Cylinder head port designing is an incredibly complex process, which is why most shops leave it to the cylinder head manufacturers. Then, you have shops like Prestige Motorsports, which have their hands in all aspects of engine design. Instead of buying off-the-shelf ready-to-run cylinder heads for their projects, they opt to invest the time and resources into developing their own programs. Not just designing port shapes, either. Prestige custom designs the valves specifically for each application.

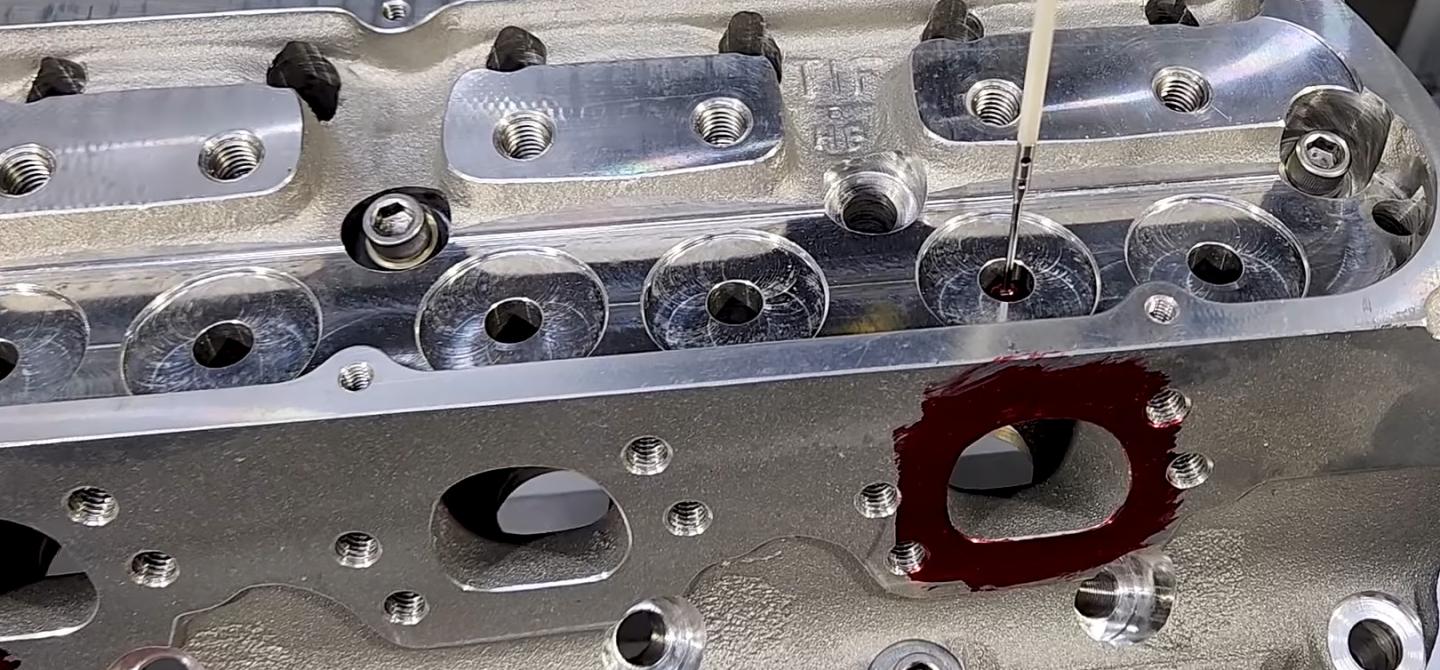

Starting with a bare, unported Brodix 15-degree Head Hunter small-block Ford cylinder head the team at Prestige is painstakingly developing their own CNC programs for every aspect of the casting, so it is sure to perform exactly as they want. In this video, Prestige’s CNC Manager, Cory Messerli, goes over the development of the valve-related parts of the cylinder head project.

“The first step is to establish our valve spacing. That’s the most critical part at this stage,” explains Messerli. “We’ll put it in the Centroid and establish the intake and exhaust valve locations.” With that data, Messerli can get to work building his virtual workspace in the CAD software. From there, he knows how much room he has to work with, and starts developing potential intake and exhaust valve size combinations. “We don’t want to see too tight of a distance between [the intake and exhaust valves] because, when the engine is running, you can run into a situation where they start clipping each other, and that’s a no-go,” says Messerli.

With only a preset amount of room to work with, potential valve size combinations are run through, balancing intake and exhaust flow with physical spacing concerns.

Building To The Available Space

As he runs through potential valve sizes, he shows the clearance between the valves for each combination. “With a 2.180-inch intake valve and 1.625-inch exhaust valve, you only have .030-inch of clearance. That’s a little bit too tight for what we like. Then you go to a 2.180-inch intake with a 1.570-inch exhaust valve, and we have almost .060-inch of clearance. And that is too big.”

As we’ve learned over the past decades, it’s not always about just shoving the biggest valves you can fit into a cylinder head. It’s about finding the sweet spot. So what Messerli is doing, is finding his upper and lower limits, so he knows what he has to work with. “We try to work within these windows, and I try and come up with a good combination of what will offer the best performance for an N/A application, a turbo application, and so on,” Messerli explains.

“You also have to take into consideration the intake seat ring and the exhaust seat ring sizing. In this particular case, we have a 2.250-inch intake valve seat, and a 1.650-inch exhaust valve seat. We try not to have our valve sizes more than .040 inch within that max diameter. With the 2.250-inch intake, our maximum valve diameter is 2.210 inches. With the 1.650-inch exhaust, our maximum exhaust valve size is 1.610 inches.”

Picking valve sizes might not seem like the most important starting point of the cylinder head design, but from Prestige’s perspective, it really is. “The biggest hurdle we have right now is getting valves. The lead time on valves is anywhere from 10 to 16 weeks, so we want to make sure we have the right valves before we place an order.” Messerli reveals.

In order to quickly test new valve designs on the flow bench, Prestige uses a threaded valve stem and then machines “pucks” — or temporary valve heads — out of aluminum. They are much cheaper and faster than cutting entirely new valves for every idea they want to test. Once satisfied with the design, they will order the custom valve design in bulk.

After The Valves Have Been Sized

With the valve sizes chosen, the next step in Messerli’s journey is determining valve geometry. Different from the valve angles, this process involves the actual shapes of the valves. “What kind of underhead shape are we going to use? What are our margins going to be? There are a lot of variables that we have to test on the flow bench to figure out what we really want,” says Messerli.

The method used by Prestige to test all of this is really interesting, as they turn down and thread a valve stem, and then spin on different valve heads, or “pucks” as Messerli calls them. “We make various aluminum pucks that screw onto the valve, so I can go back and forth on the flow bench and test all the different possible combinations. Say a 10-degree underhead against a 20-degree underhead, or a 12-degree underhead. Really it’s almost endless what we want to test.”

This ingenious system allows for rapid prototyping of new valve designs from an easy-to-machine and inexpensive material, which, on the flow bench, performs the same way an actual valve will. And to do it all before placing an order for 100 sets of custom-made valves. This is a cool look into the process of developing a cylinder head design, and we’re already excited for the next installment in the series.

Here are two different “puck” designs laid over one another. The rear design is a 2.180-inch intake valve with a 10-degree underhead angle. In front is a 2.200-inch intake valve, with a 20-degree underhead angle and different valve seat angles and margin thickness. Being able to rapidly test these differences prevents any ordering mistakes and shortens R&D times.