Reliable 87-octane, big horsepower has been the Holy Grail for both enthusiasts and engine builders for some time now, with many choosing forced-induction to achieve that goal.

However, boost is not necessary to achieve dyno-twisting numbers. As the old saying goes, there is no replacement for displacement, and with that advice it’s a good idea to start with a base that will accomplish the goal while keeping the stress load on the parts in a manageable zone. The big-block Chevrolet is an excellent starting point, with a design proven over the the last 40 years by numerous engine builders in a variety of street cars, hot rods and race cars.

The finished engine boasts a colorful and well-detailed appearance as it will be showcased in a boat.

The BBC engine has undergone a number of revisions since its inception, but the Mark IV design — first introduced in the 1963 Daytona 500 stock cars — has become the staple in the industry for big performance out of a workable package. Aftermarket improvements such as cylinder heads, camshaft and valvetrain design have only added to its success. Recent developments in these areas, thanks to computerized flow modeling, have added to the mystique of the “Rat” motor.

The customer wanted to retain the ability to chug around on the water using nothing more than 87 octane fuel. – Mike Petralia, Hardcore Horsepower

Pistons were set up .010-inch in the hole to keep the compression ratio at a pump-gas-friendly 9.0:1. Domed piston volume can only be estimated by the manufacturer, so Petralia sets the piston up in the bore to find the true dome volume to assist in calculating actual compression ratio. At .300 below deck, the dome measures 22cc’s. Petralia then follows up with a computer-based formula to finish the calculation.

“This customer called me with the goal of having an engine that could achieve between 500 and 550 horsepower, but he was only looking to spend about $10,000. He was hopping up an old 1970’s ski boat with the hopes of selling it for a profit, and he wanted some bling added to his engine to catch attention at the lakes. So the final price for his marine-approved engine was closer to $12,000, but the same power could be built for a street car or truck for less than $10,000,” Petralia explains.

A strong base

Anyone could scour a local U-Pull-It yard for a big-block Chevy crankcase, as they were delivered in millions of vehicles prior to their demise in 2007, which by then were known as the 8.1L Vortec 8100. This customer wanted peace of mind, and to that end Hardcore took a different route by selecting a new, American-made Chevrolet Performance Parts 454 cast-iron engine block. This casting incorporates all of the best innovations through the big-block’s development. Revised oiling benefits larger cam bearings and increased camshaft lift, and the block has additional clearance for roller-style timing chains. Also, there’s additional material around the lifter bores to support larger-diameter lifters.

Measuring the bore after final machining operations is critical – it allows Hardcore to place each measured piston in the best cylinder to complement those dimensions. These measurements are taken in ten-thousandths of an inch.

It arrives with a fully-finished 4.250-inch bore and can be bored out to 4.310-inch maximum dimensions. It’s also clearanced for a bigger crankshaft stroke for increased displacement. The 4-bolt main caps are constructed from nodular iron and have 1/2-inch main bolts on all five mains, to go with a 1-piece rear main seal to help prevent leaks.

Petralia attached a torque plate to the top of the block and bored each of the eight holes to a 4.28-inch final dimension. He finished the block with a 9.800-inch deck height, which, when combined with the Eagle Specialty Products 4.0-inch stroke cast crankshaft and a set of SCAT 4340 forged-steel 6.385-inch I-Beam connecting rods, brings this internally-balanced big-block in right at 460 cubic inches.

Each piston is measured to provide Hardcore with its dimensions – Petralia has a detailed spreadsheet where each critical engine dimension is recorded for a true, fully-blueprinted engine. Fel-Pro gaskets are used to seal up the block-to-cylinder-head joint. In this application, a .039-inch thick, 10.5cc gasket is used to keep the compression ratio pump-gas-friendly.

SCAT’s rods are sized, balanced and weight-matched to plus/minus 1 gram. In this application the I-beam design was deemed worthy to support the horsepower while remaining light enough to rev up quickly without hindering performance. The big ends are secured with 7/16-inch ARP capscrews, and the little ends are fully bushed to provide smooth operation. The connecting rods have a single beam that runs across the rod cap to provide added strength and bearing support, while the beams have been polished to eliminate stress risers.

Filling the holes

Leak Detection

Tech Tip: Checking For Leaks

During the build process, Hardcore checks every single engine they complete for water and oil leaks. This leakdown tester is employed along with a number of custom-made plugs and caps to seal up the engine and ensure its integrity once the build is complete. Petralia has found this, in conjunction with an oiling-system check, to cost him only a few minutes of build time while potentially saving hours on the dyno.

Simplicity prevailed when selecting components for the oiling system. A Melling high-volume oil pump relies on a welded pickup to supply the oil from a Moroso street-strip wet-sump 6-quart pan. The pan features a 4.25-inch front depth and 7.75-inch rear depth to keep the oil under control on the street. An ARP oil pump stud is used to retain the pump in place, and a Melling heavy-duty pump driveshaft turns the gerotor-style pump.

A three-angle valve job was completed on the cylinder heads along with the port-work; for this power level, the American-made head castings don’t need much work at all. Petralia is meticulous about checking for leaks – the simple test of filling each port with solvent and walking away for an hour tells him how well the valves are sealing up.

In order to prevent leaks, Petralia relies on a one-piece silicone rubber pan gasket and locking fasteners – because who wants to deal with a leaky oil pan on a brand-new engine? Standard-sized King HP engine bearings keep the crankshaft’s mains fully lubricated, while their HP Series performance bearings are slid into place on all eight connecting rods.

Often stressed during the discussion of this engine’s design was the importance of the cylinder head design and maintaining the required powerband. Hardcore’s own American-made castings feature 320cc intake ports to go along with the 115cc combustion chambers.

“While some port work was performed, it wasn’t much; just a port-match with a bit of bowl work and work in the chambers was necessary to meet the performance goals of the customer using these castings,” says Petralia.

Air In, Air Out

Intake valve size was locked down at 2.250-inch, while the exhaust is pulled out through a set of 1.88-inch valves; all valves are stainless steel and have 11/32-inch stems surrounded by Viton valve seals. The heads were torqued down with a set of ARP six-point HP series head bolts, and .039-inch Fel-Pro gaskets were used to keep the combustion pressure in and the water out of the chambers.

In keeping with the engine’s goals, Hardcore chose a hydraulic flat-tappet camshaft from Comp Cams. It features 244 degrees of duration at .050-inch lift on the intake side, while the exhaust gases are treated to 254 degrees of rotation. Lift figures are also on the mild side for a big-block at .570-inch intake and .575-inch exhaust, the camshaft is installed on a 112-degree lobe separation angle, and is spun with a double-roller timing chain for timing accuracy.

Degreeing the camshaft is an important step in the build process. It ensures that the engine will operate as intended. Each cylinder head is inspected numerous times throughout the build – they need to be put together and taken apart to check the springs, valve seal, and perform the port work and valve-seat machining operations.

This camshaft provides the engine with a broad, non-peaky idle through 6000 rpm, which is exactly where a street engine sees most of its run time. Comp’s Pro Magnum .842-inch diameter lifters actuate the valves through a set of .080-inch wall, 4340 chromoly hardened Comp Cams High Tech pushrods. The pushrods measure 3/8-inch diameter on all sixteen; while the intake pushrods are 9.600-inch long, the exhaust pushrods check in at 8.600-inch dimensions.

The bumpstick required the use of dual valve springs with dampeners installed at 1.950-inch for 120 pounds of pressure on the seat with 350 pounds of open pressure to control the valvetrain at speed. Ten-degree hardened locks and retainers keep the valves in place, and Petralia used a set of 7/16-inch screw-in rocker studs with aluminum 1.7:1 ratio roller rocker arms to actuate the valves.

In The Cell

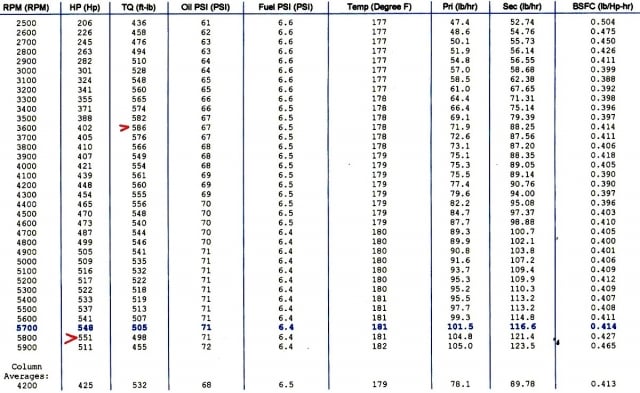

Instead of throwing the valve covers on and pouring the oil down into the valve cover fill hole, Petralia ensures that there’s plenty of dino-juice for the flat-tappet camshaft upon startup by dumping it into the drainback holes and directly onto the camshaft. Dyno time proved out the performance of this beastly pump-gas engine, as it spun the needle to exceed the goal numbers set out at the beginning of the build.

With the long-block complete, Hardcore turned its attention to finishing off the induction system. A simple combination like this requires the use of proven parts, and that’s exactly the direction Petralia headed during the initial design phase. Edelbrock supplied an Air Gap Performer RPM dual-plane manifold, which was topped by an HVH 1-inch Super Sucker spacer and Quick Fuel marine 4150HP mechanical-secondary carburetor. In a long-life budget application, Hardcore leans toward Autolite projected-tip iridium spark plugs.

The budget-minded big-block cranked out 551 horsepower on 87 octane fuel with peak torque coming in at 586 lb-ft.

Other parts used in the build to finish off the engine were a set of GM Performance Parts black “crinkle” baffled valve covers with matching Bow-Tie logo breathers, Fel-Pro CorkLam steel-core valve cover gaskets, and a sweet billet timing cover. A Powerbond harmonic damper and MSD Pro-Billet mechanical advance magnetic trigger distributor were also put into place before it was time to head off to the dyno cell for the grand finale.

Torquing the cylinder head is done in steps to ensure the fastener is stretched to provided the proper torque load on the gasket. An electronic wrench is used for accuracy.

And oh, what a finale it was! This engine, which was projected in the initial design phase to make between 500 and 550 horsepower and come in on a budget under $10 grand, achieved both goals with room to spare. Final dyno numbers came in at 551 horsepower at 5800 rpm and 586 lb-ft of torque at 3600 rpm – results that will plant you right back in the seat when the right foot comes callin’, and not suck your pocket completely dry at the pump, thanks to the measly 87 octane fuel requirement.

“We built it with the lower compression in order to tolerate the lower-octane fuel, and once we were done with the development work on the dyno, I realized just how happy the engine was,” Petralia explains. “Five hundred-fifty horsepower and 586 foot-pounds of torque, and all of it done before 6000 rpm. Not only does this work great in a boat application, as it will live a long life under those conditions, it would also work very well in a 4×4 for off-road use.”

Engine development goes hand-in-hand with hours spent testing and proving out theories, and it’s apparent that this engine lives up to its billing. Putting it all together requires proper planning and careful parts selection, and Hardcore Horsepower showed us that gobs of power are still well within the realm of possibility, at a price that won’t wreck a customer’s vacation plans.