Seeing a project transform from a dirty old rust bucket into something that actually drives well and keeps up with the modern pace on the road is something truly magical. While the components to accomplish this goal are fairly simple, aligning them with the end goal of your project in mind is a different story. No matter what you plan to do however, you need the “gears” to turn, so-to-speak. That’s what we are going to focus on in this story.

Seeing a project transform from a dirty old rust bucket into something that actually drives well and keeps up with the modern pace on the road is something truly magical. While the components to accomplish this goal are fairly simple, aligning them with the end goal of your project in mind is a different story. No matter what you plan to do however, you need the “gears” to turn, so-to-speak. That’s what we are going to focus on in this story.

In honor of the poor execution of Chrysler’s debut of the new 2013 Dodge Dart, we at Street Legal TV would like to keep the wheels turning on our 1971 Dodge Dart Swinger project car, otherwise known as Project Bull-Z-Eye. This particular Dart came stock with a puny 7.25-inch rearend from Chrysler. Mated with a 904 transmission and the stock 318, this was adequate for 1971 and the demographic buying the car (yes, we all know your grandmother probably drove one).

These Strange bolt-in S60 rearend differential assemblies are designed to fit your vehicle without any modifications.

But we of course don’t do “adequate” and we certainly are not happy with the grandma status. With a daily driver and street/strip application in mind, we looked no further than to Strange Engineering and their S60 rearend assembly.

The premium nodular iron casting features threaded adjuster nuts for easy gear installation and bearing preload. The S60 also provides superior rigidity for longer gear and bearing life and accepts Dana 60 internals.

The S60 was developed by Strange Engineering to exceed the demands of hardcore drag racing and street performance, and this works perfectly for our plans for a new motor (shhh… it’s a secret!).

Strange S60 Features

- All new Strange designed S60-cast from premium nodular iron

- Adjuster nuts for precise and easy set-up

- Large nodular iron caps

- One piece center casting for enhanced rigidity

- “Bolt-In” for Chrysler A, B and E-body cars-fully machined to accept factory and most aftermarket pinion snubbers

- Strong 9.75 OD ring gear diameter

- Strange S-Trac limited slip differential

- 35 Spline S Series alloy axle

- Fully welded (360 degree) tubes

- Includes Lucas Oil 85w-150 gear oil

- No friction modifiers needed

Years ago, the 12-bolt rearend was an excellent choice for street/strip enthusiasts…no longer. The ever increasing availability of additional horsepower and torque has rendered conventional rearends inadequate.

The idea behind using this rearend in our Dart was to make it bulletproof. The Strange S60 adopts a very close design to the Dana 60 and will accept Dana 60 internals. The 9.75-inch ring gear can endure a tremendous amount of abuse, equal to a Ford 9-inch rearend.

Depending on your particular application strange engineering offers a few differential options. For a typical streetcar and daily driver, the Strange Trac-Lock would be an ideal unit, however, this project requires something that will handle a bit more horsepower.

Our S60 is equipped with the Strange S-Trac which is the perfect multi-purpose unit good for street, road racing, and drag racing.

The Dana 60 35-spline Strange S-Trac installed in our S60 rearend accepts ratios: 3.54, 3.73, 4.10 and 4.30 US Gears. The internal gears are designed from 9310 steel and are helical cut which provides optimal strength, smooth power flow, and traction.

The helical gears operate like an open differential under normal driving conditions, but as soon as you need traction, the gears wedge themselves together and act as a posi.

One of the advantages that comes with the S-Trac, and due to it being a torsion style differential, makes it non-wearing. This means it can take just about anything you can throw at it. It also means you will almost never need to rebuild the rearend, granted of course that you take good care of it.

The S60 is slightly heavier, coming in at 15 lbs. more than a comparable 9-inch rearend, and 20-25 lbs. more than an aftermarket 12-bolt. The S60 rearend is equipped with 35-spline S series alloy axle shafts and we upgraded our bolt pattern to a 5×4.5-inch for our new American Racing wheels.

The S60 is available as a bare rearend ready for fabrication or as a completely welded bolt-in rearend. We of course, ordered ours completely ready to bolt-in. Additionally, the Strange S60 rearend features 360 degree fully welded tubes, large 3.150-inch ID housing ends and a 1350-series yoke for additional strength.

Every rearend is purpose built from scratch to the customer’s specifications. The castings are put into a fixture where the tubes, brackets, and ends are installed to assure housing straightness and proper bracket location.

The housings are then cleaned and moved to the assembly area where highly trained technicians install the gears, differentials, axles, and related parts. Every assembly bears the name of the set-up technician scribed into the O.D. of the ring gear.

Strange Engineering assembles the S60 and all of their rearend offerings on jigs, set up by experienced technicians. They use state of the art, million dollar plus equipment known as Mazak machinery to ensure that each manufactured product meets specifications. This is the same department that assembles rearends for top fuel dragsters and funny cars.

The technicians at Strange Engineering take extreme precaution during the final prep of the center section prior to sealing the rearend.

Each bearing, seal, and component is measured in to place and triple-checked before moving on to the next step. Each rearend is fully crated to ensure the recipient of an uneventful delivery experience.

The S60 offers a strong, reliable, affordable option that can bolt-in to the vehicle and give the owner the peace of mind in knowing that portion of the car is done.

– J.C. Cascio

It’s beefy center section and housing still fits snug, however, we did need to make some small adjustments and push the fuel tank less than an inch back to provide enough clearance when the suspension is compressed.

It’s also worth mentioning that the S60 ships with bare metal axle tubes. We applied some automotive grade black paint to not only match the S60 rearend housing, but to prevent any rust in the future as well. The rearend is shipped raw so it can be painted any color by the owner.

Installtion of the Strange S60 is straightforward. All of the parts are included and it simply bolts right in.

Installing a rearend that comes completely ready to bolt-in makes life much easier, so we did just that… bolted it in. The original leaf springs, mounts, and bolts can all be re-used, however, we opted to upgrade a few of these components considering they are over 40 years old; it is always a good idea to replace old hardware when you can.

The Strange S-Trac differential provides a smooth and reliable posi that utilizes helical gears to distribute power to tires. The S-Trac differential has been thoroughly field tested and proven.

Additionally, the stock driveshaft is often another component to upgrade or replace, but for now, we decided to simply rebuild it. Both ends of the driveshaft were fitted with a new yoke and new 1350 u-joints. This will be enough to get us by until we’re ready to do something with the powertrain.

The new leaf springs, Viking shocks, and Wilwood brakes make for one mean handling ride when mated to the Strange S60.

We found out in a previous article that the stock bolt pattern that shipped with the majority of the 7.25-inch rearend equipped Dart’s included a tiny 5 on 4-inch bolt pattern. Finding wheels to fit this bolt pattern is next to impossible; at least finding a decent looking wheel. So, as many people know, upgrading one component in a project often requires upgrading an associated part, or parts in our case.

With the new bolt pattern comes the need for a new braking system. Wilwood Brakes supplied a set of Forged Dynalite Big Brakes for the front and rear. The 12.19 inch rotor and 4 piston calipers provide the stopping power needed for future upgrades. The red calipers also add a great look to the wheel/tire combo.

We thought the bright red calipers, new leaf springs, and rearend really take this project to the next level.

The suspension on this ’71 Dart really hadn’t been touched and remained fairly stock for many years. With the new components in place, drivability is going to increase from the stock, floating feeling that most classic cars have after 40 years of driving and sitting.

Complementing the Hotchkis leaf springs and stock torsion bar suspension in the front, Viking Shocks sent us their VSK217 shock kit which includes four double adjustable shock absorbers.

This adjustability gives us a huge range allowing us to configure just the right settings for comfortable cruising to high performance driving, and even a setting for in-between driving styles.

Each valve adjustment is evenly spaced and offers 19 positions of compression adjustment and 19 positions of rebound adjustment for a total of 361 different valving combinations.

Once installed, we chose to set the shocks to a comfortable setting somewhere in between a performance driving and comfort driving compression rate, somewhere between 6-9 clicks for compression and rebound. This gives the car a more firm ride but will remain comfortable enough to drive on a regular basis.

New leaf springs make all the difference in the world; especially when you are replacing 40 year old stockers.

The Hotchkis Geometry Corrected Leaf Springs improve this classic A-Body’s cornering performance and traction, along with dropping the rear of the car 1-inch, which will improve the cars stance.

Every shock is dyno tested, serialized, and hand built in the U.S.A. at Vikings Lakeville, MN facility. They feature a lightweight aluminum body with a clear anodized finish, precision machined pistons with PTFE | bronze piston wrap and 5/8

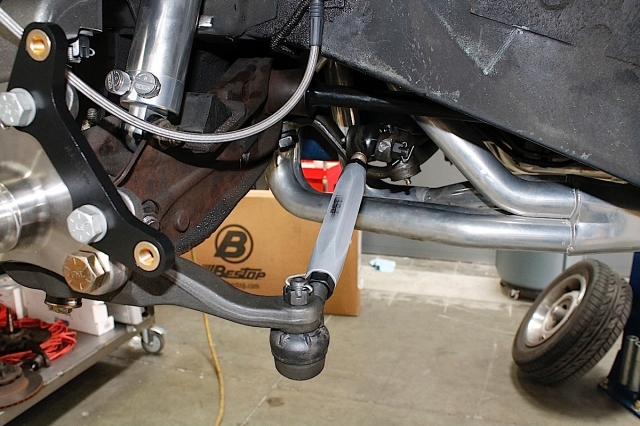

With the new Strange S60 rearend, suspension, and brakes installed, it was time to move to the front of the car. When the Dart was purchased, some very light modifications were made to the front suspension, but all of the components were relatively stock.

The previous owner added a front sway bar, new lower control arms which are a boxed metal design, and replaced most of the steering linkages. All Darts featured a front torsion bar suspension, which has its pros and cons. However, in this case it works in our favor giving us some adjustability in ride height. This will come in handy when the car is back on the ground and we can match the rear ride height which is now 1-inch lower than stock.

This is what 40 years of beating pavement will get you. These brakes were considered an upgrade back then... now? Not so much.

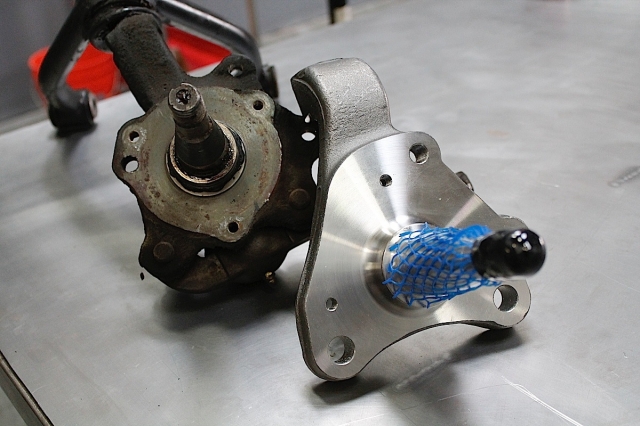

Out with the old and in with the new. Upgrading the front suspension and brakes requires a ’73-’74 A-body knuckle.

With the new brake setup from Wilwood, the most important component to replace are the front steering knuckles. This is a common upgrade for installing a larger brake kit, and many Dart owners opt to go with a 1973-’76 Dart setup, which came standard with front disc brakes.

The new knuckles mount perfectly into the stock location and will help us to upgrade the bolt pattern to a 5x4.5 inch.

Our Dart included the Kelsey Hayes disc brake upgrade from the factory back in 1971. This was probably the most common option chosen for the Swinger back then and is an extremely common setup to swap out to a larger, more common bolt pattern. So naturally, the new Wilwood brakes feature the same 5×4.5 bolt pattern as in the rear for our American Racing wheels.

PST Performance tie-rod ends and adjustable sleeves for ultimate adjustability and endurance.

There are some additional issues that we tackled before we were able to get too far into the front suspension setup. The new knuckles require some stock components to be replaced with better, more compatible parts, mirroring the 1973 setup.

This is PST’s Steering Linkage Kit to go along with our PST Tubular Front Control Arms and can also be used with PST’s Ball Joint and Shaft Kit.

To go along with our new front knuckles, PST Performance Suspension provided a set of new inner and outer tie rod ends and solid steel adjustable tie rod sleeves. Each of these components are essential for critical alignment and any wear significantly adds to steering looseness or “play.” The new tie rods have been upgraded to 11/16-inch for strength and are a common Mopar upgrade. The larger sleeves and ends normally found on the larger C body cars are simply stronger, and are a direct-fit replacement.

The new tie-rod ends will beef up our front suspension dramatically. The solid adjusters instill confidence over the factory split-tube design.

Also, with the new knuckles, we upgraded to a larger upper and lower ball joint, so once again, PST took care of us by supplying a new upper control arm and lower ball joints.

The tubular control arms provided by PST, also known as the G-MAX Tubular Upper Control Arms, resolve suspension geometry issues by adding better camber/castor adjustability. By resolving two issues at once, we get better suspension geometry and the larger ball joint to accommodate the new knuckles.

Fabricated from heavy duty MIG-welded DOM tubing, these lightweight arms come pre-assembled with Polygraphite bushings, bump stops and new ball joints.

The final steps to complete this very involved update of our 1971 Dodge Dart Swinger is the best part of the project. Dropping it down and observing the new stance and look of all these high quality components we installed.

Conclusion

Strange recommends driving lightly on the new S60 rearend for the first 500 miles. Once you hit 500 miles, they recommend replacing the gear oil, which they have graciously provided in the kit.

The S60 ships with Lucas Oil SAE Heavy Duty 85W-140 gear oil and recommends always replacing the gear oil with the same. This ensures proper break-in of the gear components and adequately lubricates the gears and axles, removing any manufacturing dust and metal fragments or initial wear from first use.

Upon light acceleration, it was easy to tell the new gear ratio already added some get-up-and-go to the car. The clunky and loud sound of worn out bearings from a 40 year old rearend was finally behind us and replaced with a smooth rolling, silent Strange S60 rearend.

Gear Oil is an important factor and changing gear oil within the first 500 miles of using a new rearend will make sure the S60 lasts forever without any foreign artifacts.

The suspension did it’s job very well too. Once the car was settled into it’s new stance, the increased handling and stiffer, more modern ride was greatly noticed. The best part about the ride quality, is that at a moments notice, we can simply adjust the Viking shocks to a more track ready setting, or if we decide to cruise down to the beach, adjusting the shocks to a more comfortable setting is all possible.

We accomplished a lot with our 1971 Dart Swinger and added a lot of great performance parts to get us closer to our goal with Project Bull-Z-Eye. We have the suspension to handle the track or the street, we have the stopping power to accommodate a larger motor in the near future, and we have a bulletproof Dana 60-esque rearend, known as the S60 from Strange.

The S60 is a dramatic improvement and sets the stage for some big power. This install proves Strange knows what they are doing when it comes to building a quality rearend. The future is looking bright for our Dart and we are ready to take on some series projects from here on out.

The 1971 Dodge Dart project car, also known as Project Bull-Z-Eye.