Ethanol is a Great Fuel – But You Have To Be Aware Of The Pitfalls

Words And Photos: Jeff Smith

This is a great time to be a car guy. Dodge just raised the ante with the 707 horsepower Hellcat 6.2L hemi and 500 horsepower is becoming commonplace so it’s never been easier to build horsepower. If you’re not packin’ at least five large under the hood, you’re probably not going to be offered a reserved seat at the bench racing table. But these are also uncertain times. There have been huge changes in the last decade in both the fuel and oil we pour into our high performance engines. It could be safe to say that gasoline isn’t what it was even 5 years ago. Most pump gasolines across the country contain roughly 10 percent ethanol (grain alcohol) and there is a movement in our nation’s capital to push this to E15 – or 15 percent ethanol for certain newer vehicles. This oxygen-bearing fuel is increasingly used as an octane booster because it is a renewable resource and is much safer than previously –employed octane boosters/carcinogens such as MMT (Methylcyclopentadienyl manganese tricarbonyl). As an interesting factoid, even NASCAR has gone green – literally with Sunoco’s NASCAR green-colored E15 fuel.

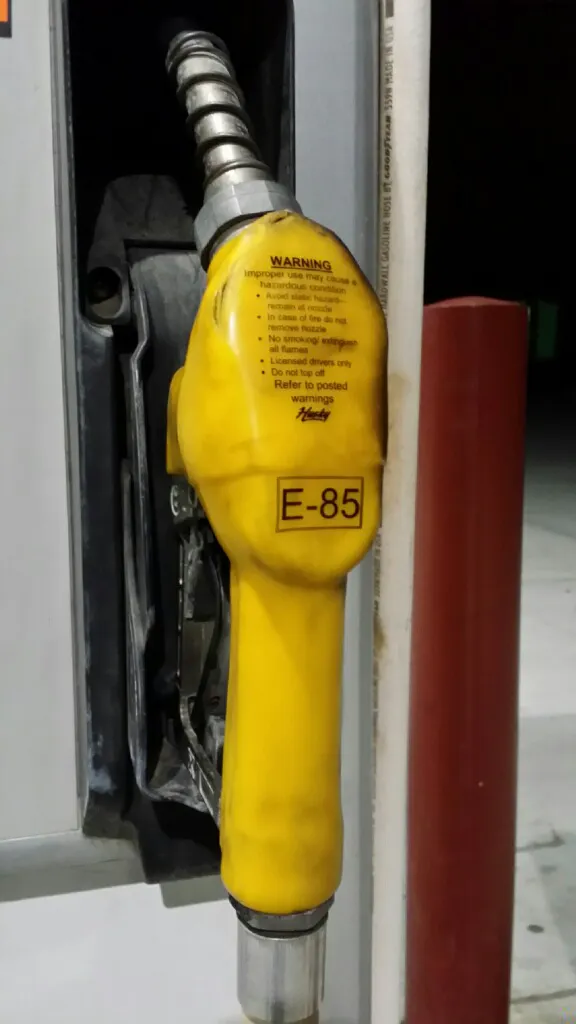

Reversing the percentages, E85 has become a positive option even for daily-driven performance street engines with its 105 octane rating. This fuel is finding increasing support among supercharged and turbocharged engine fans because of the fuel’s excellent inlet cooling capabilities. But these alcohol-based fuels also present engine lubrication challenges that is only recently been discovered. Earlier this year, a pair of lubrication researchers – Henara Costa from Brazil (where E20 is the predominant passenger car fuel) and Hugh Spikes of the Imperial College of London presented a research paper to a group of oil engineers, known as tribologists, that reveals a measurable link between small percentages of ethanol in the oil and a significant loss of performance of lubricating oil.

Driven Oil’s Lake Speed, Jr. attended this conference and we had a chance to speak with him about a few of the important conclusions from the presentation that revealed that even small traces of ethanol present in engine oil can cause increased engine wear. A good place to start would be to cover how ethanol finds its way into the engine oil in the first place. Assuming no direct leak path between the fuel system and the crankcase, the piston rings are the only seal between the combustion space and the engine’s oil sump. If you’ve ever been to an NHRA drag race and watched the Top Fuel and Funny Car crews perform between-round maintenance, then you’ve probably seen the dark yellow-stained oil that is heavily diluted with nitromethane fuel. Granted, this is an excessive dilution example, but it points to the fact that all engines suffer from fuel dilution of the oil.

In terms of street engines, most gasoline pumps in the United States are roughly 10 percent ethanol. But even at this small percentage, it is possible to see as much as a 5 percent by weight of ethanol in the oil. The Costa and Spikes report reveals that measuring 3 to 5 percent fuel dilution in the oil is not unusual. Because all engines require a rich air-fuel (A/F) ratio during cold start and run conditions in order to maintain stable performance, this is where it is possible with wider clearances to allow raw fuel into the crankcase. EFI engines have much finer control over this so they can run leaner but even with EFI, fuel dilution in the oil is an issue every time the engine experiences a cold start situation.

This fuel/ethanol dilution issue is even worse with carbureted engines. Carbureted street engines often run rich even at normal operating temperatures. Add the variable of limited use engines like drag race engines or custom cars that are trailered to shows where the engine is operated for only a very short period of time and this diluted fuel and alcohol will be guaranteed to remain in the oil because the engine oil temperature never reaches the minimum temperature necessary to evaporate these impurities.

At sea level, ethanol begins to boil at 176 degrees F and is nearly completely a vapor at 190 degrees F. Water boils at 212 degrees F, so you can see that to eliminate the negative effects of alcohol in oil, it’s important to run the engine long enough to push the oil temperature up to a temperature higher than 212 degrees F. Gasoline is a complex hydrocarbon chain that has multiple boiling points. Its initial boiling point (IBP) is a relatively low 104 degrees F, with a high side that is well above 200 degrees F. This again reinforces the idea that in order to vaporize all these impurities, it’s important that engines achieve oil temperatures of at least 212 degrees F.

Drilling down to the finer details, the Costa-Stile report indicated that higher ethanol percentages approaching 10 percent can have serious negative effects including reducing the viscosity of the oil. This viscosity reduced reduces the film thickness of the oil that protects all wear surfaces – especially in high load areas such as the valvetrain and the rod and main bearings. Plus, the study shows that ethanol in the oil also delays the creation of film formation – which is that critical time where the oil creates a boundary layer between rotating metal parts when the engine first starts. What this means is that even a small percentage of ethanol in the fuel can increase the initial wear the engine experiences during cold start. This is important since as much as 70 percent of total engine wear occurs during cold start.

Essentially, ethanol acts much like a solvent poured into the oil and if you’ve ever washed parts in a solvent tank, you know how well that works at removing oil from metal parts. This invisible damage is what’s happening inside your engine.

Costa and Spikes also studied the effect of ethanol on anti-wear additives like ZDDP (Zinc dialyldithiophosphate). This additive has become a familiar engine oil additive for many enthusiasts because at roughly 1,200 to 1,500 ppm (parts-per-million) concentration in engine oil, this additive helps decrease wear especially for engines with performance flat tappet cams. ZDDP reduces engine wear by forming a contact layer directly on the metal wear surfaces through high pressure and load.

Unfortunately, the presence of ethanol in the oil can delay this transfer process. At the same time, the protective film layer produced by the ZDDP can be reduced because of competition from other additives such as dispersants and detergents commonly found in increasing concentrations in API-certified engine oil intended for use on the street. Add all these issues together and you can see how engine wear can be accelerated when even small concentrations of ethanol are present in engine oil.

A bad-case scenario would be a carbureted, pump gas show car that is only started and driven in and out of its trailer or entering and exiting the show. The engine never achieves any appreciable oil temperature because it is rarely driven more than a few city blocks. This engine would be a prime candidate for cold-start wear issues. It is important to note that the Costa and Spikes report evaluated a 5 percent concentration of ethanol in the oil. Given the above scenario, that 5 percent likely could occur.

Worse yet, this same 5 percent ethanol dilution could easily be possible with a carbureted engine burning E85 fuel. Engines running E85 must use between 20 and 30 percent more fuel (compared to straight gasoline) in order to make the same amount of power due to E85’s lower energy content. Because of this, E85-fueled engines must run at far richer air-fuel mixtures than gasoline and proportionately richer during cold-start conditions. As an example, a typical E85 engine idles at between 8.5:1 and 9:1 while WOT ratios hover around 7.5:1. Given these ratios, ethanol oil dilution should be a major concern.

So what can the average enthusiast do to avoid this accelerated engine wear threat? Acknowledging this problem is an outstanding first step. The best and easiest way to reduce ethanol dilution would be simply to operate the engine long enough and under sufficient load to generate an engine oil sump temperature in excess of 212 degrees F. Merely idling an engine until the water temperature reaches 212 degrees does not guarantee that the engine oil temperature is anywhere near that high. Conversely, if the engine experiences a significant load, the oil temperatures can quickly exceed 225 degrees F. This means coolant temperature is not a good indicator of actual engine oil temperature. This will demand an engine oil temperature gauge – or at the very least testing sump temperature with an infrared temp gun.

Another simple way to prevent potential engine wear from fuel dilution is to change the oil more often. This isn’t a big issue if the engine is street driven on a semi-regular basis. For engines that will be stored for long periods of time, the best plan is to change the oil and filter and then operate the engine up to a minimum oil temperature of 212 degrees F before final storage. This places fresh oil throughout the engine and minimizes the presence of water, acids and alcohols in the oil and offers the best protection for the engine bearings and other internal machined surfaces.

In the performance world, power will always be king, but you also have to pay attention to the details if you want that engine to live a long and powerful life. Ensuring the oil has a chance to do its job is a big step in that direction.

Sources

COMP Cams

compcams.com

Driven Racing Oil

drivenracingoil.com

M/E Wagner Performance

mewagner.com

You might also like

Put Modern Back In Your Mustang With Dakota Digital RTX Gauges

Dakota Digital has no less than eight gauge clusters for ’79-’93 Mustangs, which means there is no reason to live with the factory offerings