According to the experts at Tri Star Engines and Transmissions, Checking your new engine’s exhaust back pressure is one of the most vital steps in avoiding not only restricted performance but also substantial damage. Internal engine damage such as burnt valves, blown head gaskets and other forms of premature, not to mention headache-provoking, engine failure can result when overlooking this step. When it comes to ensuring the health of your mill, it’s just not worth doing it half way.

According to the experts at Tri Star Engines and Transmissions, Checking your new engine’s exhaust back pressure is one of the most vital steps in avoiding not only restricted performance but also substantial damage. Internal engine damage such as burnt valves, blown head gaskets and other forms of premature, not to mention headache-provoking, engine failure can result when overlooking this step. When it comes to ensuring the health of your mill, it’s just not worth doing it half way.

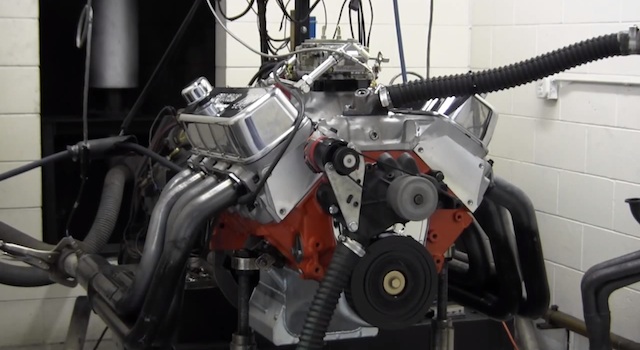

For this reason, Tri Star Engines & Transmissions of Baldwin, Wisconsin, offers a general guide to checking back pressure. Remarkably, the process may not be as complicated as you may think. When it comes to V-style engines specifically, Tri Star recommends removing the front oxygen sensor, with removal of catalytic converters as the first step.

Any low-pressure gauge will suffice when checking the back pressure between your engine and it’s converter, but if you own a back pressure test gauge then that’s even better.

Any low-pressure gauge will suffice when checking the back pressure between your engine and it’s converter, but if you own a back pressure test gauge then that’s even better.

The next step is to warm the engine and run it at a steady pace of 2,200 rpm, checking the pressure gauge for a window of 1-2 pounds with 2 pounds of pressure or more indicating a very possible exhaust restriction.

Tri Star indicates that taking these necessary steps are important because a new engine warranty, no matter where you buy it from, will not cover damage or failure caused by a restrictive exhaust.

This is just a brief summary of what’s involved, but for more detailed information of the back pressure procedure make sure to consult Tri Star directly to make sure you’ve taken the steps needed for your engine’s setup.

When it comes to the performance and overall health of your engine, sparing details can prove to be quite costly. Make sure that you do it right, and the first time!