Not that long ago, many drag racers solely used a charged battery to make a pass. Yes, the race car may complete a pass on battery juice alone, but anyone who has ever compared their overall performance with and without an alternator will tell you the difference is colossal.

Consider your capacitive discharge ignition (CDI) that converts your battery current to a high-voltage discharge (typically 400 to 500 volts primary voltage, plus a coil output of 40,000 to 60,000 volts at the spark plugs) — it’is easy to imagine why a battery cannot do this job alone.

Imagine Electricity As Water

You may know the old adage that electricity is like water flowing through a hose. Think of amperage as the size of the hose that the water flows through, voltage as equivalent to the pressure of the water flowing through the hose, and ohms as any resistance within the hose against the water.

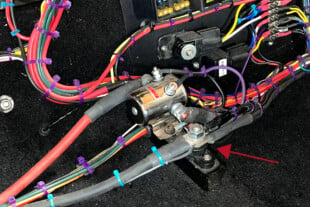

Have you ever seen a battery with only one post? Then your alternator requires a charging wire and a proper ground. The alternator bracket connected to the engine block is insufficient. All Powermaster alternators feature a dedicated grounding lug for good reason. They also specify using the same gauge ground wire as your lead wire for a proper circuit.

We spoke to Ed Law, Technical Specialist at Powermaster Performance, who added his insight to the hose/water analogy.

“The fundamentals of a direct current (DC) power system can be calculated with averages. Imagine your alternator as basically a water pump. It pumps electricity to your battery, which is a bucket (storage) for electricity. Your battery should function as a reserve. You do not want to drain your battery with more electric demand than an alternator supplies. Yet, you also do not want to continually overcharge your battery, which would be the equivalent of overfilling your bucket — this can damage your battery.”

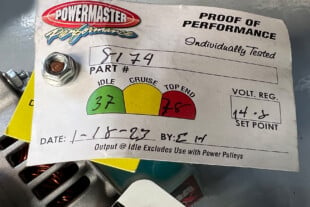

Out of the box, the alternator includes a Powermaster proof of performance tag from their extensive testing centers at the factory. With our alternator installed, the output at our battery matched their tag at 14.8 volts.

Volts Are Volts — Well…

Regarding 12- versus 16-volt DC systems, remember the aforementioned “bucket” analogy — with your batteries again being the bucket, your incoming charge voltage to the battery must be precisely matched to prevent damage.

Powermaster offers a number of mini and full-size alternators designed to output 12, 14, or 16 volts for properly charging different voltage batteries. Upstream power (your charging voltage and amperage to the battery) is critical, while the downstream circuit (from the battery) most times is not.

Downstream from your battery, most any pump or fan will happily operate on 12 to 16 volts; your DC-powered hardware does not care. That said, we cannot stress enough to “trust, but verify.”

Some 12-volt electronics may get damaged by a higher voltage. Still, most manufacturers design their product to function properly on 12 to 16 volts, have internal electronics to protect them from over-voltage, or on rare occasions, must have a voltage drop device installed.

“We use very precise regulators to achieve a proper charge,” Law explains. “All of our regulators, including the Powermaster XS Volt design, come out of the factory set at 14.8 volts. Adding up the amperage demand of your specific application is critical so as not to under- or over-charge whatever batteries you use.”

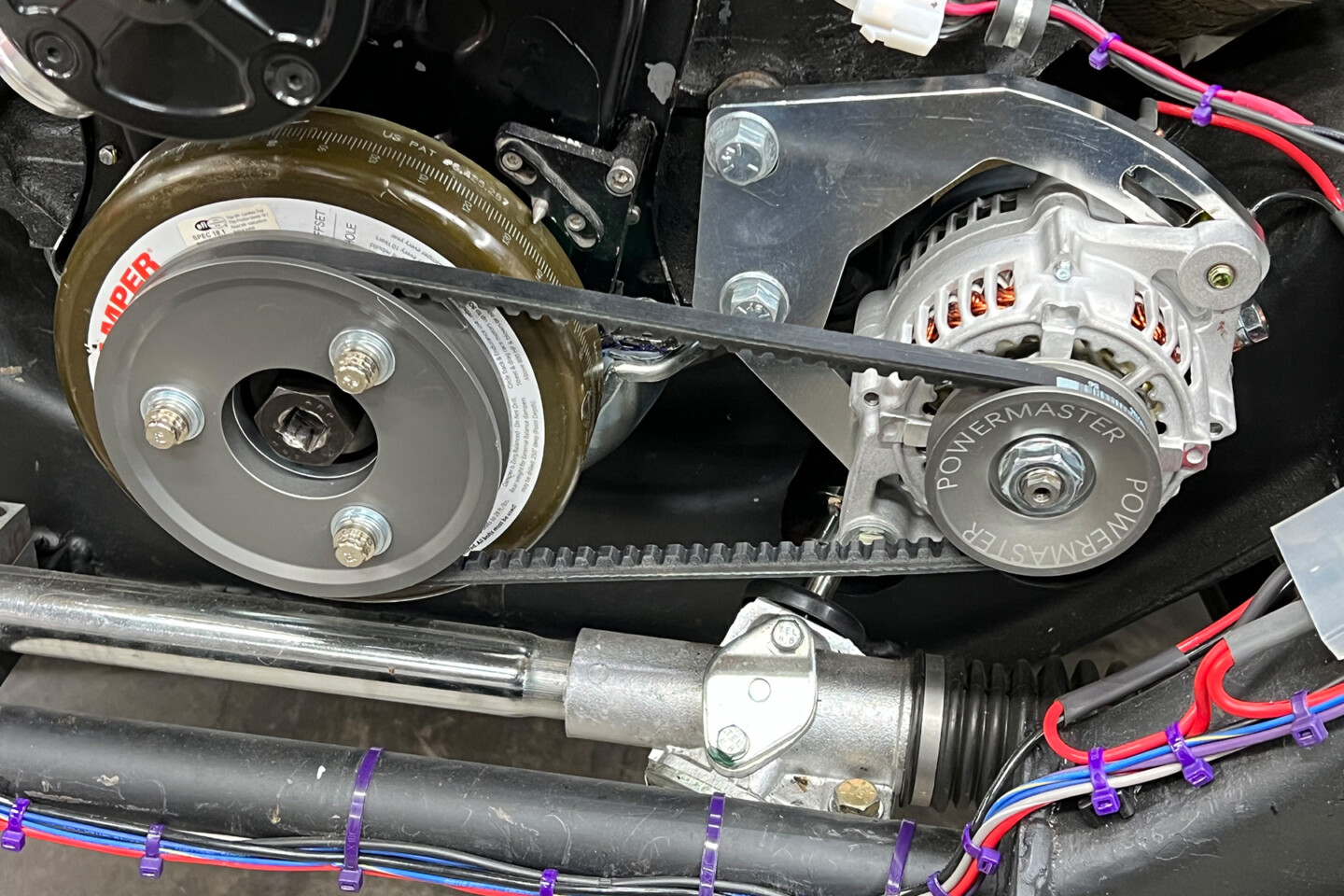

The advantage of the mini Denso alternator assembly is its capability to mount low on our big-block engine, yet clear the stock front subframe.

Adding Up DC Amperage Demand

As well as our ignition, a second major electrical-based system is our Camaro’s electronic fuel injection, which must also avoid diminished power. Experts have often said that problems with many EFI or digital ignitions can be traced back to insufficient voltage or bad grounding.

The Powermaster Alternator is wired directly to the trunk batteries using a heavy 6-gauge wire (arrow.) Also, every wire circuit, including the alternator, is grounded through a 2-gauge wire back to the batteries. No component is grounded to the chassis or body.

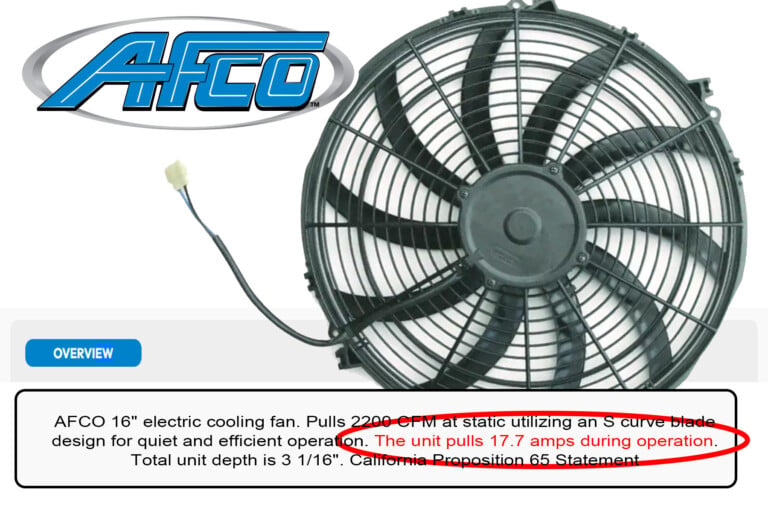

Your manufacturer’s instruction manuals from each electrical component should offer normal and sometimes peak amperage draw data. If not, directly ask the manufacturer or measure the amperage manually. We have seen many pumps and fans incurring sizable differences in the power draw between brands. With that, we summed up every wired component in our car, from headlights to taillights.

Adding Up Our Camaro's Total Amperage Draw

Headlights (LED bulbs) – 2.5 amps x 2

Radiator fans – 10.5 amps x 2

Transmission cooler fan – 6 amps

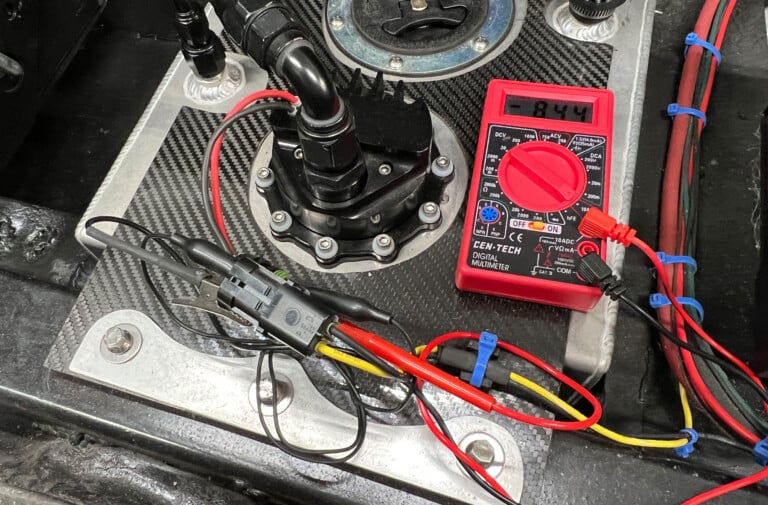

Electric water pump – 6 amps

Electronic gauges – negligible

Tachometer/data recorder – 2 amps

Dash instruments – .5 amps

Shift timer control – 1 amp

EFI injectors and control unit – 12 amps

CD ignition and coil – 8 amps

Brushless electric fuel pump – 8 amps

Taillights (LED bulbs) – .5 amps

Not Factored

Transmission brake solenoid – 18 amps (temporary draw)

Line lock solenoid – 8 amps (temporary draw)

Automated shift solenoid – 10 amps (temporary draw)

Starter – 500 amps (temporary draw)

———————————————————

Total continuous draw: 70 amps

“Your starter and solenoids are activated for a very short time,” Law says. “Where we first mentioned the bucket theory at the beginning of this article, the batteries will supply short-term power; then the alternator will easily help the batteries recover.

Specifying And Ordering An Alternator

Law also makes it a point to highlight pulley ratio.

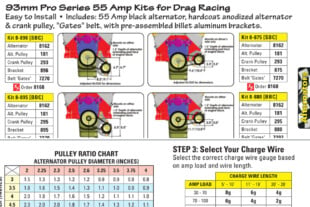

“This ratio between the crankshaft and alternator pulleys is very important. These are normal discussions we regularly have with enthusiasts. If you have an LS engine spinning at 8,000 rpm with OEM-style 3.47:1 pulley ratio, you will destroy any alternator, as the ratio will spin the alternator beyond its rated capability. We offer a wealth of pulley options, plus a ratio chart in our catalog to calculate your desired alternator shaft speed. Our typical idle amperage is measured at 2,400 rpm, and peak amperage tops out at about 7,000 rpm alternator shaft speed. So, anything more than 7,000 rpm, and you’re placing wear on the alternator. ”

When calculating the sum of your vehicle's amperage, never guess. You typically can find each component's amperage draw within the manufacturer's instructions. You can also use a multimeter wired in line with the positive feed of a circuit to get an absolute number.

Our big-block Camaro will have a peak engine RPM in the 7,000 rpm range. With a 5.3-inch diameter crank pulley and 2.8-inch pulley at the alternator, our pulley ratio is 1.85:1. At idle, our alternator shaft will be spinning at around 1,600 rpm. The engine’s 7,000 rpm will turn our mini-alternator at just under 13,000 RPM, well within the suggested limit of 18,000 rpm.

The Unique Powermaster XS Volt Regulator

If an alternator did not have voltage regulation, as it spins faster, it would continue to produce ever-increasing voltage. The regulator has a preset point of maximum voltage output. With the internal regulator in the standard Powermaster alternators, you can order preset limits of 12-or 16-volt output.

The Powermaster XS Volt alternator option has a small built-in potentiometer that can adjust the regulator’s voltage from 13.5 to 18.5 volts. Charging-sensitive gel batteries at low voltages or using the hybrid 14-volt lithium battery is not a problem. One XS Volt alternator will work with your car no matter what battery you choose.

We compared our new Powermaster to an old GM-style alternator on a scale. Not only can we now handle our 70 amp load from all of our "gadgets," we saved over 12 pounds, as well. (Right) The crankshaft drive pulley uses a concentric ring to mate to our ATI Super Damper perfectly.

A switchable power-saving mode is another feature of the Powermaster XS Volt regulator. With a switched circuit to the internal regulator, you can lower the peak voltage output by a few amps on demand. This mode also lightens the horsepower drain on your racing engine at key moments.

An additional terminal is wired to a switched ground. When grounded, the regulator’s set point is temporarily dropped 1.25 volts. If your regulator is set at a typical 14.8-volts and this pin is switched to ground, this immediately reduces the horsepower drag as the alternator is now regulated down to 13.55 volts. A separate indicator light output can be wired to an XS Volt alternator to tell the driver which mode they are in.

With our new mini alternator, we ordered the Powermaster XS Volt option. Using a small screwdriver, you can adjust a small potentiometer within the regulator to set the voltage while the engine runs. Powermaster's website and catalog are filled with technical instruction and worksheets to calculate your overall race car amperage draw.

Stay Ahead Of Your Amperage Demand

Every new component you add or update may contribute to the draw on your electrical system. It is easy to underestimate the amperage-hungry demand on your system if you don’t analyze your long list of electrically powered gadgets.

Along with Powermaster Performance’s extensive lines of OEM-style and performance-oriented alternators, they also have developed this distinct line of small, lightweight alternators, all with racing demands in mind.

With the XS Volt adjustment option, you can continually match the output of your alternator to your electrical demand and any new battery technology that comes along the way.

One Alternator, Many Features

“Big things in small packages” is a highly sought-after quality in motorsports. Additional perks like the adjustable voltage and an on-demand power cut feature continue to lengthen the benefits of the Powermaster XS Volt alternator. Get the “juice” to feed the long list of hungry electronics that continue to expand within your race car.