For the better part of three decades, Mustang fans with manual transmissions relied on a top loader style arrangement for banging gears. The T5, and its venerable replacements that followed, used a shifter mounted at the rear of the transmission (tailshaft) that provided a direct connection between the shift lever and the shifting rails inside the transmission. With no linkages or other parts in the way, ripping through the gears via the shift handle was a direct action on the transmission itself.

For the better part of three decades, Mustang fans with manual transmissions relied on a top loader style arrangement for banging gears. The T5, and its venerable replacements that followed, used a shifter mounted at the rear of the transmission (tailshaft) that provided a direct connection between the shift lever and the shifting rails inside the transmission. With no linkages or other parts in the way, ripping through the gears via the shift handle was a direct action on the transmission itself.

A variety of much needed changes to the Mustang were made in 2005 with the all new S197 platform. Its retro styling, and improved chassis, also brought about a dramatic change in how cogs are swapped. Remote shifters, which rely on a support arm, and a shifting arm that connects to the shift rail on the transmission represented a major change in shifter arrangement and operation, and they continue to be a part of the Mustang landscape in the all-new S550 platform.

Mustang enthusiasts have been switching out their manual shifters since the 1960s, and today is no different. A good aftermarket shifter can provide better reliability in spirited driving situations and inspires confidence on the street or at the track. To help us shift Project 5-Liter-Eater better, we turned to MGW Shifters for its new Race Spec shifter.

The stock shifter is adequate if you are the kind of person who views your car as an appliance. In our case, with just over 5,000 miles on the odometer, we already noticed wear in the bushings which resulted in play in the shifter. Our stock shifter is pictured here with a Roush Performance shift knob installed.

Remote Pain

Ford has made considerable improvements to the OEM remote shifter arrangement since its introduction in 2005. The 2015 Mustang benefits from what we feel is the best stock shifter of the last decade. Its positive click-click motion is satisfying and there is none of the noise, vibration, or harshness transmitted through the shifter found in 1982-2004 models with a tailshaft-mounted shifter.

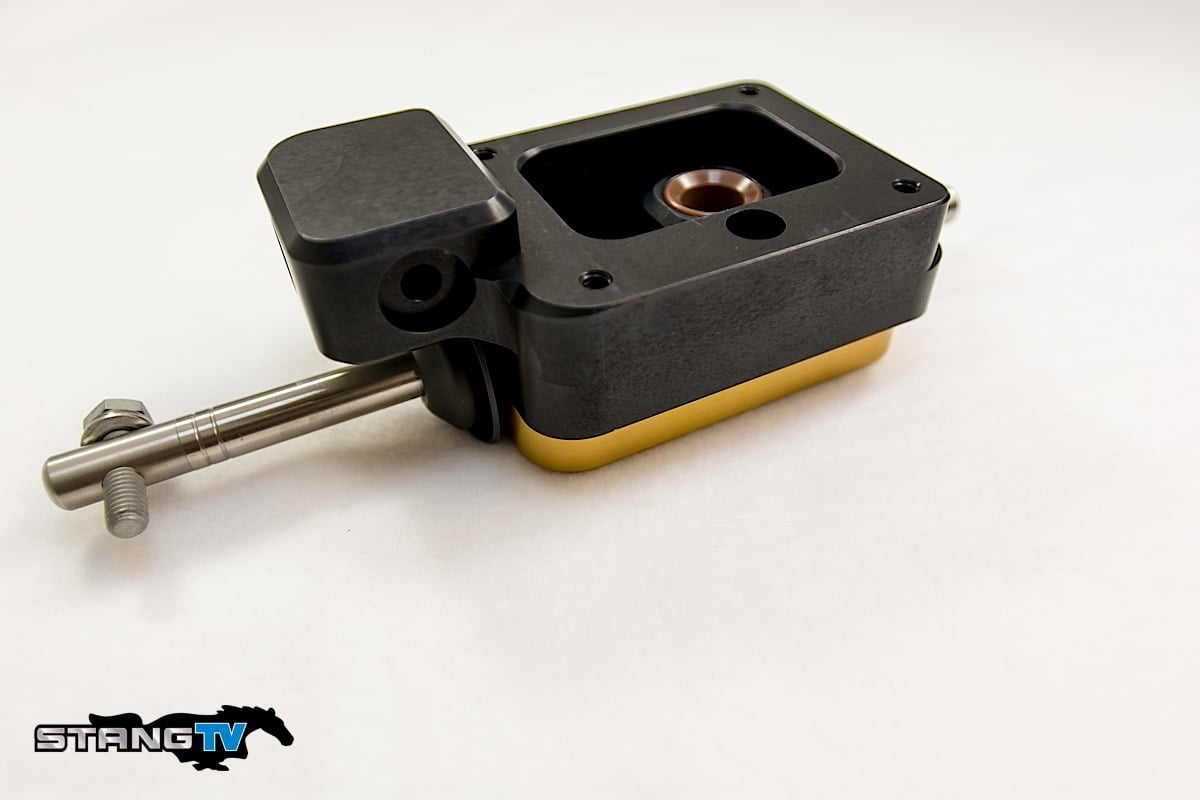

Precision CNC machined from 6061 aluminum and 303 stainless steel, the MGW Race Spec shifter is not only robust, but it is designed to give drivers the feel of a transmission-mounted shifter.

Our shifter doesn’t strengthen the transmission, it helps reduce the possibility of a missed shift, and that should help owners get better service life out of their transmissions. -George Ciamillo, MGW Shifters

We’re not the only enthusiasts to have such a sordid tale of shifting woes with our OEM MT82 remote shifter. Jason Reiss, our pal over at Engine Labs, and owner of Project Grabbr, our 2011 Mustang GT project car, has similar complaints with his car. We have read numerous accounts online, and heard it first-hand from other enthusiasts with the same issue. MGW’s George Ciamillo tells us he hears similar complaints regarding stock shifters on a regular basis. “Missing a shift isn’t good for the transmission, and aside from overpowering the transmission is a key reason why any manual transmission would experience shorter service life. Our shifter doesn’t strengthen the transmission, it helps reduce the possibility of a missed shift, and that should help owners get better service life out of their transmissions,” Ciamillo says.

The upper console shell must be removed to remove the OEM shifter. The shift knob is the first part that should be removed. Left: This panel, located on the bottom front of each side of the console, can be removed by hand. Work your fingers underneath it from the bottom, which is secured by a magnet and then slowly slide your hand around and gently allow each retaining clip to break free. Do not pry or apply excessive pressure, just sliding your fingers and hand around is adequate. Right: These two 7mm headed bolts are the only ones that will need to be removed from the console.

The MGW Solution

MGW is a precision machining outfit, and while we recognize it for the impeccable manual transmission hardware it produces, the company’s roots are in gun parts manufacturing. With a background in precision machining, where measurements of a thousandth or even hundred-thousandths of an inch are critical, MGW brings this same precision to its automotive products.

Left: Open the console glove box and insert a plastic non-marring trim tool into each side between the console shell and the glove box liner. User your fingers to gently lift up on each side to release the clips, and then reposition the trim tools to prevent the clips from going back into their slots. Now carefully slide your fingers along the seam of the upper console shell and release the remaining clips. Slide the upper console shell up and leave the shift boot in it, guiding the boot off the shifter. Right: With the upper console shell removed, you can now focus on the shifter. If you are removing the driveshaft you can skip ahead, otherwise we suggest following MGW's steps here as outlined in the video to disassemble the shifter assembly from inside the car. The plastic reverse lockout actuator is removed by prying up on the tab. MGW includes a roll punch to drive a pin out of the center of the shifter which must be removed in order to remove the lever from the car. EcoBoost cars will have much more room to work with than GT cars

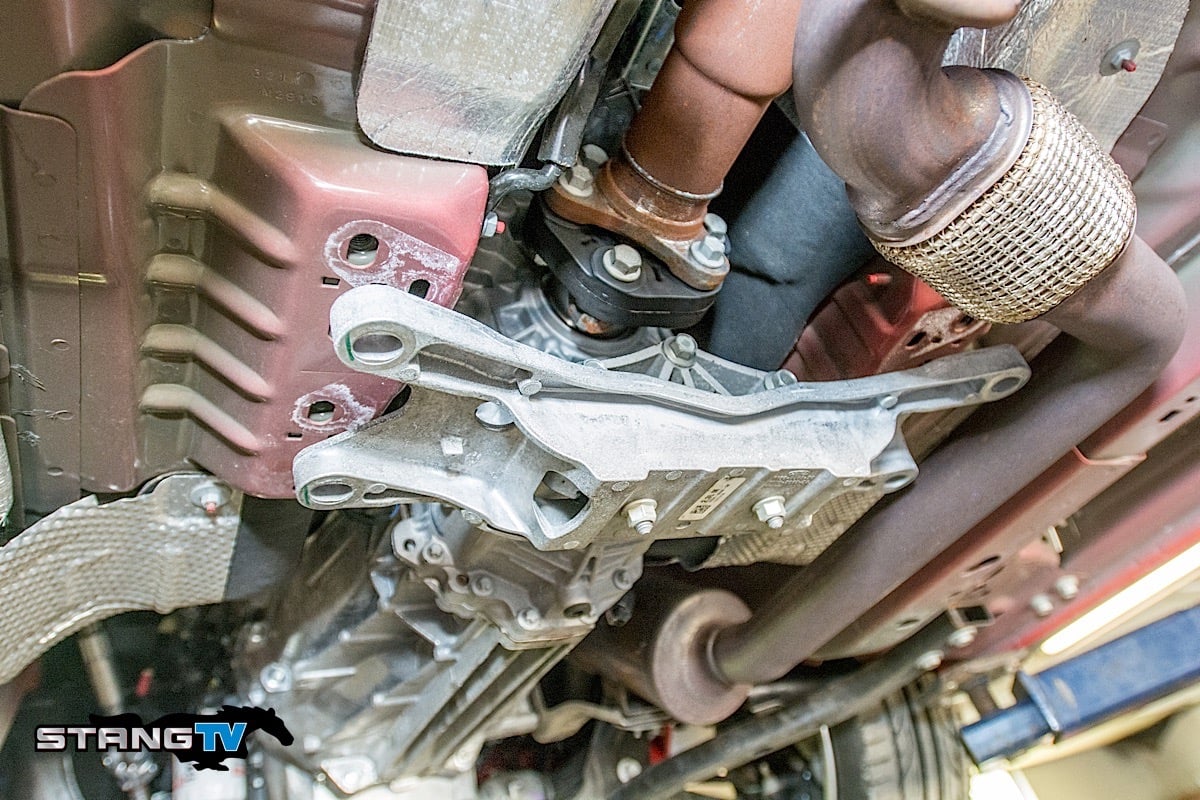

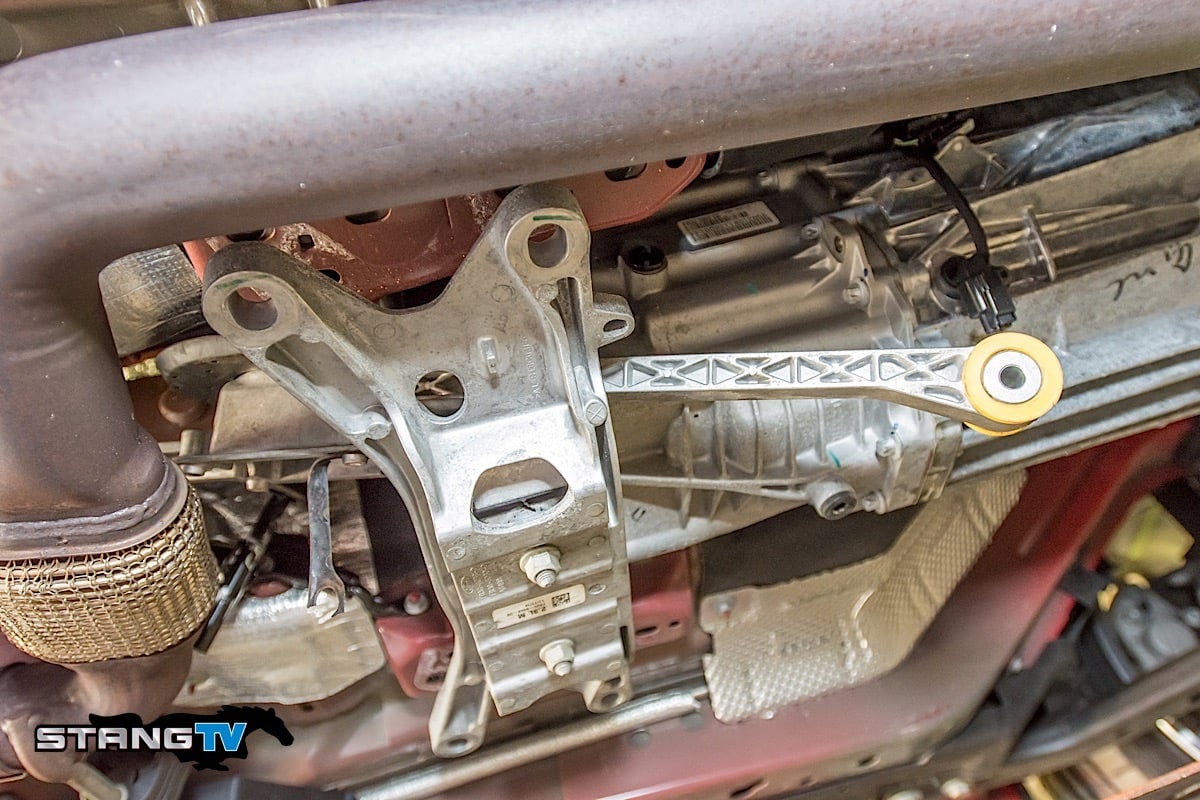

Left: At the very least the four bolts that hold the transmission cross member will need to be removed. If you can remove the driveshaft, it will allow the transmission to drop further, affording you even more room to work. Center: There are two bolts that hold this bracket which is the first piece under the car to be removed. Right: Once the bolts are removed the bracket comes out easily. Not pictured here, you'll need to access the shift rail pin bolt, and the shift support arm bolt, both are on top of the transmission, you'll need to feel around to find them. MGW shows this well in its video where the transmission is on a work bench.

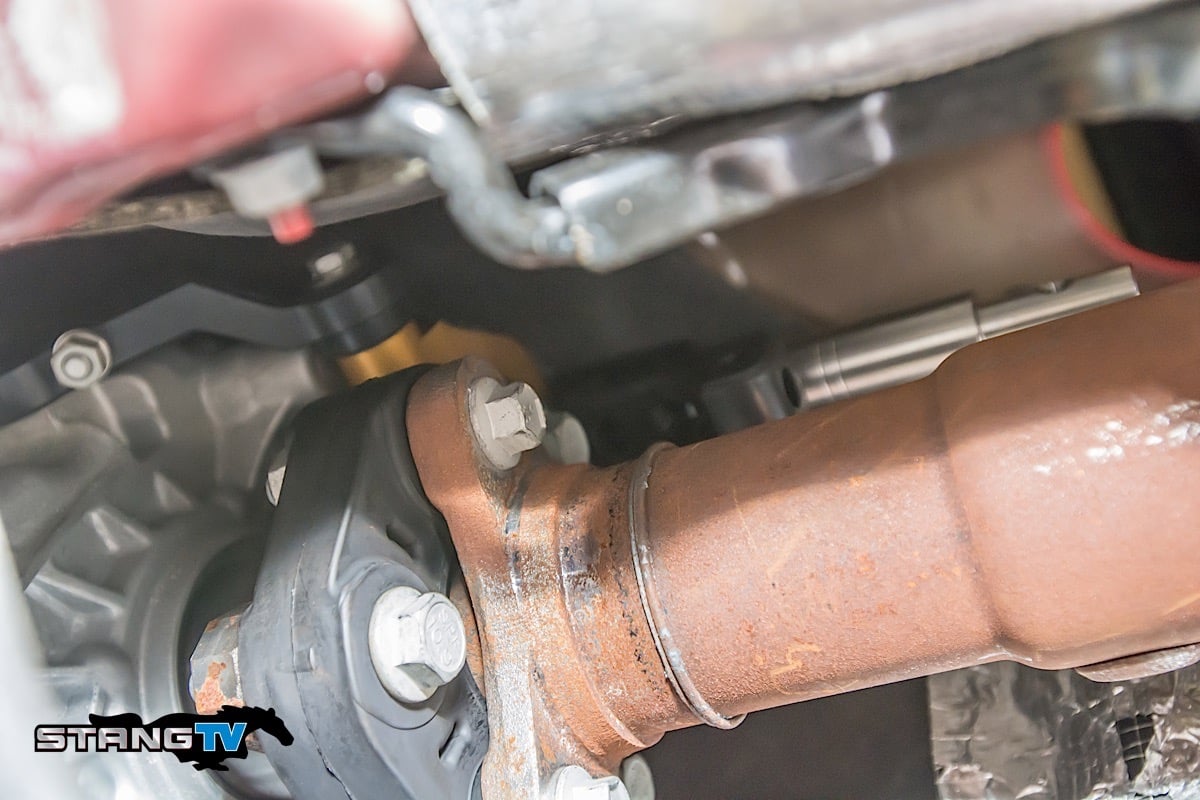

These are two of the four bolts that hold together the shifter assembly. The shifter should be easy to move around at this point allowing easy access with a ratchet and extensions.

The MGW Race Spec shifter is the latest evolution of its remote shifter design for Mustangs equipped with the MT-82 transmission. “We know a lot of our customers wanted the classic feel of a top-loader shifter like you’d get from a 3550 or 3650 Tremec in an older Mustang. So we came up with a way to do that, without the need to perform an expensive and extensive transmission swap,” Ciamillo says.

Ciamillo says MGW purchased a MT-82 transmission as an aid in designing the Race Spec shifter, so that all fastening points, and possibilities, could be taken into consideration when designing the shifter.

The Race Spec shifter is constructed from high grade 6061 aircraft aluminum and 303 stainless steel. All of the parts are polished, anodized, or even black nitrided – a process which improves harness and smoothness and is commonly used on firearms parts. The Race Spec design gives MGW a single shifter design that fits all 2011-2015 Mustangs equipped with the MT-82 transmission.

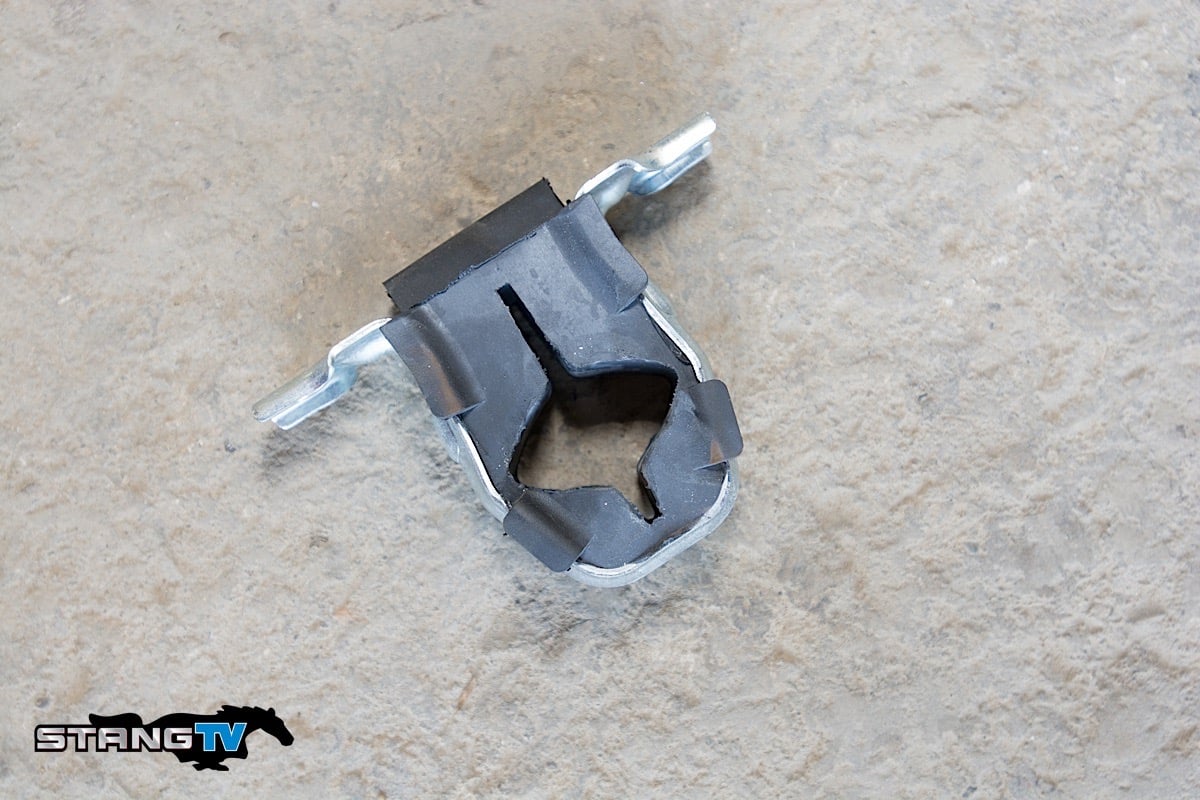

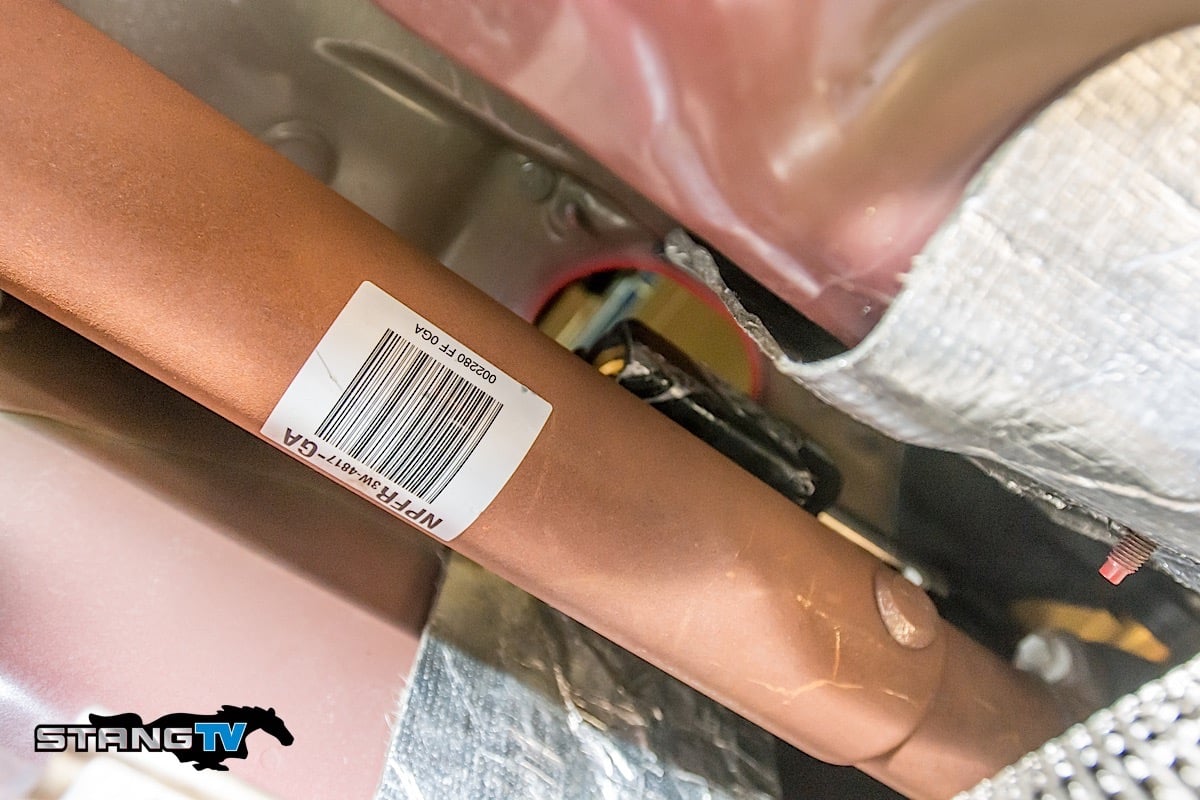

Top Row: Left and Center: With all of the bolts removed, the OEM shifter can be removed from the car with a bit of finesse. Right: The multiple pieces of stamped and cast aluminum comprise the OEM shifter. Bottom Row: This polyurethane cup and the foam bushing from the OEM shift actuator/arm must be removed and transferred to the black-nitrided shift linkage arm. The cup is keyed but can carefully be removed from the cup with a flat-blade screw drivier. The MGW part is keyed exactly as the OEM part. This rail is the first MGW part to be installed and does so using the OEM retaining bolt. Be sure to use some thread-locking compound on the bolt.

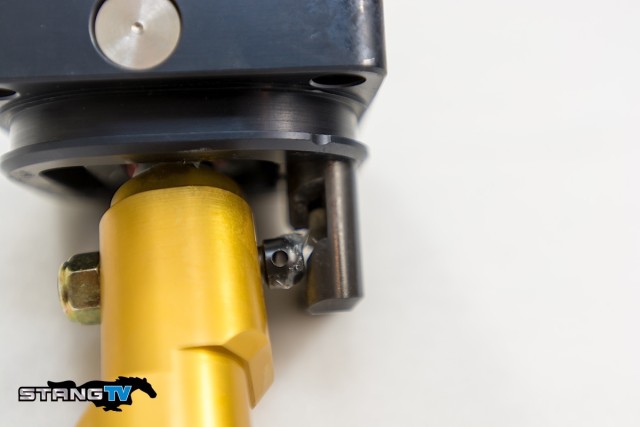

Aside from its robust construction, the Race Spec shifter uses a bridge assembly to give the shifter more of that top-loader feel. The linkage arm is black-nitrided for smooth operation and strength. The inner workings of the shifter, constructed from 303 stainless steel is precisely machined. When compared to the workings of the cast aluminum and stamped stock parts, the Race Spec is more than impressive in appearance and it should be up to the task of whatever hard shifting we can throw at it.

NVH

The MGW shifter bridge assembly improves shifter feel, and includes provisions to reduce NVH (noise vibration and harshness). Additionally MGW includes a piece of sound-deadening material, which should be cut into sections and added to the shifter during installation.

Lockout Change

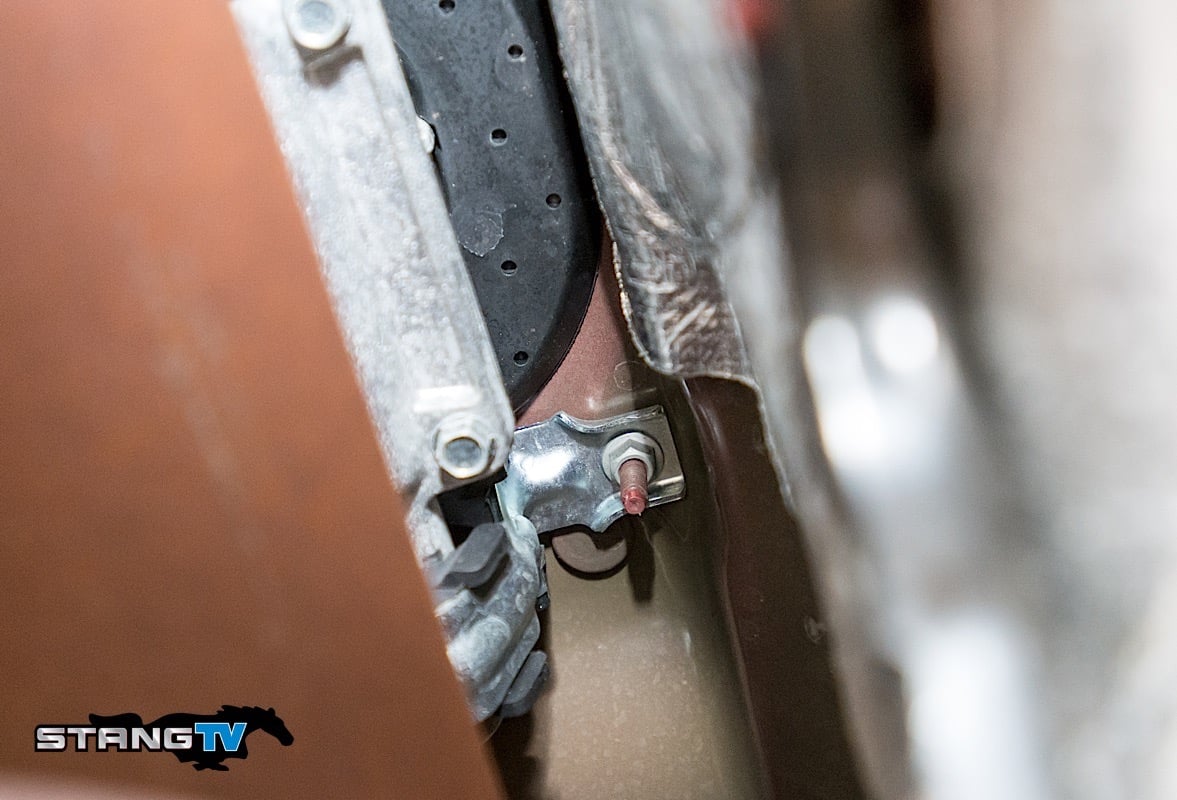

The stock shifter utilizes a lift up collar to allow the shifter to move into the reverse position. MGW uses a lockout plate and a push down design. The shifter is pressed down and moved into the reverse position to engage reverse gear. The plate not only acts as a reverse lockout but as a positive stop ensuring that second gear is hit every time since the shifter can be pulled in towards the driver and thus against the billet machined plate. Adjustments can be made by manipulating the installed bolt, allowing fine tuning of the shifter position for 1-2 shifting. Ciamillo says that 85-90-percent of MGW customers won’t need to make any adjustment from how the shifter came out of the box.

Noise Vibration and Harshness (NVH) is a key consideration for MGW. The Race Spec shifter is designed to reduce as much unwanted NVH as possible in a shifter of this design. Ciamillo says that MGW actually integrates metal-encased rubber dampers into parts of the shifter to help reduce NVH. A piece of sound deadening material is also included, to be installed on the shifter to reduce the amount of NVH transferred through the rigidly mounted piece of hardware. Heat insulation is included to further reduce heat transferred through the shifter from under the car. It’s a well thought out design. “We set out to design the shifter to be as good as it can be -it’s a compromise between the rigidity of a race environment part, while offering daily driver smoothness,” Ciamillo says.

Left: The OEM shift boot can be removed from the upper console shell by squeezing the retaining clips and pushing the boot assembly out. Turn the boot inside out and then use a hack saw, band saw, or other cutting tool to saw off the OEM plastic reverse grip near to where it meets the boot. Right: Turn the boot right side out and you will have a perfectly modified boot that retains OEM appearance and is compatible with the MGW shifter.

Install and Test Drive

We have outlined the installation highlights in our photos and captions here. In lieu of sending a printed instruction manual or disc, MGW produced a video that demonstrates every step of installation, including some bench-mounted coverage which makes finding a few of the harder to see bolts even easier. The video is a one hour long tutorial that we watched twice prior to attempting our install. We also had it on our smartphone so we could play it step by step as we conducted our installation. We previously covered this video in short, and you can find it here. We can not stress enough the importance of watching the video and using it in tandem with this article as reference for the installation. The two should provide more than adequate guidance to install the shifter.

Top Row: Left: The bridge assembly is the next piece to be installed. Make sure to put thread-locking compound - which is included, on all the bolts prior to installing this part in the car. The side supports simply slide over the caps on the side of the transmission. Leave the nuts and bolts that tighten these parts extremely loose until both sides are on and completely flush against the transmission. Center: Next to go in is the shifter box. This requires finessing it into place and slid into the shift arm and the bridge assembly. The bolts on this will also need threadlock compound. Right: At this point the transmission cross-member can be bolted back into position and the car lowered to complete work inside the car. The reverse lockout spring and its end caps need to be installed, but should be lubricated with the supplied grease first. The inside of the shifter box and the cup should also be thoroughly lubricated with the supplied grease. Bottom Row: Left: Carefully align the shift lever assembly with the cup and the spring and then lower it into place. Then secure it using the supplied Allen head bolts and tool provided by MGW. Center: The MGW supplied inner shift boot goes on next. At this point make sure that the shifter engages all gears properly, paying special attention to reverse, 1, and 2. A quick tip to installing the inner shift boot easily is to thoroughly lubricate the lower grooved section with dish soap, then slide it over the shifter. The lower groove should fit the floor pan. The supplied zip tie then goes around the shift lever to secure the boot at the top, just like the OEM part. Right: Install the MGW sound-deadening pad, followed by the OEM pad, and then reinstall the console shell and shifter boot.

After borrowing a lift from friend Ronnie Barrickman of Barrickman’s Towing, Editor Don Creason was able to install this shifter easily, although this was the first remote shifter he had ever attempted. The MGW video is thorough and the parts are so well made that any nuts and bolts-enthusiast should be able to tackle this install in under two hours. If you are replacing the exhaust mid-pipe, or driveshaft, install this shifter during that operation doing so will make the the shifter install even easier. If desired, the driveshaft and exhaust can be dropped to allow more access to the top of the transmission, further easing installation.

Install the jam nut on the shift lever and turn it all the way down. Then, install the shift ball until it comes in contact with the jam nut or bottoms out. Do not over-tighten the shift ball or it may break. From here, loosen the shift ball off at least one full turn, plus whatever is needed to center the shift pattern. Then, use the included wrench to tighten the jam nut against the shift ball. You may have to adjust this after the first time you drive the car. The most important thing to remember is to not crank down on the shift ball.

We have yet to head back to the autocross or the drag strip with our new MGW Race Spec shifter on board. However, driving on the street, this shifter has left more than a good impression. There is zero difference in the amount of in cabin (or out) noise level. Although a small amount of additional vibration from the engine and transmission are transmitted back through the shifter due to its rigid design. It’s worth noting that since the shifter itself is not body mounted that vibration never makes its way to other parts of the car like the chassis or floorpans, and so its energy is never changed into noise -it’s only noticed when a hand is placed on the shifter, and not nearly as severe as an older Mustang equipped with a T5 and an aftermarket, or even a stock shifter.

We set out to design the shifter to be as good as it can be -it’s a compromise between the rigidity of a race environment part, while offering daily driver smoothness. -George Ciamillo

We’ll be interested to see how our MT-82 endures as we continue to increase power. With our MGW Race Spec shifter installed, we’re now more confident than ever that we can row gears without worry in any driving situation. While our stock shifter was fine for daily driver duties, after just a few miles of driving we were left wondering how we ever got along without the Race Spec installed.