Formula 1 racing is easily the most expensive form of motorsports there is on this planet – the intricate, high-end materials used within the cars and the level of preparation it takes to make them competitive are nothing short of incredible. We found this awesome four-video series from the Infiniti Red Bull Racing team and just had to share, as we found the footage well worth the time to watch.

Formula 1 racing is easily the most expensive form of motorsports there is on this planet – the intricate, high-end materials used within the cars and the level of preparation it takes to make them competitive are nothing short of incredible. We found this awesome four-video series from the Infiniti Red Bull Racing team and just had to share, as we found the footage well worth the time to watch.

Team drivers Sebastian Vettel and Mark Webber have been unstoppable over the last several seasons, with Vettel earning the series championship in 2010, 2011 and 2012 – and he holds the points lead by a wide margin in 2013 with 9 wins in 15 starts so far this year.

In order to achieve that level of greatness, as we find out in the videos, it needs to start at the beginning of the program, in the R&D departments. In order to get an Infiniti Red Bull F1 racer onto the track, the process begins at the drawing board. Using supercomputers, the aerodynamics engineers work in 3D on a CAD program while the chassis designers sketch out the design by hand to come up with the most aerodynamic, stable racecar they can produce.

Each step of the process is quantified, either by the use of advanced computer programs like Computational Flow Development or the old-school way – building the part and putting it in the wind tunnel. Each of the results are analyzed to decide whether they make it to production and subsequently used on the car in a Formula 1 event.

They build new cars for each season over a five-month development process, with thousands of parts heading to the wind tunnel each week during the development phase. Remember where we mentioned that they quantify each part they develop? That’s done through the use of telemetry during the wind tunnel sessions, with over 400 lines of telemetry measured during the tests.

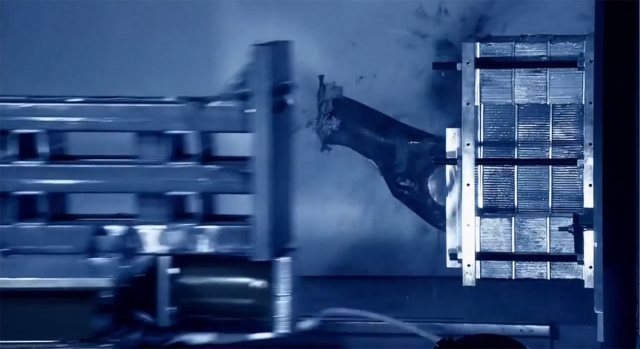

There can be thousands of design changes throughout the season based on what they learn, and the testing process continues with different rigs working 15 hours a day to test individual components.

Testing simulations stress different components to three or four times their expected lifespan, and there is a great emphasis on safety and reliability.

As you might imagine, much of the car is built from composite materials, chief among them the use of carbon-fiber, which has been in use since 1981 and has given perhaps the greatest improvements in performance and technology of any advancement within the sport of Formula 1.

Carbon fiber has ten times the strength of steel with half the weight, which is paramount to its performance. According to RBR’s Technical Partnership Manager Alan Peasland, “Composite bodywork is quite a complex and labor-intensive process, but it’s a process that we’re prepared to go to to make bodywork for the car.”

Each pattern is created in-house to manufacture the bodywork pieces from prior to being vacuum-sealed to compress the layers and put into an autoclave to pressure-cook and finalize their appearance and shape. It can take three days to make a single component from start to finish. There are even carbon composites used within the gearbox.

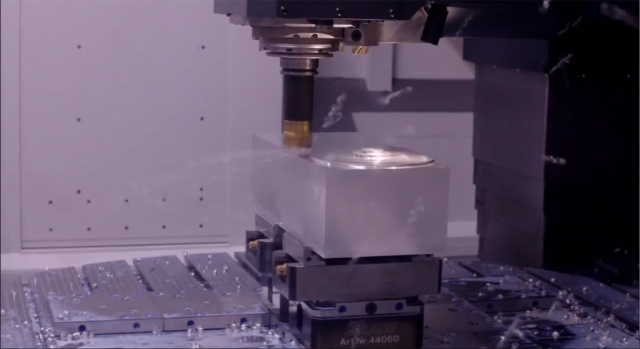

Manufacturing is another area where the Formula 1 teams like Infiniti Red Bull Racing have found great gains. By manufacturing 70 percent of the 100,000 components in-house, they are able to keep the tightest standards through the use of CMM (Coordinate Measuring Machine) to ensure that each part is built exactly as required, every single time.

The Red Bull Racing team has 20 CNC machines to achieve this goal – with the requisite operators to run them. There goes that cost thing again – each one of those machines can cost hundreds of thousands of dollar is not more, and the operator to run each one draws a hefty salary as well. Over 300 designers, aerodynamicists, and machinists worked on the construction of the RB9 chassis – the best in the business, building the best road-race cars in the business.

Formula 1 racing is not for the meek of heart – or wallet, as we discover in this series of videos. Hopefully you’ve enjoyed the look into the inner workings of Infiniti Red Bull Racing as much as we have.