Forced induction has taken over the world of street muscle. Without a turbo, supercharger, or nitrous, it seems like your project is simply not complete. The bad news is in extreme applications, this puts more strain than ever before on your engine — especially the head gaskets.

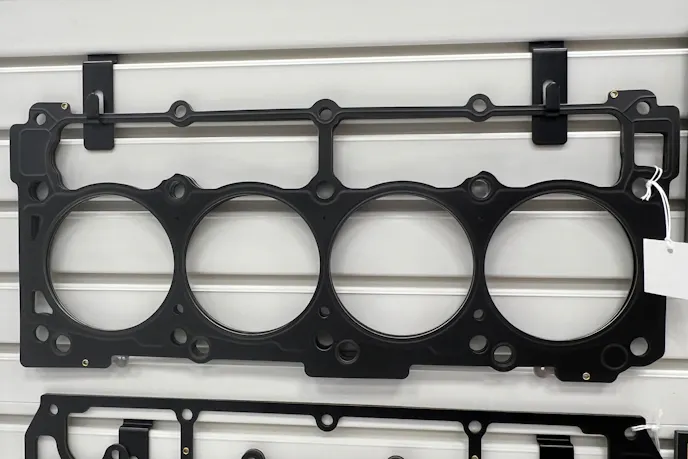

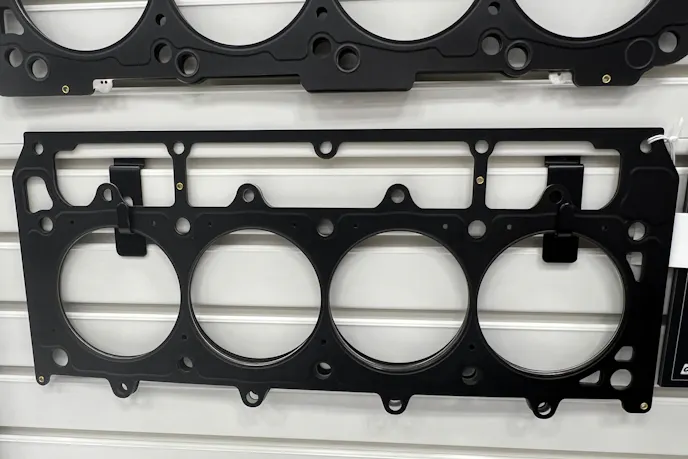

The good news is that Cometic Gasket has addressed this problem head on (pun fully intended). At the 2025 PRI Show in Indianapolis, Cometic showed its new Dual Stopper Technology (DST) gaskets specifically engineered for extreme applications. It is the next evolution of its proven Multi-Layer Steel and MLX Stopper designs. DST combines dual integrated, precision folded stainless steel stopper layers with its embossed, proprietary-coated sealing layers.

According to Cometic, this construction delivers a uniform, evenly distributed clamping force across both the cylinder head and block combustion seal, significantly reducing bore distortion and enhancing overall sealing reliability.

The gaskets are a seven-layer design available in .063- and .071-inch thicknesses.

“It’s going to be good for your drag and drive, forced induction, no prep, high-horsepower, 1,500-plus horsepower [applications] all day,” according to Brendan Chess, an automotive product manager at Cometic. “It’s your last bolt-on solution before you go O-ring, receiver groove, copper gasket. We mostly offer it in late-model stuff right now — Gen 3 HEMI, LS, LT six bolt. It’s mostly going to be tailored to late model stuff.”

He added, “The cool thing about this is when we build our Gen 3 HEMI gasket it’s going to work on the brand-new Dart block, and work on every single Gen 3 compatible head, so 6.1, 6.4, and Hellcat. Our LS is [compatible with] four-bolt and six-bolts, and it’s going to be ready to go with ½-inch head studs, as well as our Gen 3 HEMI and our LT and LTX. It’s configured to work with six-bolt LTR blocks. It’s configured to work on pretty much all the blocks and heads.”

The only exception at the moment is sleeved blocks, like RHS block, but as of right now it works with any factory block and any Dart block

Eventually, the company’s plan is to expand this type of gasket into the Coyote engine family, as well.

You might also like

Dart GTS 383: A Rare Cruiser For a Hardcore Drag Racer

Horsepower was up to 330, but fewer than 1,300 Dart hardtops and only 63 convertibles were sold in ‘69. The 340 was a more popular choice.