Most individuals who work on their own performance vehicles can relate to the following frustrating scenario: You’ve saved your hard-earned money for high-performance parts, you’ve bloodied your knuckles during the installation, and then, when you go to loosen up one remaining bolt, it’s either stripped or, even worse, seized.

Stripped or seized exhaust bolts are a nightmare. Not only do these issues occur in the cramped spaces between the engine bay and the engine, but they can also affect critical components like the cylinder heads. If it’s an exhaust stud that has been stripped, leaving it unsecured isn’t an option, as it could lead to an exhaust leak, creating an unsafe condition in the cabin. So, what’s the solution to this problem? It’s simple: ARP exhaust bolts.

Disaster Strikes

When it comes to spending a little extra money on quality fasteners, typically around a dollar more per bolt, you know it’s worth every penny if you’ve ever lost an entire weekend trying to remove a rusted, seized OEM fastener. Manufacturers, in their quest to save money on millions of bolts, often opt for low-budget fasteners.

Unfortunately, for DIY enthusiasts like you and I, we’re the ones left struggling to remove these cheap fasteners while leaning over a fender in our driveway on a scorching hot day. Exhaust bolts, situated near the wheel wells, are constantly exposed to the elements and subjected to high levels of heat, along with an incredible number of heat cycles. This combination makes them susceptible to rust and deterioration.

This OEM bolt and nut did not want to separate from each other at the exhaust flange. I would have paid any amount of money to avoid this nightmare. After this little fiasco, using ARP bolts in the exhaust system makes a lot more sense.

No matter how much Liquid Wrench you apply to a bolt, how intensely you heat the cast-iron head, or how much ice you use on a bolt head, if the cheap bolt has deteriorated to a certain point, chances are you’ll end up breaking the head off. Congratulations! This project now necessitates drilling, tapping, trips to the hardware store, and a slew of other nightmarish tasks. All you wanted to do was remove an exhaust bolt.

ARP Origins

To avoid exhaust leaks, poisonous gases, and the need to drill into your engine, simply replace your low-cost OEM fasteners with ARP bolts. ARP, which stands for Automotive Racing Products, led the way in the early ‘70s by creating high-quality, U.S.-made fasteners. They employ a cold-rolled and cold-formed process that, at the molecular level, produces a forged and robust fastener. A bolt manufactured with heat may not be as strong as one created through cold forming. ARP also utilizes proprietary patented processes in their coating and manufacturing, which have paved the way for fasteners used in aerospace technology.

Using cold rolled ARP bolts ensures that your exhaust bolts will not fatigue and break causing you to lose hours upon hours with one bolt.

The journey for ARP began with one man, Gary Holzapfel, a racing enthusiast who noticed that many engine failures were attributed to poor fasteners failing under the stress of high RPM moments. Drawing from his background in building fasteners for aerospace applications, Gary brought that advanced technology to the world of racing. The rest, as they say, is history. According to Jarod Raschke, ARP’s tech support guru, what sets their products apart from the competition is where it all begins: the raw materials sourced from the best places in the USA, combined with a cold forging process, is what makes their products superior.

End The Exhausting Search

“When it comes to exhaust bolts, we recommend our stainless fasteners,” Raschke says. ARP promotes stainless steel for exhaust applications because it is resistant to corrosion, which is crucial for exhaust bolts exposed near wheel wells, where moisture can come into contact with the bolts. Additionally, stainless steel can withstand extreme heat.

“In the past, many people encountered issues with stainless steel causing thread galling,” Raschke explains. “However, thanks to ARP’s cold-forming process for threads on the stainless steel fasteners, this is no longer a problem. ARP’s stainless fasteners won’t gall the threads, and they outlast chrome-moly bolts, which are prone to rusting.”

Another advantage of using ARP exhaust bolts is the option to replace bolts with stud kits. These stud kits feature specially designed “nut starter” noses, making it much easier to accurately position gaskets and guide the header flanges into place. The compact design of these stud and nut kits also allows for easy access for socket wrenches in the tight proximity of header tubes. If you’ve ever found yourself lying on your back underneath a car, painstakingly turning header bolts one-sixteenth of a turn at a time with a wrench, then you understand the importance of being able to use a socket wrench.

The precision-made bolts from ARP are nominally rated at 180,000 psi, which is 20-percent stronger than Grade 8 fasteners. It’s this combination of high-quality source materials, exceptional strength, thoughtful design, and top-notch manufacturing from ARP that guarantees your exhaust bolts will fulfill their purpose — clamping your headers or exhaust manifold to your heads. This ensures that you never have to endure the annoyance of an exhaust leak or the smell of exhaust in your cab again.

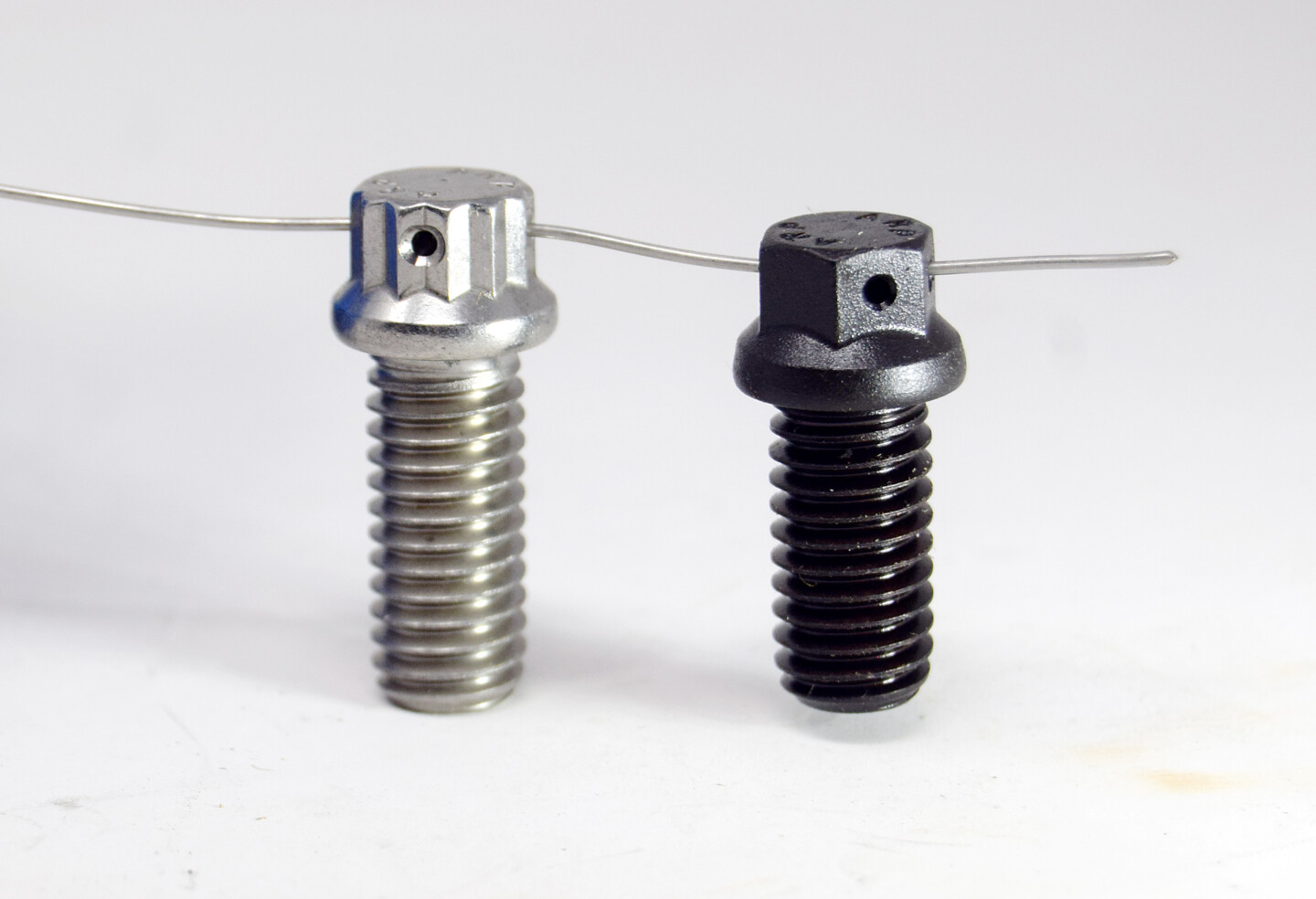

ARP also manufactures their exhaust bolts with a hole in the head of the bolt to add safety wiring to ensure the bolt does not go anywhere.

“Where ARP’s manufacturing process truly shines is in high-heat situations. When it comes to turbo attachment bolts or exhaust manifolds, where temperatures can soar, you absolutely need a top-quality fastener,” Raschke details. “Think about it this way – if you’re a manufacturer, you’re often looking to cut costs even if it’s just a few pennies on each bolt, especially when dealing with millions of them. However, in the world of racing, quality is paramount. You don’t want cheap, mass-produced bolts. Even if you only need 16 bolts for your headers, it’s worth investing a few extra dollars for peace of mind.” Solid advice indeed.

Learn From Our Mistakes

So, what have we learned today? Exhaust bolts get hot. Exhaust bolts are exposed to the elements and can rust. Factories often use the cheapest bolts to save a few pennies. But all of that can become your problem one day as you find yourself drilling out a broken bolt and re-tapping the threads on an engine.