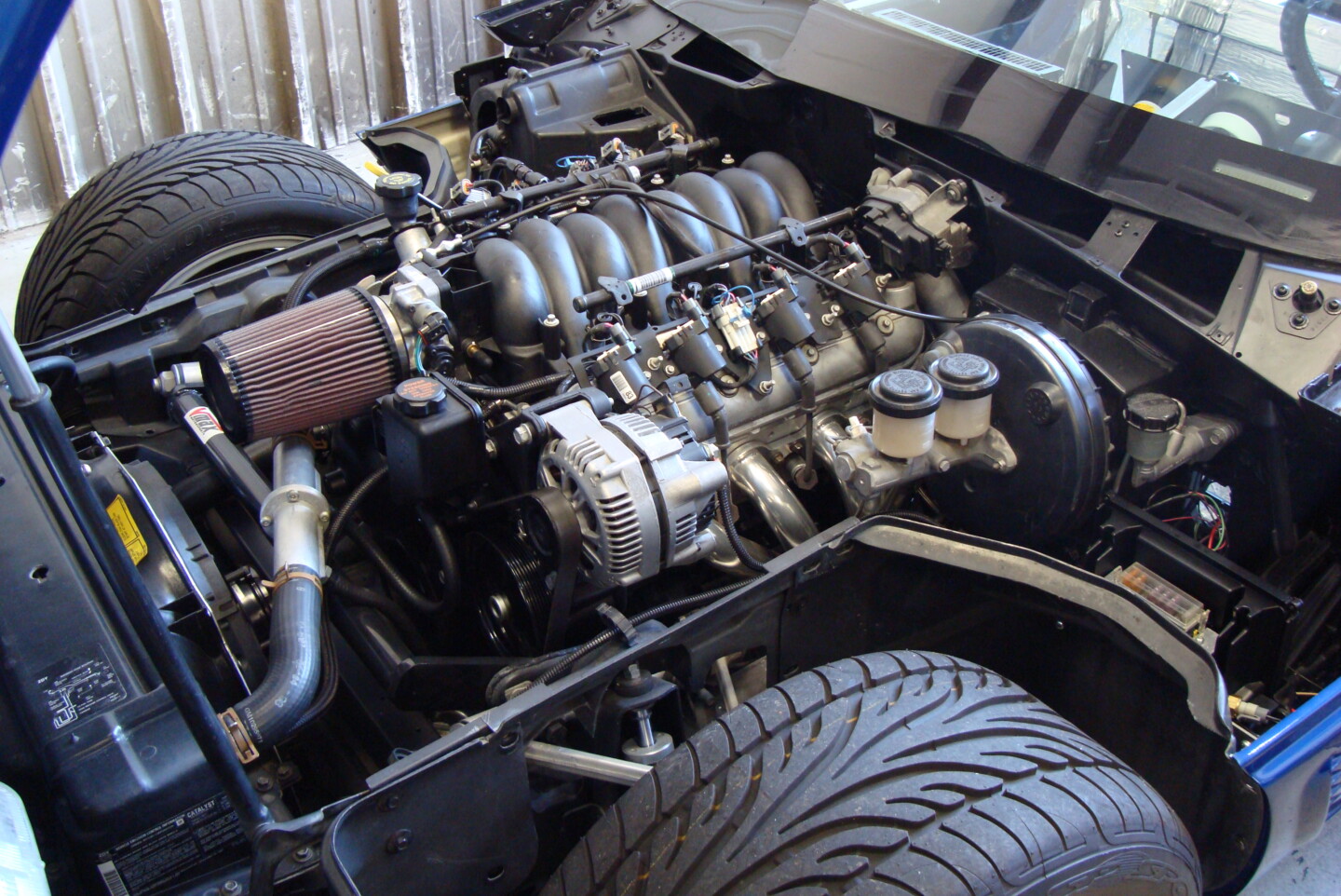

As the “LS Honcho” at Summit Racing Equipment, Brian Nutter has dealt with various modified Corvettes – both his own and those of customers. According to Nutter, “If you own a Corvette and are looking to increase your car’s power level, we have a large variety of LS engine components and packages that can provide just about any power level you want. That being said, more fuel is required whenever you make more horsepower. So we try to match components to the ECM’s ability to control them and recommend parts based on the engine combination and the behavior you are looking for.”

If you intend to drive your modified Corvette on the street, you have to reprogram the ECM, and if the car has an automatic trans, you may have to reprogram the TCM for good drivability and maximum performance. – David Nutter, Summit Racing Equipment

With a race car, a stand-alone aftermarket system may be the best choice, but if you intend to enjoy your Corvette while you drive to work or on weekend outings, reprogramming the original control modules is the only sensible choice. As Nutter points out, “A stand-alone system not powering the dash is one thing, but with the CAN bus system used in late model Corvettes, all the modules are interconnected. That means power door locks, windows, ABS, stability control, anti-theft, electric power steering, electric brake master cylinders, and PWM fuel pumps are ALL affected. Consequently, replacing the original ECM with an aftermarket version is not a viable option.”

When using an EFILive Flashscan or Autocal to record or monitor data, up to 10 parameters can be displayed on the screen. Pressing the down arrow cause the data to scroll, which brings any additional selected parameters into view.

No More Burning Chips

That’s where EFILive shines with the FlashScan system. As the name implies, FlashScan enables you to “flash” an ECM or TCM with new data and also allows you to scan and store operating data in real time. In computerese, “flashing” refers to the process of writing new data to an ECM or other types of control module. Back in the day, writing new data was referred to as “burning,” as in “burning a new chip.” However, beginning with the 1994 Corvettes, removable chips, which had to be erased with ultraviolet light and then reprogrammed by inserting them into a “burner,” were no longer used. Instead, they were replaced with permanently mounted memory chips that can be erased and “flashed” electronically through a vehicle’s diagnostic port.

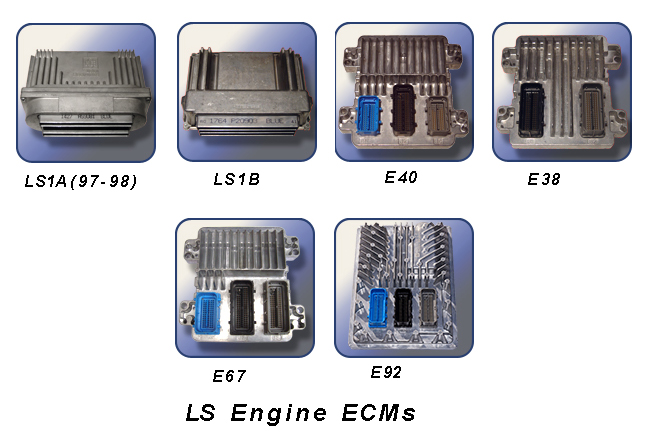

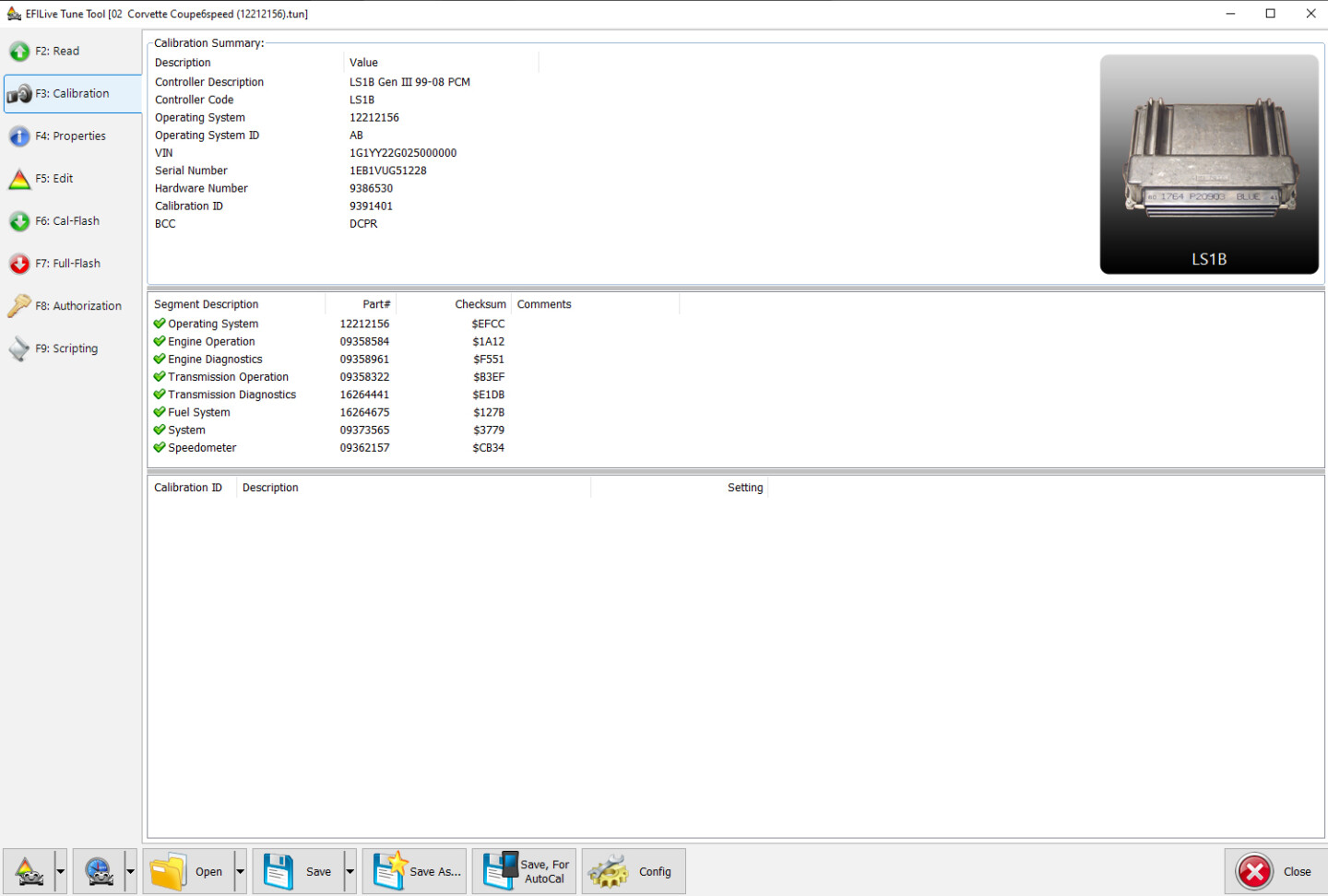

Since the introduction of the LS engine series in the 1997 Corvette, engine control modules (ECMs) have changed over the years, each ECM has a unique appearance, as shown in this photo.

With the introduction of the C5, electronic engine controls became significantly more sophisticated than they had been in the past. The PCMs used in the 1997-98 models are LS1A modules, and the 1999-2004 PCMs are LS1Bs. Engines in 2006 models are controlled by an E40 ECM (used only one year), and 2007 through 2013 models rely on E38 ECMs. The E92 processor is in command in 2014 and later models, although 2019 is the last year that can be easily accessed for tuning.

Regardless of the ECM, TCM, or PCM model, a typical reflashing process begins with downloading the existing files. Next, changes are made to the calibration data, and the new calibration program is then stored on a laptop computer before flashing it into the ECM, TCM, or PCM.

When a computer is connected, real-time data can be displayed on a virtual dashboard. If the data is recorded, it can also be viewed later, and the gauges respond just as they did in real time. If data is logged on a Flashscan or Autocal, it can be downloaded to a laptop, and the EFILive virtual dash will operate just as it would if a laptop was connected when recording.

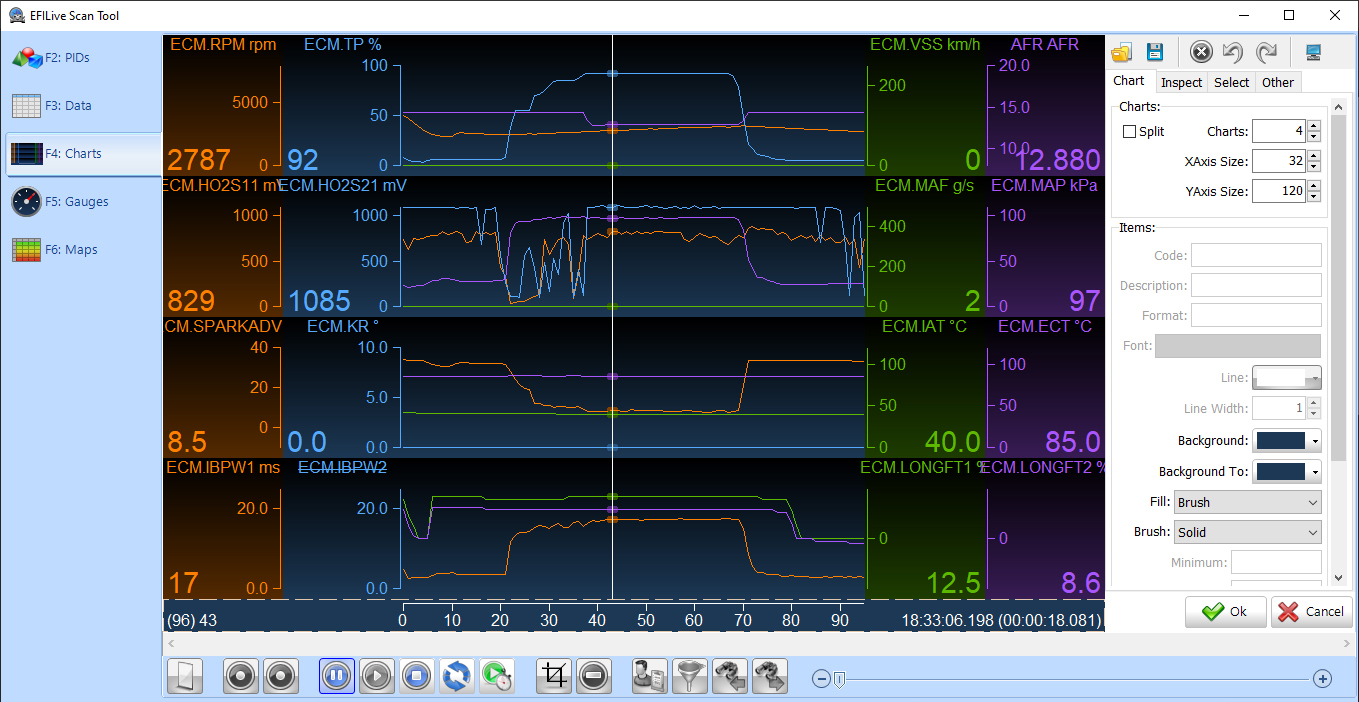

After reflashing, the next step should be a data logging session on the road or a dyno. The scan portion of FlashScan allows you to monitor and log data through a virtual dashboard and a chart (line graph). This is an essential part of the process because it tells you whether the new calibration is delivering the proper results. If you’re data logging while driving on the road, take an assistant with you to handle computer operations. Taking your eyes and attention off the road to look at a computer screen is a dangerous practice that can easily result in an accident.

Logged data can also be viewed in chart form, which makes analysis easier. As with virtual dashboard gauges, chart data is entirely customizable. Specific parameter IDs (PIDs) can be selected for each chart strip. Note that there is a line through “ECM.IBPW2 on the bottom chart strip. That’s because the PID for that particular data was not selected. In this photo, the numeric values displayed correspond to the cursor position, which shows a throttle opening of 92 percent at 2,787 rpm.

If the new calibration doesn’t provide the desired results, you can continue to make changes or go back to a previous file and make different modifications. For example, if the original stock file was stored, you can reflash the stock calibration and start again. A stock file also provides a reliable reference for checking many parameters because you know the stock calibration files have the correct data for a stock vehicle. Another reason to save a stock file is that it might be a time saver. If you’re starting with a file that you “inherited” and it’s way off the mark, starting with a stock file is often faster than working with an existing file from a tuner.

Data can be displayed for each calibration file. This information includes the type of ECM, vehicle VIN, operating system ID, and additional information about the file.

Unlike diesel engines which can pick up 75 to 100 horsepower with a mild tune, stock gasoline engines won’t pick up much power with a new “tune-up.” Modified engines are a different matter altogether. Any change in mechanical components that increases power output alters an engine’s airflow and fuel flow characteristics. A custom calibration (tune file) is then required to match the ECM’s response to the new flow characteristics.

After a 5.3-liter LS engine was installed in this C4, it was tuned with EFILive. The tuning operation required the creation of a custom calibration file. Several trouble codes had to be turned off because, among other things, the engine was connected to a manual transmission, not an automatic. EFILive software easily allowed all the necessary changes to be made.

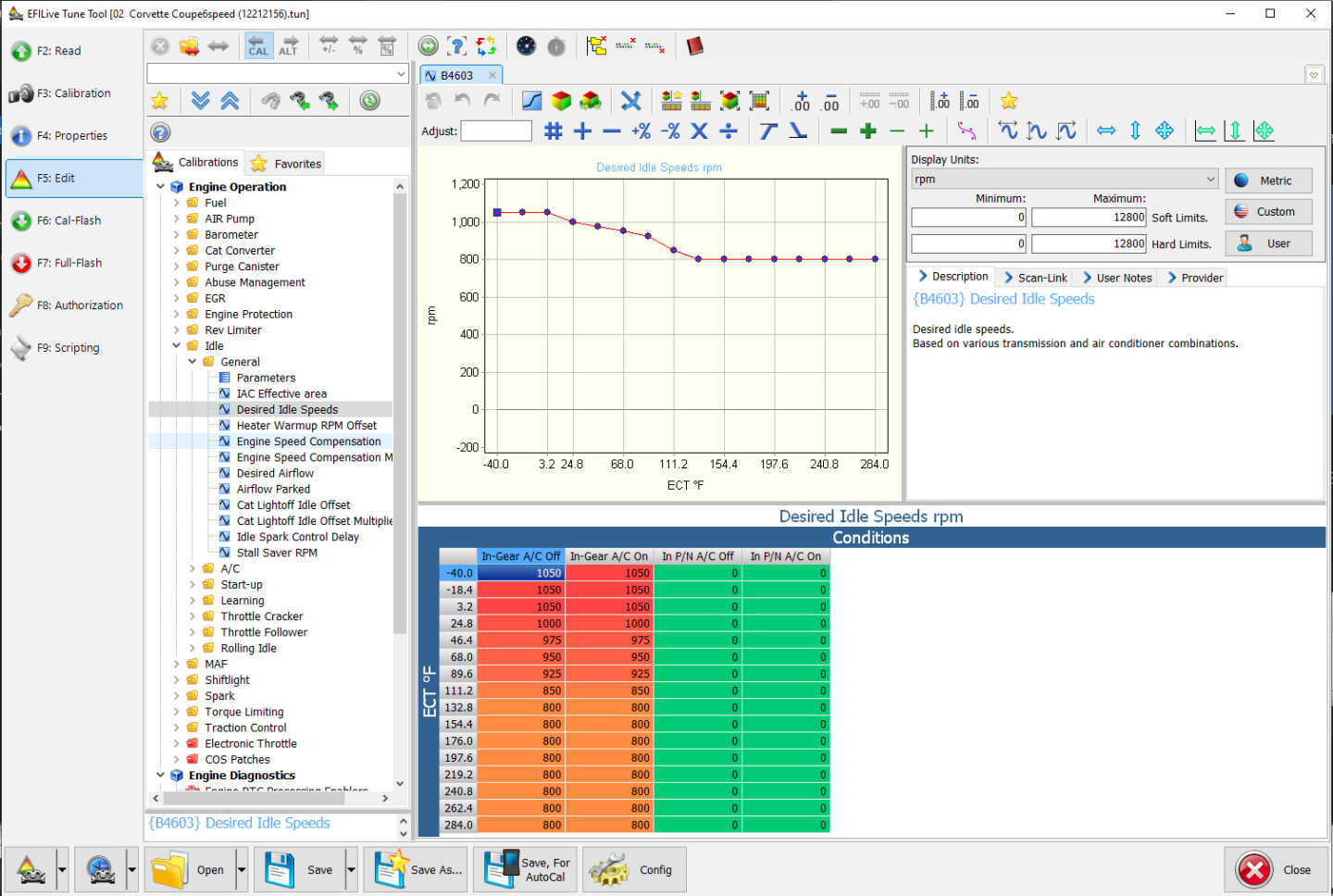

For example, after installing a camshaft with a significantly longer duration than a stock cam, an engine usually won’t idle reliably at the stock idle speed, typically between 575 and 800 rpm, depending on model year and transmission type. Some performance cams may tolerate stock idle speed, but idle air flow and timing may need to be altered for better idle quality and reliability.

The desired idle speed table is self-explanatory. This file is for a Corvette with a six-speed manual transmission, so idle speeds in park/neutral are irrelevant.

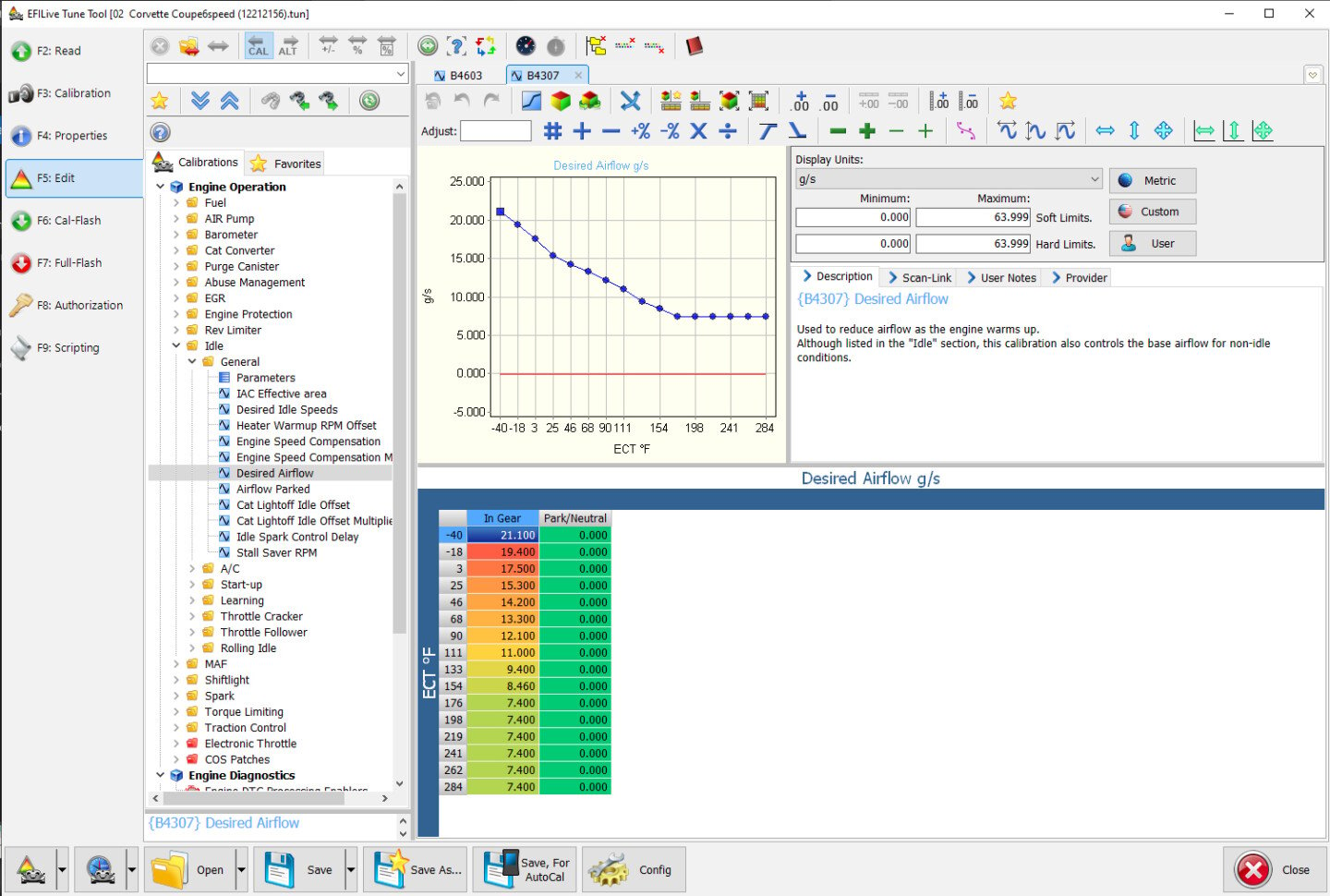

To streamline the tuning process, an ECM can be reflashed with a base calibration before the engine is started for the first time after modifications have been made. An example would be if a performance camshaft has been installed, raising idle speed is usually advisable and easily accomplished by changing the values in the “Desired Idle Speed” table. However, that’s only part of the solution. When idle speed is raised, idle air flow must also be increased, so values in the Minimum Idle Airflow table must be adjusted. If they aren’t, the system will hunt because the original commanded air flow isn’t necessarily compatible with the revised air flow rates required by the new cam.

The idle air flow table can cause problems if it’s ignored and desired idle speed has been changed or if a long-duration camshaft has been installed. If the specified air flow doesn’t closely match the required airflow, the system will hunt (ramp airflow up and down) in an attempt to achieve the desired idle speed. EFILive’s “RAFIG” parameter (in the scanning program) greatly simplifies the task of determining the airflow that will make the engine happy.

Many other variables can be adjusted before starting an engine after modifications. If injector size was changed, engine displacement was increased, and throttle body diameter was changed, values in the appropriate tables should be adjusted. Additional corrections with ported cylinder heads or exhaust system modifications may be required, but it’s most appropriate to make those adjustments after the engine runs.

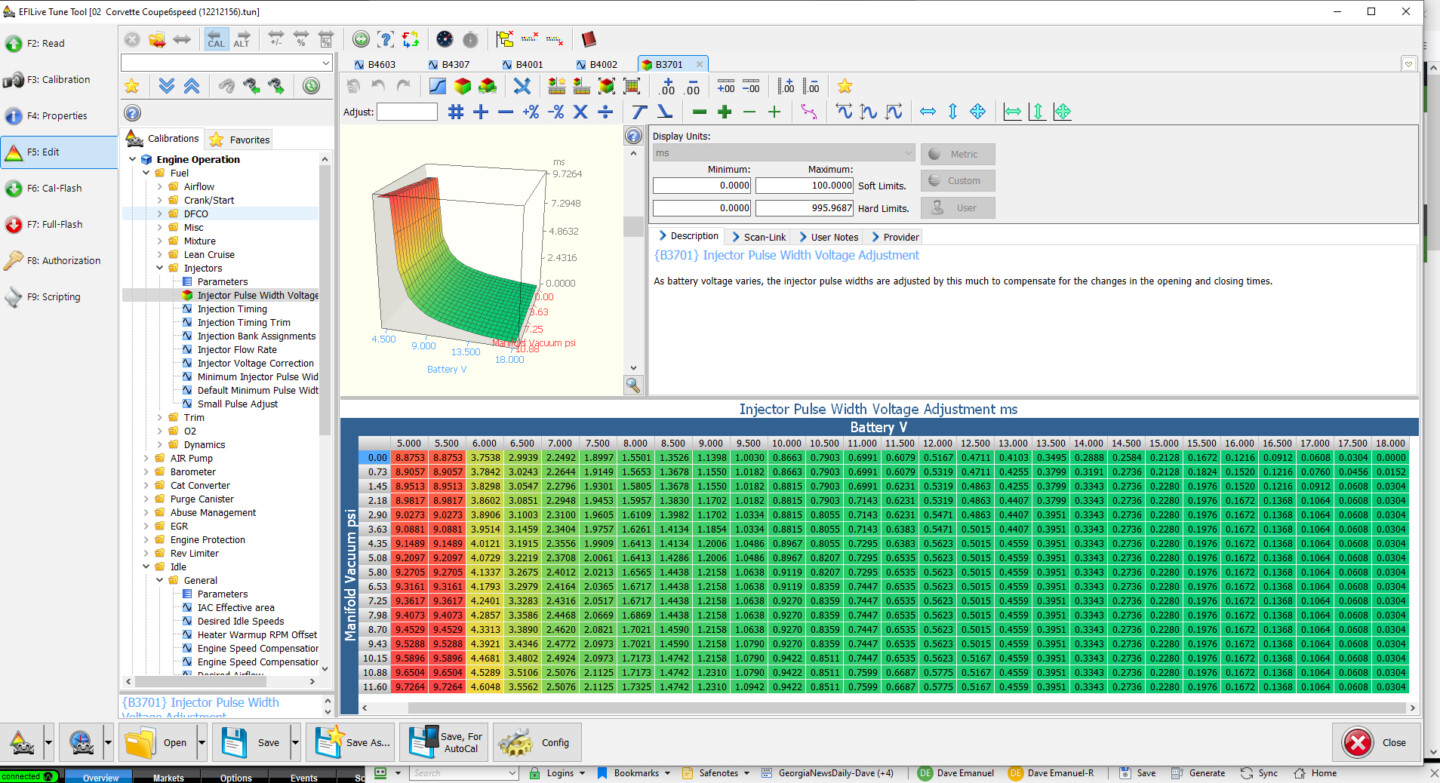

The injector pulse width adjustment table can cause problems when injectors are changed to a different type. Each brand/type of injector may require a different value that has been flow checked. Fuel trims can also be an issue if the voltage pulse width adjustments aren’t correct.

That’s when the scan portion of FlashScan software is especially valuable. The system’s virtual dashboard and graphing capabilities allow you to monitor various parameters and the amount of correction the ECM is making. Fuel flow is usually of particular interest, specifically if the injectors have been changed.

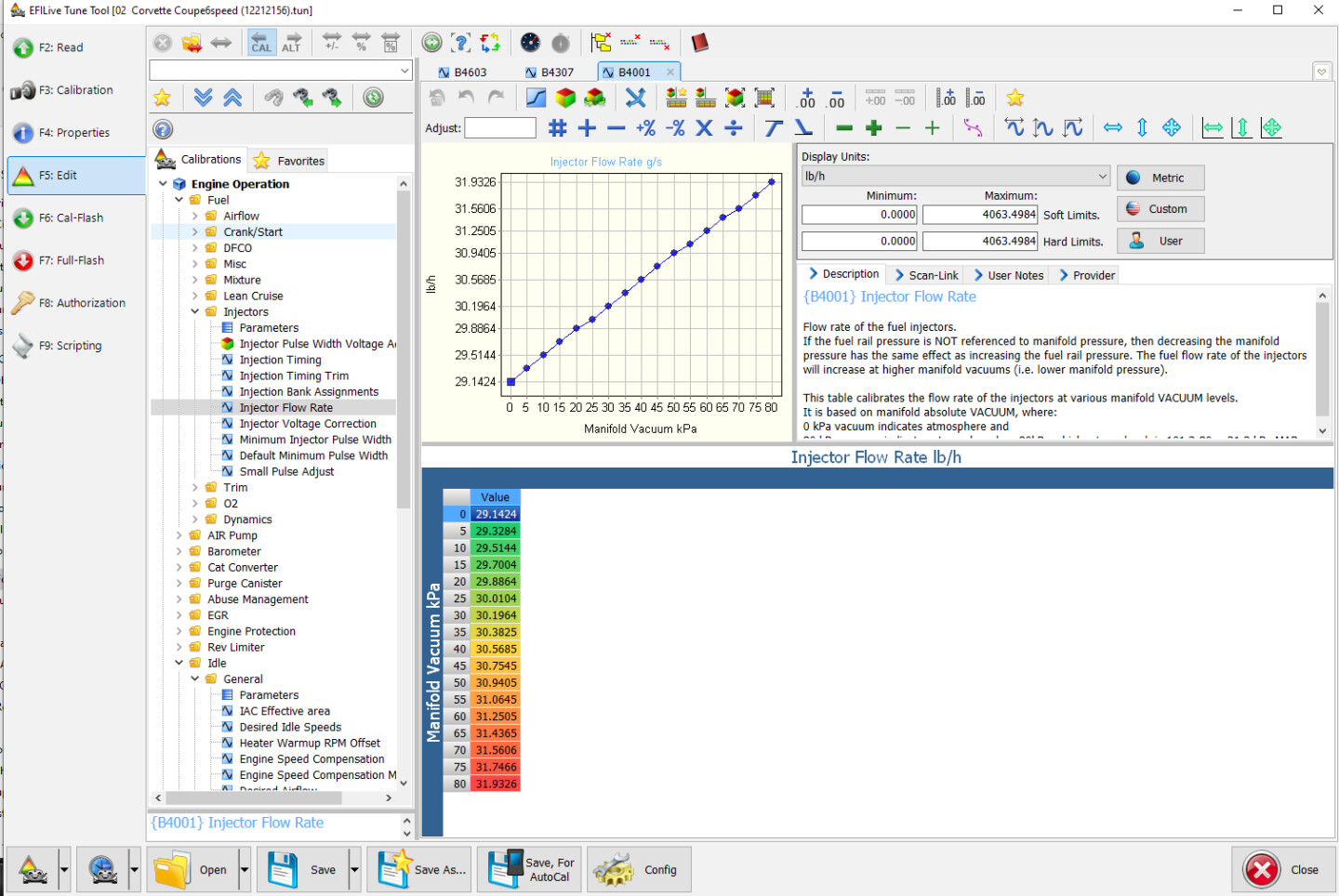

Injector flow rate is one parameter that requires attention when injectors or fuel system type is changed. This table shows a range of flow values necessitated by fuel systems that do not contain a mechanical pressure regulator.

Long-term fuel trim values show the percentage of fuel the ECM adds or subtracts during idle and part-throttle operation. These values are based on input from the front oxygen (O₂) sensors and relate to the changes made for the engine to operate at the commanded air-fuel ratio. Some systems automatically compensate for the percentage of ethanol in the fuel.

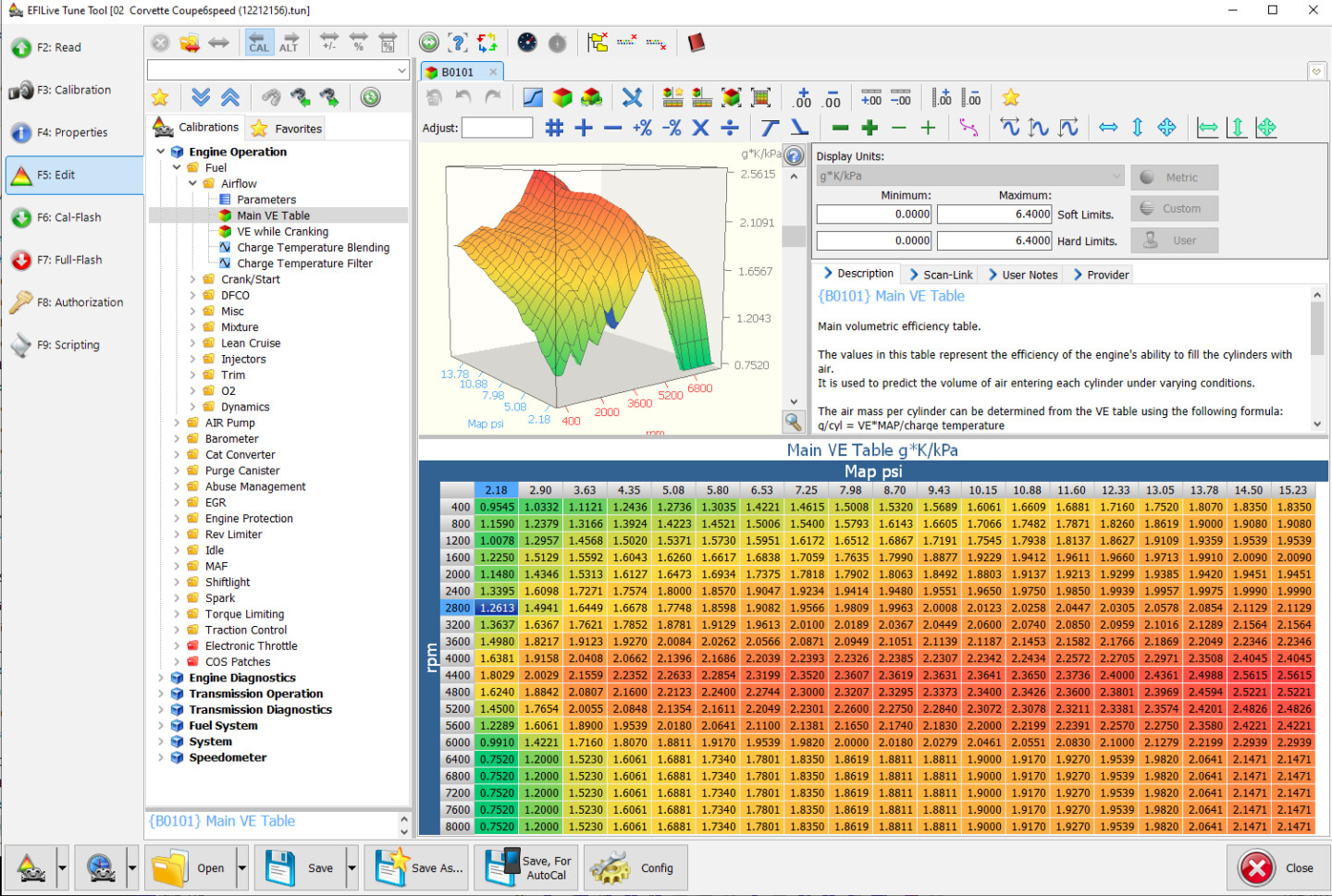

The VE table is essentially a fuel flow table as it estimates the volume of air entering an engine. The amount of air an engine is processing is the primary determinant of the amount of fuel it needs to achieve the proper air/fuel ratio. If the mountain terrain appearance of this graph is surprising, you may also be surprised that it is a stock VE table for a 2002 Z06.

Another point to consider is that values in the injector flow rate table are only one of the variables that an ECM uses to compute injector pulse width. Also relevant is the Injector Pulse Width Voltage Adjustment table, which tells the ECM the amount to adjust pulse width based on battery voltage. These values vary based on brand and type of injector. Consequently, if you have a set of flow-verified injectors, Long Term Fuel Trims can still reach maximum or minimum set points if the voltage correction values aren’t the same for the original set of injectors and the replacement set. If you’re confident in the accuracy of flow data for a set of injectors, but the long-term fuel trims are way off, work with the voltage adjustment table.

The OEM narrow-band oxygen sensors provide accurate information for part throttle air/fuel mixture tuning. However, these sensors lose resolution when fuel mixtures move away from stoichiometry. A wide-band oxygen sensor, such as the one from Innovate Motorsports, is essential when tuning wide-open throttle air-fuel ratios. Output from the Innovate unit can be fed directly into a Flashscan unit, and the data can be displayed on the Flashscan virtual dash or a graph.

When tuning to achieve proper fuel flow, start with idle and part throttle operation and get that right before moving on to wide-open throttle. The original narrow-band oxygen sensors are all you need to dial in fuel flow at part throttle. On the other hand, you’ll need a wide-band sensor to accurately monitor air/fuel ratios at wide-open throttle. This is because narrow-band oxygen sensors do not reliably report air/fuel ratios that are substantially richer or leaner than stoichiometry.

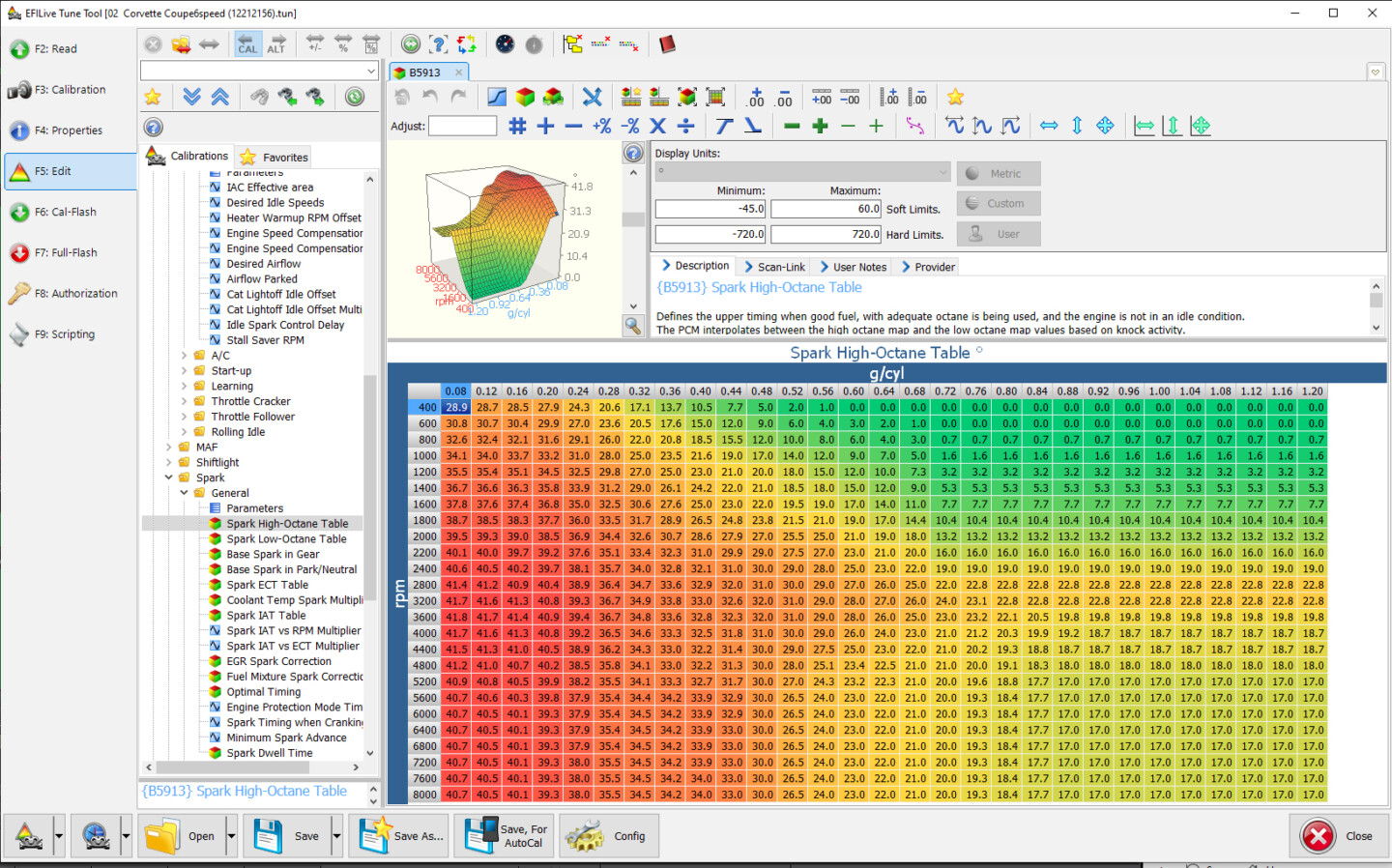

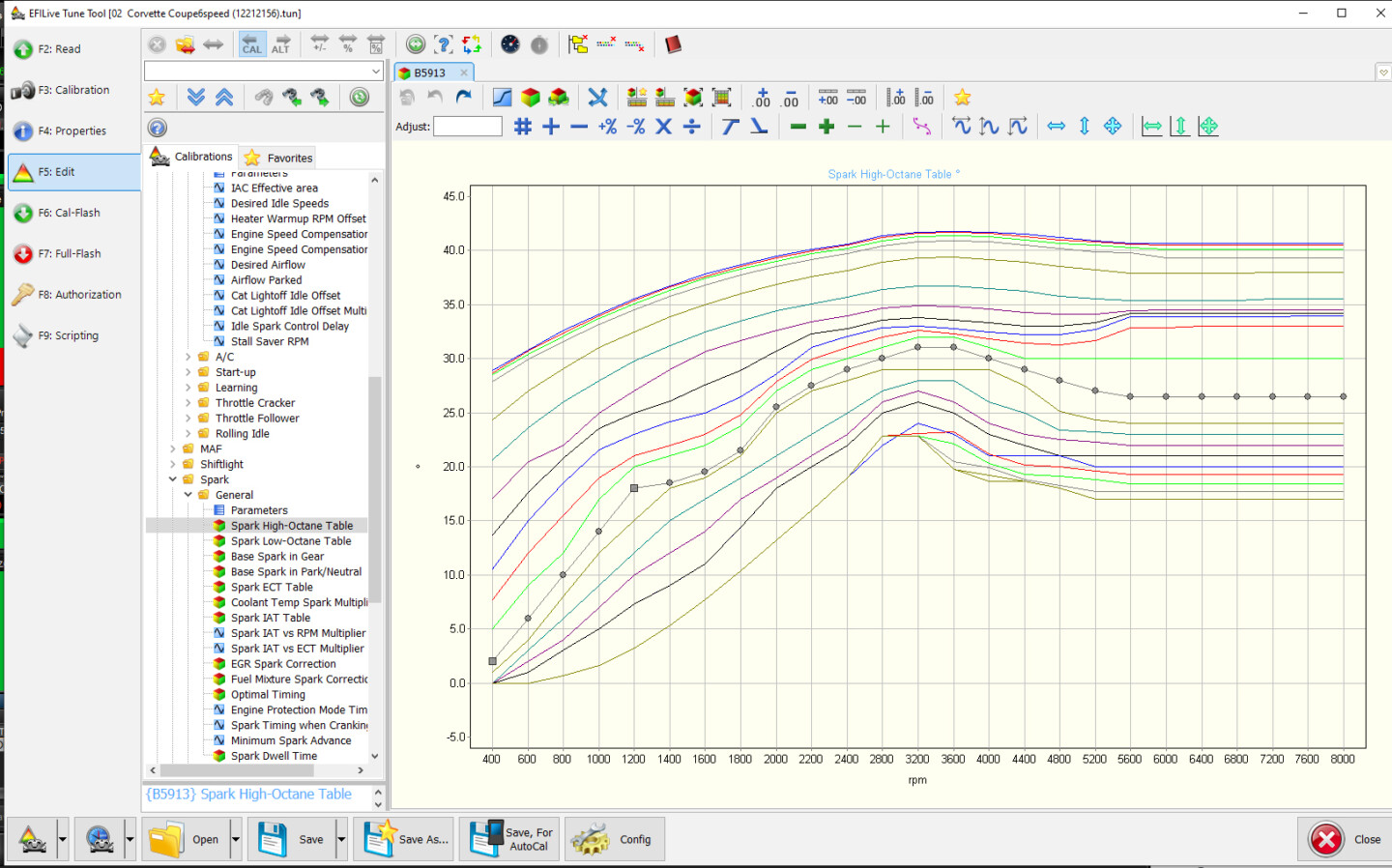

Spark values for both the high- and low-octane tables are plotted using engine RPM and engine load, expressed in grams of air being ingested per cylinder. Higher g/cyl numbers correspond to higher engine loads.

Ignition timing is another parameter that typically needs attention after engine modifications are made. Most engines with high-performance camshafts seem happier with more aggressive spark timing at idle. But the most critical consideration is making sure spark knock is minimal, especially at wide-open throttle. Therefore, it’s essential to do some data logging and monitor knock retard. Knock is most likely to occur when accelerating between two-thirds and full throttle in the upper gears. Knock will sometimes occur during throttle transitions but not at wide-open throttle. Consequently, it’s crucial to log data during various operating conditions.

Another option is to display a graph in a two-dimensional (2D) format rather than a three-dimensional one. 2D graphs make it easier to see profiles for each set of values. In this graph, each line corresponds to spark timing for given grams of air/cylinder value. Lines that have circles or squares on them can have data points moved by clicking and dragging.

One of the many advantages of EFILive’s FlashScan system is that the data logging portion is integrated with the tuning portion. When a data log is open, and an area of a graph is highlighted, the cells in the relevant tuning table are indicated. That greatly simplifies making the necessary changes to correct an undesirable operating condition.

EFILive has given a great deal of control to car enthusiasts that modify their vehicles by making the software and interface easy to navigate and use. With the FlashScan tool, you can fine-tune every aspect of your car’s calibration for the best performance and reliability possible.